Method for controllably preparing FeNi3 micro-nano materials in various shapes

A technology of micro-nano and morphology, which is applied in the field of controllable preparation of FeNi3 micro-nano materials with various shapes, can solve the problems of unsuitability for large-scale production, expensive equipment and instruments, and cumbersome preparation process, so as to save raw material costs and selectivity. High and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A controllable preparation of FeNi with various morphologies 3 The method for micro-nano material, comprises the following steps:

[0029] (1) Using ferric chloride hexahydrate as iron source and nickel dichloride hexahydrate as nickel source, prepare Fe 3+ The concentration is 0.01 mol / L, Ni 2+ A solution with a concentration of 0.03mol / L. Pour 37 mL of the prepared solution into another container and stir;

[0030] (2) Add 0.1 g of solid sodium hydroxide to the solution prepared in step (1), and stir thoroughly;

[0031] (3) Add 3 mL of hydrazine hydrate (80%, volume percentage) dropwise into the solution obtained in step (2), and stir thoroughly;

[0032] (4) Transfer the solution obtained in step (3) to a 50 mL reactor, seal it, and react at 170°C for 24 h;

[0033] (5) After the reaction, the product was separated with a magnet, washed five times with deionized water and absolute ethanol, and then dried in air at room temperature.

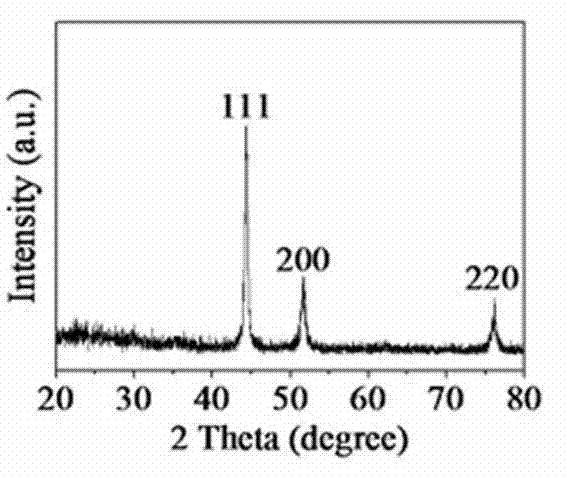

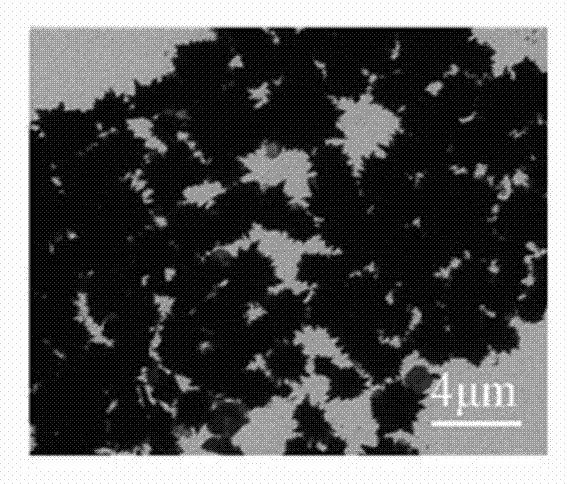

[0034] The dried samples w...

Embodiment 2

[0036] A controllable preparation of FeNi with various morphologies 3 The method for micro-nano material, comprises the following steps:

[0037] (1) Using ferric chloride hexahydrate as iron source and nickel dichloride hexahydrate as nickel source, prepare Fe 3+ The concentration is 0.01 mol / L, Ni 2+ For a solution with a concentration of 0.03mol / L, pour 38 mL of the prepared solution into another container and stir;

[0038] (2) Add 0.3 g of sodium hydroxide solid to the solution prepared in step (1), and stir thoroughly;

[0039] (3) Add 2 mL of hydrazine hydrate (80%, volume percentage) dropwise into the solution obtained in step (2), and stir thoroughly;

[0040] (4) Transfer the solution obtained in step (3) to a 50 mL reactor, seal it, and react at 170°C for 2 h;

[0041] (5) After the reaction, the product was separated with a magnet, washed five times with deionized water and absolute ethanol, and then dried in air at room temperature.

[0042] The dried samples...

Embodiment 3

[0044] A controllable preparation of FeNi with various morphologies 3 The method for micro-nano material, comprises the following steps:

[0045] (1) Using ferric chloride hexahydrate as iron source and nickel dichloride hexahydrate as nickel source, prepare Fe 3+ The concentration is 0.005 mol / L, Ni 2+ For a solution with a concentration of 0.015mol / L, pour 39 mL of the prepared solution into another container and stir;

[0046] (2) Add 0.1 g of solid sodium hydroxide to the solution prepared in step (1), and stir thoroughly;

[0047] (3) Add 1 mL of hydrazine hydrate (80%, volume percentage) dropwise into the solution obtained in step (2), and stir thoroughly;

[0048] (4) Transfer the solution obtained in step (3) to a 50 mL reactor, seal it, and react at 150 °C for 10 h;

[0049] (5) After the reaction, the product was separated with a magnet, washed five times with deionized water and absolute ethanol, and then dried in air at room temperature.

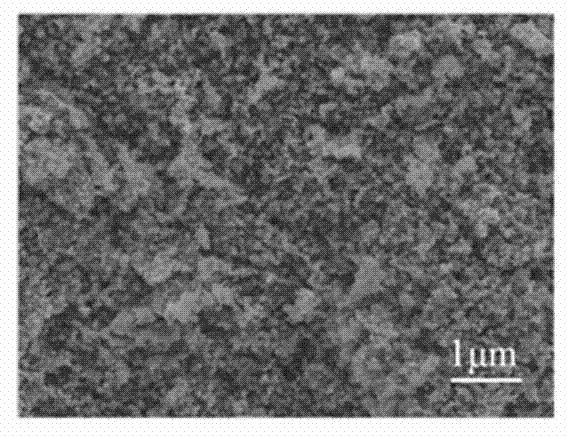

[0050] The dried sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com