Preparation method of aromatic conjugated polymer

A conjugated polymer and aromatic technology, applied in the polymer field, can solve the problems of uncontrollable molecular weight, wide molecular weight distribution and poor solubility of polymer products, and achieve the effects of good solubility, simple preparation method and few by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention provides a kind of preparation method of aromatic conjugated polymer, comprises the following steps:

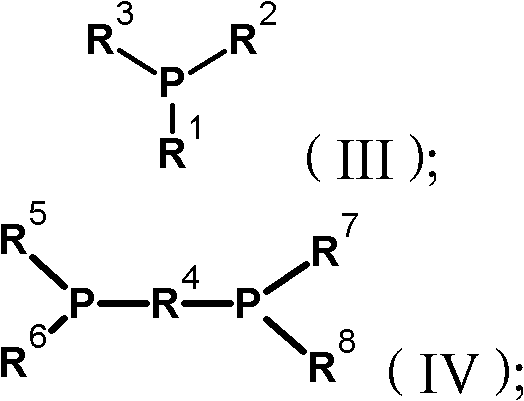

[0047] The first halogenated aromatic Grignard reagent monomer undergoes polycondensation reaction under the action of a catalyst to obtain an aromatic conjugated polymer. The catalyst is composed of a divalent nickel compound and an organic phosphine ligand. The divalent nickel compound and the described The molar ratio of organic phosphine ligand is 1: (0.5~3);

[0048] The divalent nickel compound is nickel dichloride, nickel dibromide, nickel acetylacetonate, nickel acetate or nickel perchlorate;

[0049] The first halogenated aromatic Grignard reagent monomer has a structure of formula (I):

[0050] x 1 -Q 1 -MgX 2 (I);

[0051] Among them, X 1 、X 2 independently selected from halogen;

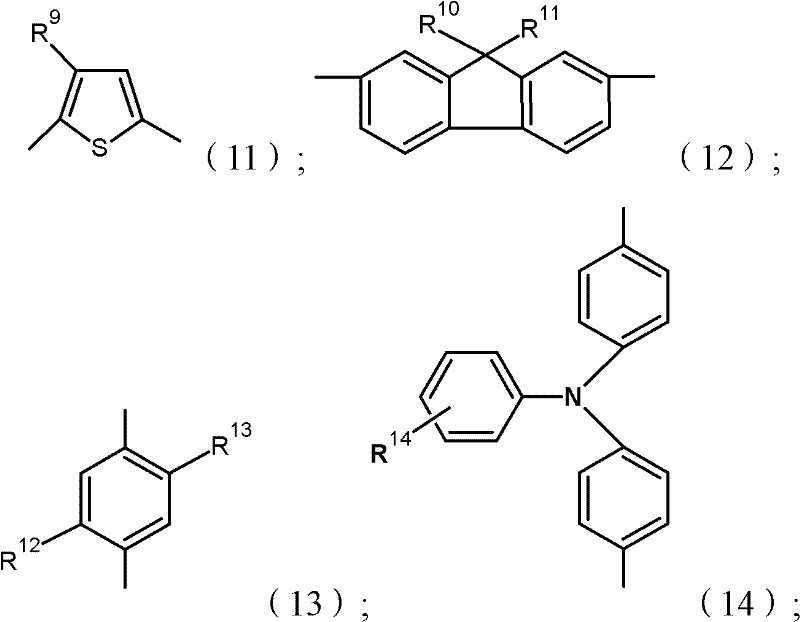

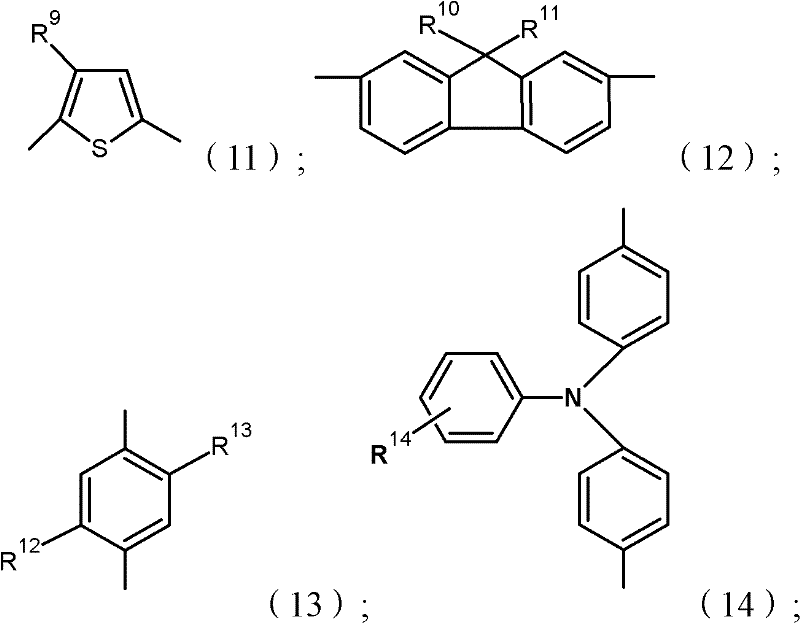

[0052] Q 1 is an aromatic group or a substituted aromatic group.

[0053] In the present invention, the first halogenated aromatic Grignard reagent m...

Embodiment 6

[0119] Under the protection of an inert gas, in the reaction vessel equipped with the 2-bromo-7-magnesium chloride-9,9-dioctylfluorene prepared in Example 5, add 1.0 ml of the tetrahydrofuran solution of the catalyst prepared in Example 1 to make the The molar ratio of the catalyst to 2-bromo-7magnesium chloride-9,9-dioctylfluorene is 2:100, the reaction system is transferred to an ice-water bath, stirred for 0.5 hours, and 10 milliliters of hydrochloric acid aqueous solution of 5 mol / L is added Quenching the reaction, extracting the resulting reaction mixture with chloroform, then washing the extracted organic layer with saturated brine, drying over anhydrous magnesium sulfate, removing the solvent, and dropping the obtained reaction product solution into stirring methanol for After settling, the volume ratio of the reaction product solution to methanol was 1:20. After filtration, 282 mg of yellow flocculent poly(9,9-dioctylfluorene) was obtained with a yield of 73%.

[0120]...

Embodiment 7

[0122] Under the protection of an inert atmosphere, in the reaction vessel equipped with the 2-bromo-7-magnesium chloride-9,9-dioctylfluorene prepared in Example 5, add 1.0 ml of the tetrahydrofuran solution of the catalyst prepared in Example 2 to make the catalyst The molar ratio of 2-bromo-7 magnesium chloride-9,9-dioctylfluorene is 2:100, the reaction system is transferred to an ice-water bath, stirred for 0.5 hours, and quenched by adding 10 ml of aqueous hydrochloric acid with a concentration of 5 mol / L reaction, the obtained reaction mixture was extracted with chloroform, and then the extracted organic layer was washed with saturated brine, dried over anhydrous magnesium sulfate, and the obtained reaction product solution was dropped into stirring methanol for precipitation after removing the solvent, The volume ratio of the reaction product solution to methanol was 1:20, and 254 mg of yellow flocculent poly(9,9-dioctylfluorene) was obtained after filtration with a yield...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com