Method for preparing nickel-iron sulfide nano-composite electrode through one-step electrodeposition

A technology of electrodepositing nickel and iron sulfide, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of poor rate retention and poor conductivity of binary metal sulfides, and improve conductivity , Improving cycle stability and rate performance, and the effect of great application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method for a one-step electrodeposited nickel-iron sulfide nanocomposite electrode, comprising:

[0040] (1) Pretreatment of carbon fiber cloth:

[0041] Cut the carbon fiber cloth into graphics of uniform size, for example, cut into strips with a size of 3cm×20cm;

[0042] Sonicate in a mixture of acetone and ethanol for 1 hour to remove dust;

[0043] After washing, immerse in an oil bath with a concentration of 5% potassium permanganate solution, the temperature of the oil bath is 80°C, and the soaking time is 40 minutes;

[0044] Ultrapure water is then used for ultrasonic cleaning until the lotion is clear and transparent, and finally dried in an oven at 60°C;

[0045] (2) Preparation of electrodeposition solution:

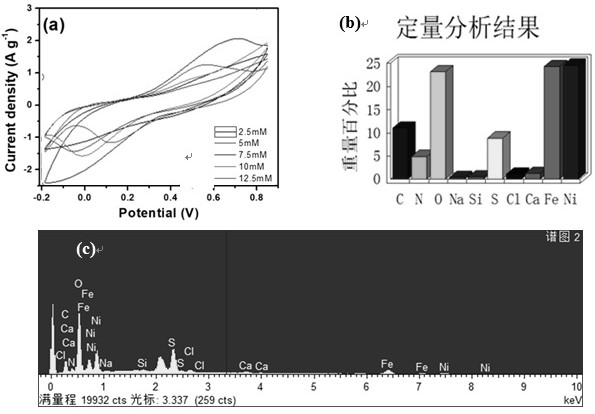

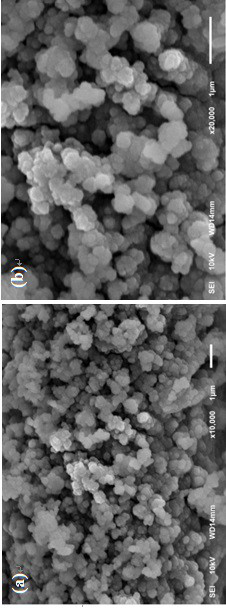

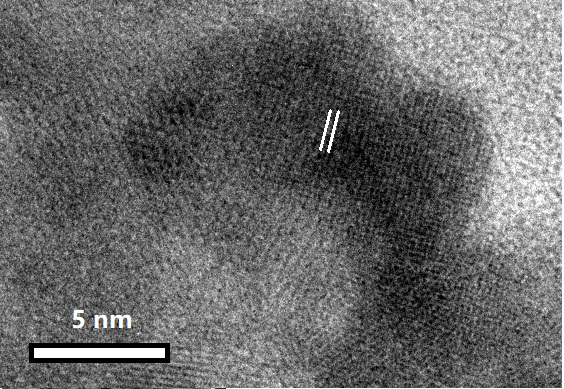

[0046] Electrochemical co-deposition of Ni-Fe-S on flexible carbon cloth with woven carbon fiber construction;

[0047] The electrodeposition solution contains ferric chloride hexahydrate and different concentrations of nickel dichlor...

Embodiment 2

[0052] A preparation method for a one-step electrodeposited nickel-iron sulfide nanocomposite electrode, comprising:

[0053] (1) Pretreatment of carbon fiber cloth:

[0054] Cut the carbon fiber cloth into graphics of uniform size, for example, cut into strips with a size of 3cm×20cm;

[0055] Ultrasound in acetone and ethanol mixed solution for 2 hours to remove dust;

[0056] After washing, immerse in an oil bath with a concentration of 5% potassium permanganate solution, the temperature of the oil bath is 90°C, and the soaking time is 50 minutes;

[0057] Ultrasonic cleaning is then performed with ultrapure water until the lotion is clear and transparent, and finally dried in an oven at 80°C;

[0058] (2) Preparation of electrodeposition solution:

[0059] Electrochemical co-deposition of Ni-Fe-S on flexible carbon cloth with woven carbon fiber construction;

[0060] The electrodeposition solution contains ferric chloride hexahydrate and different concentrations of nic...

Embodiment 3

[0065] A preparation method for a one-step electrodeposited nickel-iron sulfide nanocomposite electrode, comprising:

[0066] (1) Pretreatment of carbon fiber cloth:

[0067] Cut the carbon fiber cloth into graphics of uniform size, for example, cut into strips with a size of 3 cm×20 cm;

[0068] Ultrasonic in acetone and ethanol mixed solution for 1.5 hours to remove dust;

[0069] After washing, immerse in an oil bath with a concentration of 5% potassium permanganate solution, the temperature of the oil bath is 85°C, and the soaking time is 45 minutes;

[0070] Ultrasonic cleaning is then performed with ultrapure water until the lotion is clear and transparent, and finally dried in an oven at 70°C;

[0071] (2) Preparation of electrodeposition solution:

[0072] Electrochemical co-deposition of Ni-Fe-S on flexible carbon cloth with woven carbon fiber construction;

[0073] The electrodeposition solution contains ferric chloride hexahydrate and different concentrations of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com