Thermal battery nickel dichloride positive electrode film material and preparation method thereof

A technology of nickel dichloride and thermal battery, which is applied to the electrodes of primary batteries, electrode manufacturing, battery electrodes, etc., which can solve the problems of poor preparation and molding of nickel chloride powder electrodes, and achieve light weight, reduced thickness, and small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

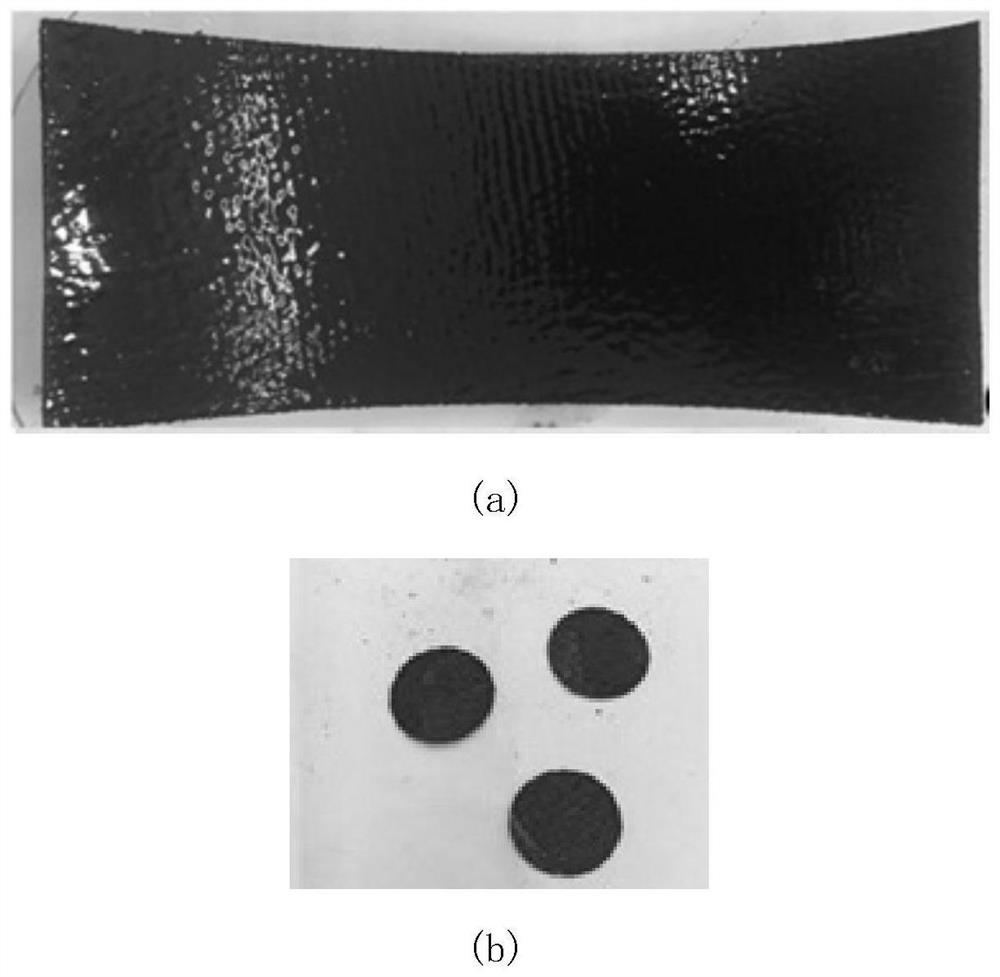

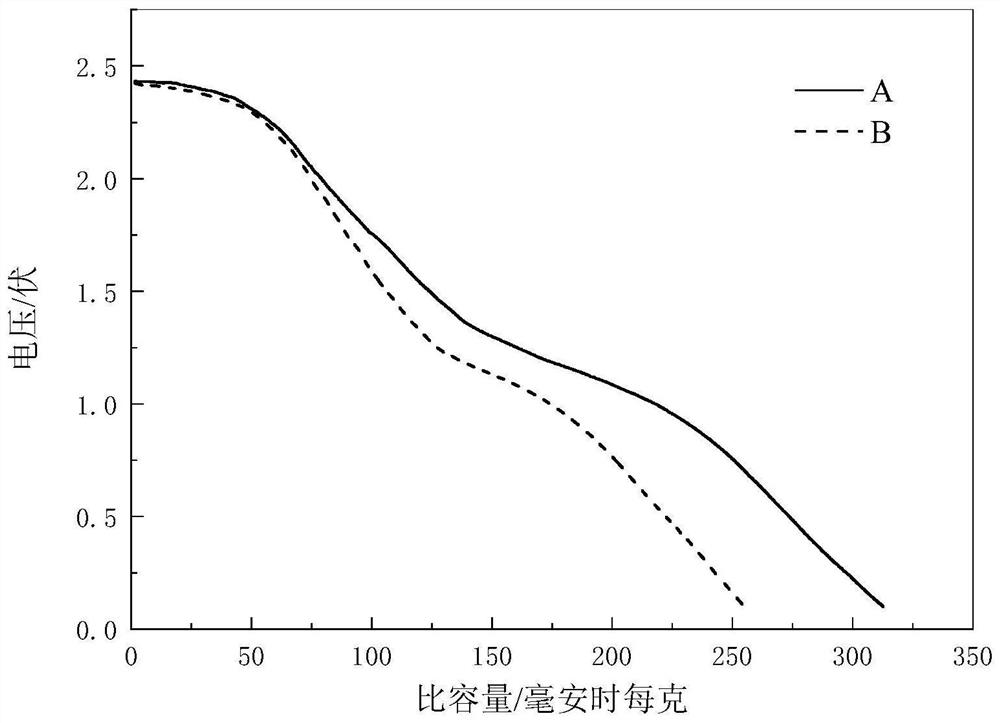

[0025] Weigh 14g nickel dichloride powder, 2g conductive agent activated carbon, 2gLiCl-LiBr-NaCl-KCl low temperature eutectic salt electrolyte, 1.9g binder MgO, 0.1g binder gas phase SiO 2 After mixing evenly, add 15ml of absolute ethanol, stir for 30 minutes, adjust the viscosity of the mixture to make it a paste and have a certain viscosity, and then use a 100-mesh screen printing machine to make the paste mixture evenly distributed and adsorbed to the surface of the porous conductive material. The substrate with the active material was placed in a vacuum drying oven and dried in vacuum at 180° C. for 4 hours to obtain a large-area thermal battery thin film positive electrode. Under the protection of a dry gas with a relative humidity of 1%, the positive electrode sheet was flat-pressed with an electrode tablet press at 20 MPa, and then punched with an electrode punching machine to obtain a number of thin film positive electrodes with a thickness of 0.4 mm and a diameter of ...

Embodiment 2

[0029] Weigh 14g nickel dichloride powder, 2g conductive agent activated carbon, 2gLiCl-LiBr-NaCl-KCl low temperature eutectic salt electrolyte, 1.8g binder MgO, 0.2g binder gas phase SiO 2 After mixing evenly, add 15ml of absolute ethanol, stir for 30 minutes, adjust the viscosity of the mixture to make it a paste and have a certain viscosity, and then use a 100-mesh screen printing machine to make the paste mixture evenly distributed and adsorbed to the surface of the porous conductive material. The substrate with the active material was placed in a vacuum drying oven and dried in vacuum at 180° C. for 4 hours to obtain a large-area thermal battery thin film positive electrode. Under the protection of a dry gas with a relative humidity of 1%, the positive electrode sheet was flat-pressed with an electrode tablet press at 20 MPa, and then punched with an electrode punching machine to obtain a number of thin film positive electrodes with a thickness of 0.4 mm and a diameter of ...

Embodiment 3

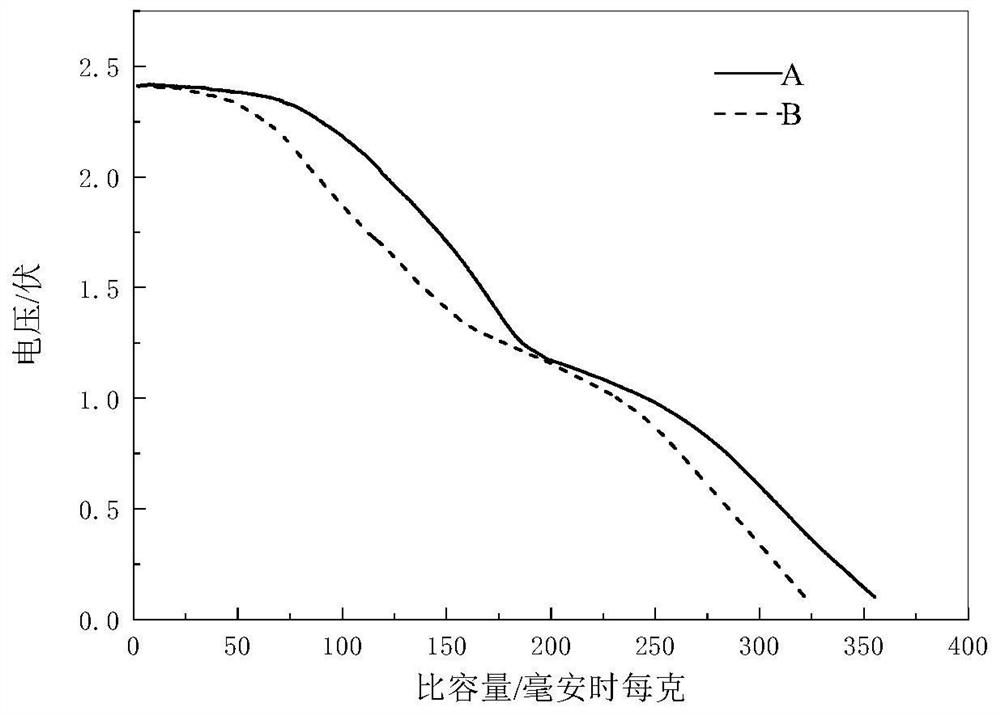

[0033] Weigh 14g of nickel dichloride powder, 2g of conductive agent activated carbon, 2g of LiCl-LiBr-NaCl-KCl low-temperature eutectic salt electrolyte, 2g of binder MgO, mix well, add 15ml of absolute ethanol, stir for 30min, and adjust the viscosity of the mixture. Make it into a paste and have a certain viscosity, then use a 100-mesh screen printing machine to make the paste mixture evenly distributed and adsorbed on the surface of the porous conductive material, put the substrate covered with the active material into a vacuum drying oven and dry it under vacuum at 180°C After 4h, a large-area thermal battery thin film positive electrode was obtained. Under the protection of a dry gas with a relative humidity of 1%, the positive electrode sheet was flat-pressed with an electrode tablet press at 20 MPa, and then punched with an electrode punching machine to obtain a number of thin film positive electrodes with a thickness of 0.4 mm and a diameter of 19 mm.

[0034] Under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com