Cobalt-nickel zeolite imidazolate framework-derived porous carbon for biomethane production

A technology of zeolite imidazolate and biomethane, which is applied in the field of biomass energy utilization, can solve the problems of poor microbial electron transfer performance, small particle size of metal nanoparticles, unfavorable attachment and immobilization of fermenting microorganisms, etc., to achieve optimal electron transfer performance, Enhancing the effect of interspecies electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

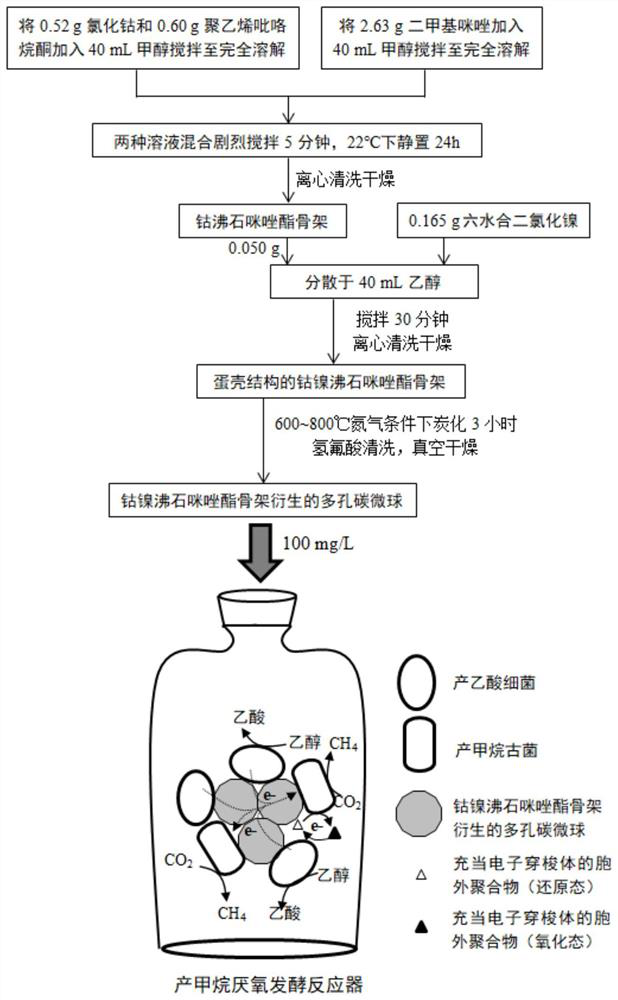

[0034] Weigh 0.52g of cobalt chloride and 0.60g of polyvinylpyrrolidone, add 40mL of methanol and stir until completely dissolved. Then weigh 2.63g of dimethylimidazole, add 40mL of methanol and stir until completely dissolved. Then the above two solutions were mixed and vigorously stirred for 5 minutes, aged at 22° C. for 24 hours to obtain the cobalt zeolite imidazolate framework. Collect by centrifugation at 8000rpm for 5min, wash with methanol three times, and dry under vacuum at 60°C for 24 hours. Take 0.050 g of the cobalt zeolite imidazolate skeleton powder obtained by grinding after drying, disperse it in 40 mL of ethanol and add 0.165 g of nickel dichloride hexahydrate, stir for 30 minutes to form the cobalt nickel zeolite imidazolate skeleton of eggshell structure, and centrifuge to collect the precipitate. Vacuum dried at 60°C for 12 hours. The synthesized cobalt-nickel zeolite imidazolate framework was placed in a tube furnace, and carbonized at 600°C and nitroge...

Embodiment 2

[0036] Weigh 0.52g of cobalt chloride and 0.60g of polyvinylpyrrolidone, add 40mL of methanol and stir until completely dissolved. Then weigh 2.63g of dimethylimidazole, add 40mL of methanol and stir until completely dissolved. Then the above two solutions were mixed and vigorously stirred for 5 minutes, aged at 22° C. for 24 hours to obtain the cobalt zeolite imidazolate framework. Collect by centrifugation at 8000rpm for 5min, wash with methanol three times, and dry under vacuum at 60°C for 24 hours. Take 0.050 g of the cobalt zeolite imidazolate skeleton powder obtained by grinding after drying, disperse it in 40 mL of ethanol and add 0.165 g of nickel dichloride hexahydrate, stir for 30 minutes to form the cobalt nickel zeolite imidazolate skeleton of eggshell structure, and centrifuge to collect the precipitate. Vacuum dried at 60°C for 12 hours. The synthesized cobalt-nickel zeolite imidazolate framework was placed in a tube furnace, and carbonized at a temperature of ...

Embodiment 3

[0038] Weigh 0.52g of cobalt chloride and 0.60g of polyvinylpyrrolidone, add 40mL of methanol and stir until completely dissolved. Then weigh 2.63g of dimethylimidazole, add 40mL of methanol and stir until completely dissolved. Then the above two solutions were mixed and vigorously stirred for 5 minutes, aged at 22° C. for 24 hours to obtain the cobalt zeolite imidazolate framework. Collect by centrifugation at 8000rpm for 5min, wash with methanol three times, and dry under vacuum at 60°C for 24 hours. Take 0.050 g of the cobalt zeolite imidazolate skeleton powder obtained by grinding after drying, disperse it in 40 mL of ethanol and add 0.165 g of nickel dichloride hexahydrate, stir for 30 minutes to form the cobalt nickel zeolite imidazolate skeleton of eggshell structure, and centrifuge to collect the precipitate. Vacuum dried at 60°C for 12 hours. The synthesized cobalt-nickel zeolite imidazolate framework was placed in a tube furnace, and carbonized at 800°C and nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com