Sphericized hexanitrohexaazaisowurtzitane (HNIW) crystal and preparation method thereof

A technology of hexanitrohexaazane and isowurtzitane, which is applied in the field of spherical hexanitrohexaazaisowurtzitane crystals and preparation of such spherical hexanitrohexaazaisowurtzitane crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] In the present invention, unless otherwise specified, the percentages described in the present invention are percentages by weight. The following specific examples are used to illustrate the present invention, but not to limit the present invention.

Embodiment 1

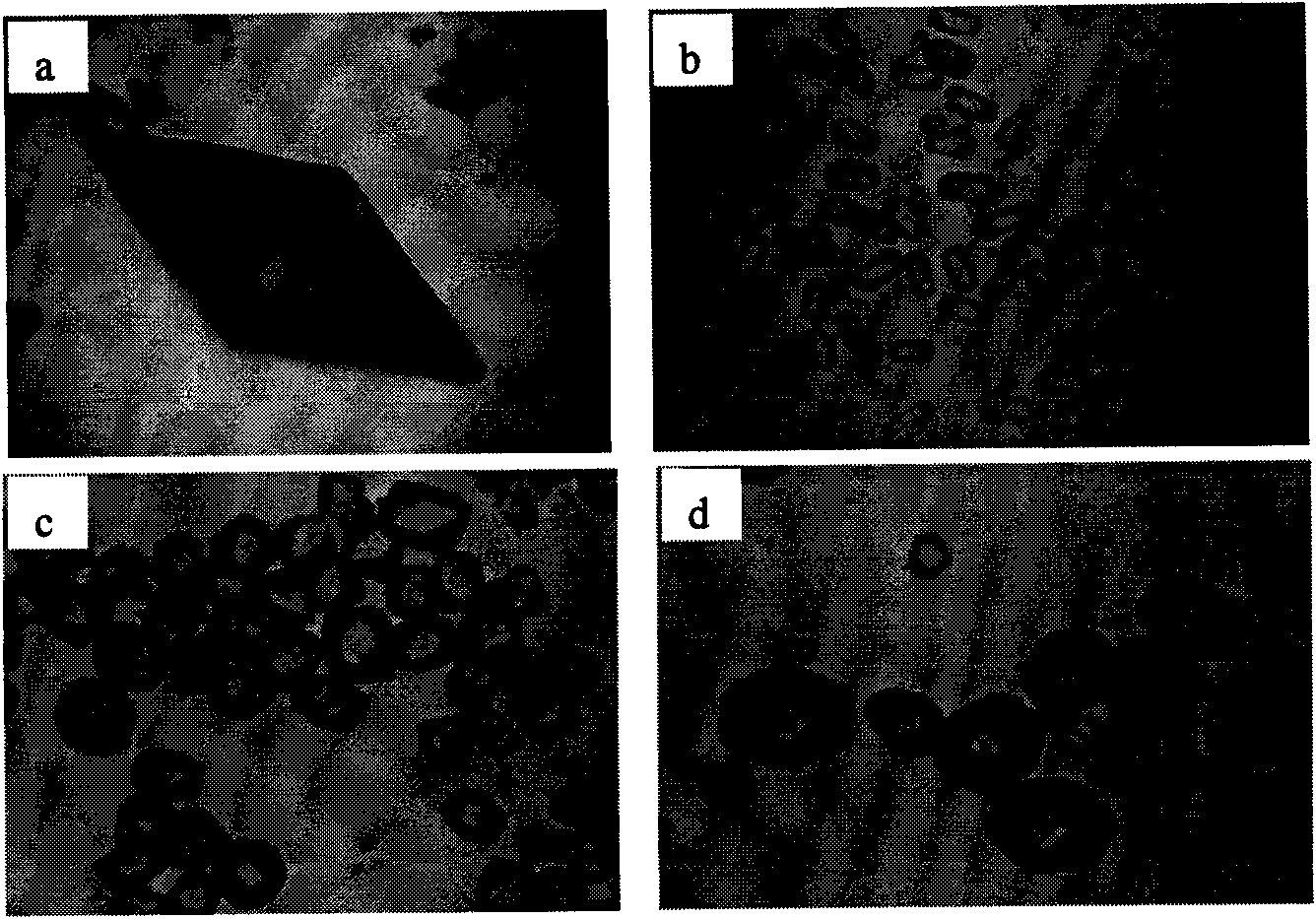

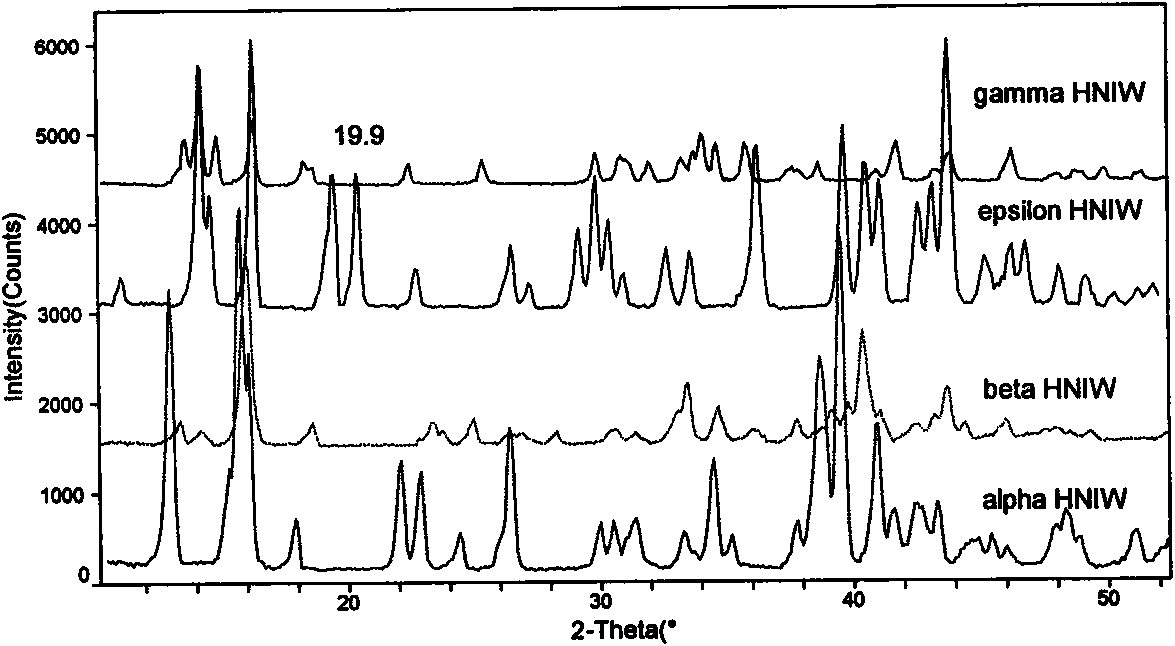

[0042] Add 10g of γ-HNIW into 20ml of ethyl acetate in a three-neck flask, dissolve and filter. Add 0.1 g of maleic acid to ethyl acetate and stir to dissolve it. After adding 8 ml of chloroform dropwise, add 1 g of ε-HNIW seed crystals, and then add 160 ml of chloroform. The addition of chloroform is completed within 21 hours to release all the dissolved HNIW. The crystallization temperature is 20-25°C. The ε-HNIW crystal obtained by crystallization has no sharp edges and corners, and its shape is a polyhedral sphere. Shock Sensitivity H 50 is 41 cm.

Embodiment 2

[0044] Add 10g of γ-HNIW into 20ml of ethyl acetate in a three-neck flask, dissolve and filter to remove undissolved impurities. 0.12 g of pentaerythritol was added to ethyl acetate, stirred and dissolved. After adding 8ml of chloroform dropwise, add 1g of ε-HNIW seed crystals, and then add 160ml of chloroform. The addition of chloroform is completed within 20 hours to release all the dissolved HNIW. The crystallization temperature is 20-25°C. The ε-HNIW crystal obtained by crystallization has no sharp edges and corners, and its shape is a polyhedral sphere. Shock Sensitivity H 50 is 31 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com