Preparation of high purity high dense polycrystal CeB6 block cathode material

A cathode material, high-purity technology, applied in the direction of boron/boride, metal boride, etc., can solve the problems of affecting the emission performance of materials, low bulk purity, and high production cost, saving sintering time, improving purity, and improving Density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Vacuumize the reaction chamber of the DC arc evaporation and condensation equipment to 3.0×10 -3 After Pa, fill in hydrogen and argon with a volume ratio of 3:1 and a total pressure of 0.1MPa, with metal tungsten as the cathode and elemental cerium block as the anode, under the conditions of reaction current 80A, arc voltage 45V, and reaction time 20min Prepare the cerium hydride nanopowder whose particle size is 20-40nm;

[0020] 2) After grinding and mixing cerium hydride nanopowder and boron powder (20-50nm) in a pretreatment chamber with an oxygen content of 10ppm according to a mass ratio of 1:0.456, put them into a graphite mold;

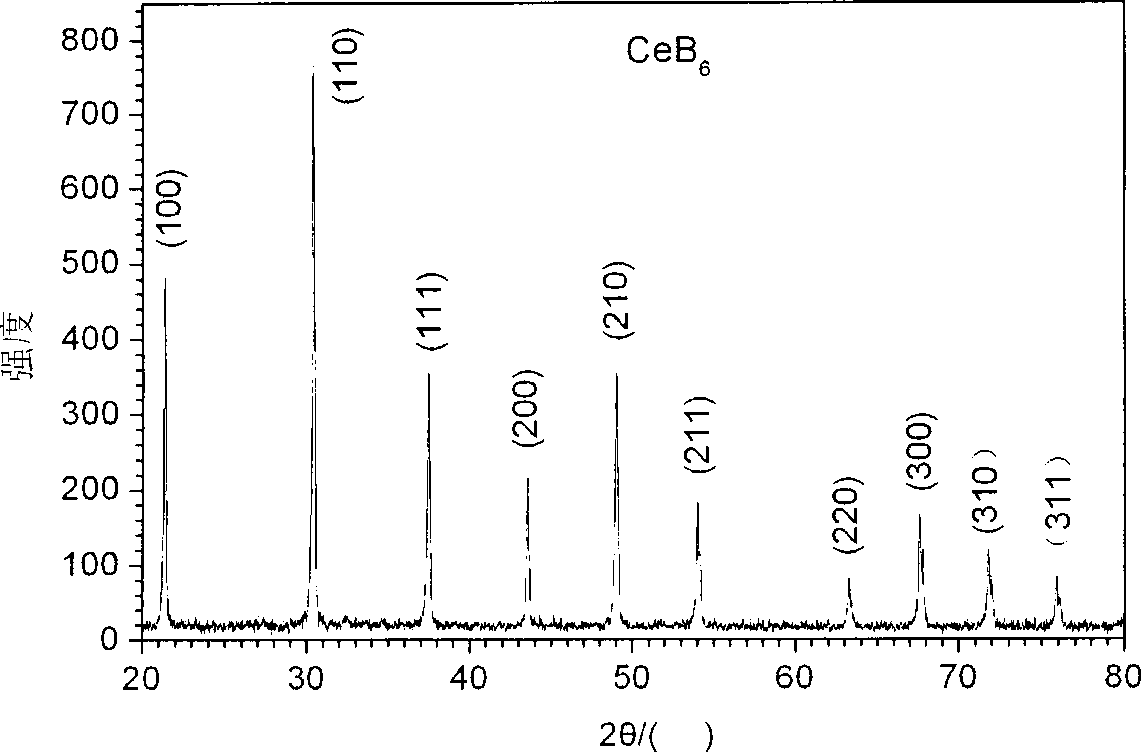

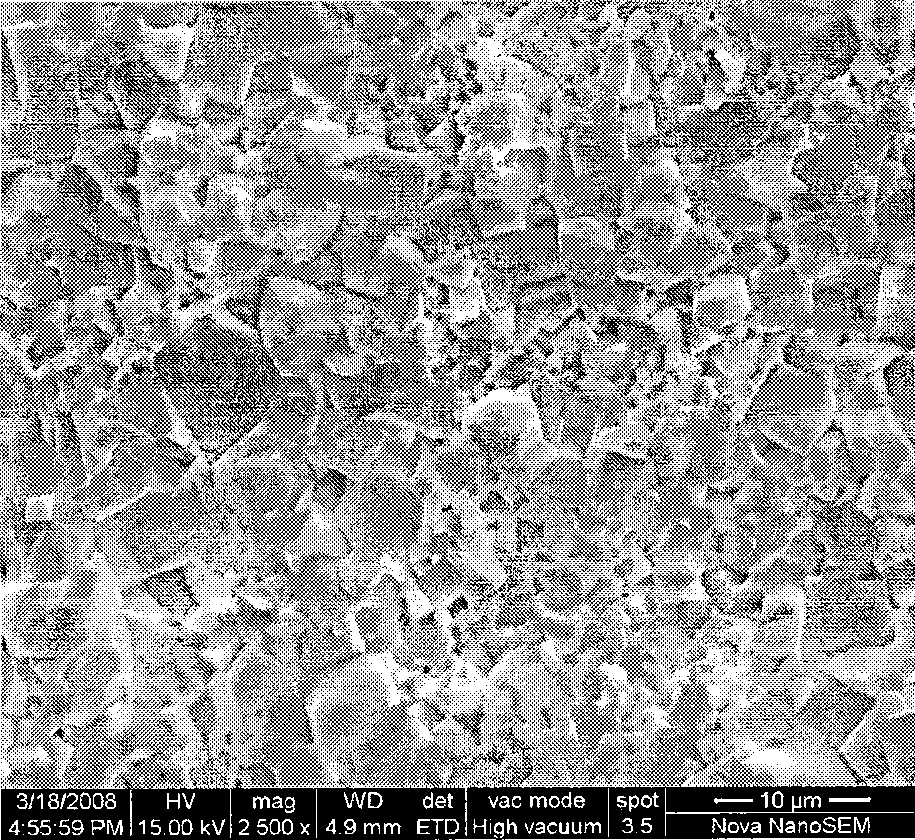

[0021] 3) Put the graphite mold into the SPS sintering equipment for sintering. The sintering process is as follows: the sintering atmosphere is a vacuum of 5Pa, the sintering pressure is 30MPa, the sintering temperature is 1300°C, the heating rate is 80°C / min, and the heat preservation is 20min. Cooling to obtain high-purity and hi...

Embodiment 2

[0024] 1) Vacuumize the reaction chamber of the DC arc evaporation and condensation equipment to 5.0×10 -3 After Pa, fill it with hydrogen and argon with a volume ratio of 1:1 and a total pressure of 0.1MPa, with metal tungsten as the cathode and elemental metal cerium as the anode, under the conditions of reaction current 150A, arc voltage 20V, and reaction time 30min Prepare the cerium hydride nanopowder whose particle size is 30~60nm;

[0025] 2) After grinding and mixing cerium hydride nanopowder and boron powder (20-50nm) in a pretreatment chamber with an oxygen content of 50ppm according to a mass ratio of 1:0.456, put them into a graphite mold;

[0026] 3) Put the graphite mold into the SPS sintering equipment for sintering. The sintering process is as follows: the sintering atmosphere is a vacuum of 5Pa, the sintering pressure is 50MPa, the sintering temperature is 1500°C, the heating rate is 140°C / min, and the heat preservation is 12min. Cooling to obtain high-purity...

Embodiment 3

[0029] 1) Vacuumize the reaction chamber of the DC arc evaporation and condensation equipment to 1.0×10 -2 After Pa, fill in hydrogen and argon with a volume ratio of 4:1 and a total pressure of 0.1MPa, with metal tungsten as the cathode and elemental metal cerium as the anode, under the conditions of reaction current 90A, arc voltage 30V, and reaction time 40min Prepare the cerium hydride nano-powder whose particle size is 20-50nm;

[0030] 2) Grinding and mixing cerium hydride nanopowder and boron powder (2-10 μm) in a pretreatment chamber with an oxygen content of 80 ppm according to a mass ratio of 1:0.456, and then putting them into a graphite mold;

[0031] 3) Put the graphite mold into the SPS sintering equipment for sintering. The sintering process is as follows: the sintering atmosphere is 0.1MPa high-purity argon atmosphere with a purity of 99.999%, the sintering pressure is 60MPa, the sintering temperature is 1700°C, and the heating rate is 200 ℃ / min, hold for 3 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com