Carbon black master batch, preparation method and application thereof

A carbon black masterbatch and carbon black technology, which is applied in the field of plastic coloring, can solve the problems such as the deterioration of pressure pipes and the formation of unsmooth surfaces, and achieve the effects of less addition, improved quality and service life, and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

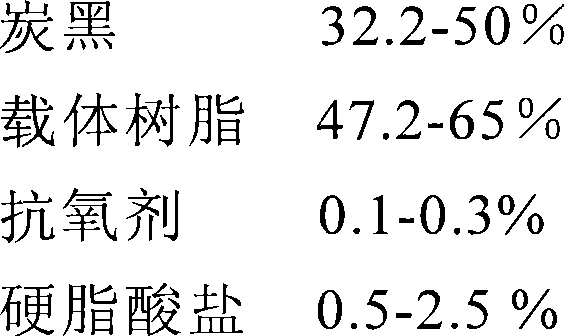

Image

Examples

Embodiment 1

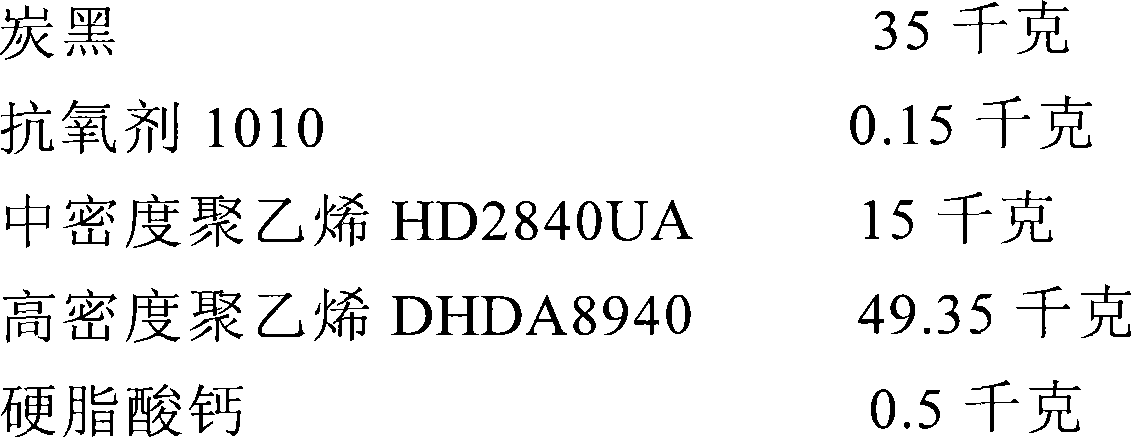

[0022] Embodiment 1: prepare 100 kilograms and be specially used in the carbon black masterbatch A that water supply polyethylene (PE) pipe is useful

[0023] 1. The weight of each component is:

[0024]

[0025] The carbon black is high-purity furnace carbon black, the particle size of the carbon black pigment is 20nm; the toluene extract is less than 0.03%, the total sulfur content is less than 0.1%, and the residue on a 325-mesh sieve is less than 20ppm;

[0026] 2. Preparation method:

[0027] First add each component to the automatic weighing and feeding system, and use multiple loss-in-weight continuous metering electronic scales to strictly mix various materials according to the process, and automatically add them to the double-rotor continuous internal mixing extruder with a speed of 300-500 / min After fully kneading, shearing and dispersing, fall into the single-screw extruder to extrude, after cooling, pelletizing and dehydration, the resulting carbon black master...

Embodiment 2

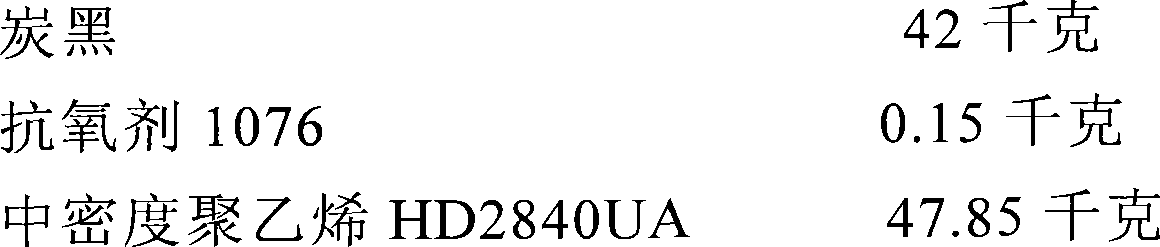

[0031] Embodiment 2: prepare 100 kilograms and be specially used in the carbon black masterbatch B that water supply polyethylene (PE) pipe is useful

[0032] 1. The weight of each component is:

[0033]

[0034]

[0035] The carbon black is high-purity furnace carbon black, the particle size of the carbon black pigment is 25nm; the toluene extract is less than 0.03%, the total sulfur content is less than 0.1%, and the residue on a 325-mesh sieve is less than 20ppm;

[0036] 2. preparation method: with embodiment 1

[0037] The carbon black master batch B prepared in this way has a carbon black content of 42%, a carbon black dispersibility of <2 grades, and a melt index of 35 (21.6 kg and 190° C.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com