Release control urea and its preparing process

A technology of urea and large granular urea, which is applied in the fields of agricultural gas emission reduction, fertilizer mixtures, fertilization devices, etc., can solve the problems of loss, changes in the application effects of urease inhibitors and nitrification inhibitors, and reduction of urea hydrolysis and nitrification inhibition effects. , to achieve the effect of improving utilization, reducing possibility and reducing release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

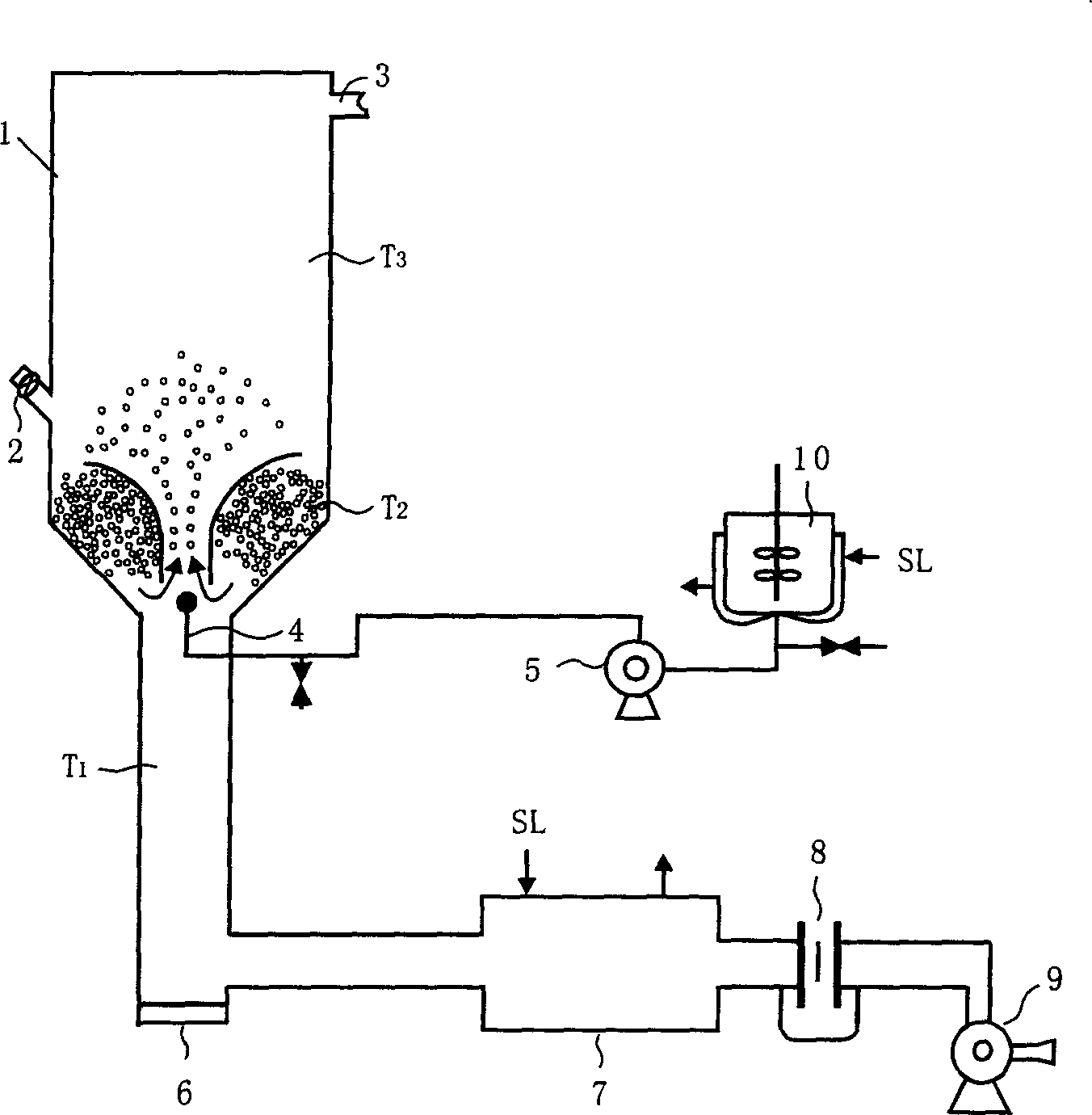

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Coating and urease inhibitor combined type control effect urea (the fat core urea is the large granular urea with a particle size of 2.5 to 4.0mm)

[0019] Adopt fluidized bed spray coating method, dissolve 100 parts of acrylic resin RS100 used for coating in 1500 parts of ethanol solvent, wherein the amount of acrylic resin RS100 is 8% of the weight of the fertilizer core; then add 5 parts of urease to this solution to inhibit Agent hydroquinone, 10 parts of inorganic membrane conditioning agent talcum powder, then add 5 parts of plasticizer dimethyl phthalate of total weight of the solution, pour into fluidized bed liquid tank after miscibility, spray on fluidized large On the surface of granular urea, the operating parameters of the fluidized bed coating machine are: air inlet temperature 65°C, compressed air pressure 0.4Pa, nozzle atomization pressure 0.1Pa, after about 1 hour, milky white, smooth , Continuous and uniform coating.

[0020] Its result is: ...

Embodiment 2

[0023] Example 2 Coating and Nitrification Inhibitor Combination Type Controlled Effect Urea (Fat core urea is large granular urea with a particle size of 2.5-4.0mm)

[0024] Adopt fluidized bed spray coating method, 50 parts of acrylic resin RS100 and 50 parts of ethyl cellulose for coating are miscible in 1000 parts of ethanol solvent, wherein the sum of the miscible amount of acrylic resin RS100 and ethyl cellulose is fertilizer 10% of the core weight; then add 4 parts of nitrification inhibitor dicyandiamide to this solution, 5 parts of inorganic membrane conditioner zeolite powder, and then add 4 parts of plasticizer polyethylene glycol of the total weight of the solution, after miscible Pour it into a fluidized bed liquid tank and spray it on the surface of fluidized large particle urea. The operating parameters of the fluidized bed coating machine are: inlet air temperature 75°C, compressed air pressure 0.3Pa, nozzle atomization pressure 0.15Pa, approximately After 1 ho...

Embodiment 3

[0026] Example 3 Coating, urease inhibitor, and nitrification inhibitor combined effect-controlling urea (the fat core urea is large granular urea with a particle size of 2.5 to 4.0 mm)

[0027] Adopt fluidized bed spray coating method, 65 parts of acrylic resin RS100 and 35 parts of ethyl cellulose for coating are miscible in 1300 parts of ethanol solvent, wherein the total miscible amount of acrylic resin RS100 and ethyl cellulose is fertilizer 12% of core weight; add 1 part urease inhibitor N-butylthiophosphoric triamide, 3 parts nitrification inhibitor 3,4-dimethylpyrazole phosphate, 8 parts inorganic membrane conditioner to this solution Diatomaceous earth, then add plasticizer polyethylene glycol of 3 parts of total solution weights, pour into the fluidized bed liquid tank after miscible, spray on the surface of fluidized large particle urea, wherein the fluidized bed coating machine The operating parameters are: air inlet temperature 55°C, compressed air pressure 0.5Pa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com