Heteropolyacid modified cellulose nanofiber compound, proton exchange membrane and preparation of heteropolyacid modified cellulose nanofiber compound and proton exchange membrane

A technology of proton exchange membranes and nanofibers, applied in plant fibers, fiber treatment, organic diaphragms, etc., can solve the problems that heteropolyacids cannot be directly fixed, difficult to obtain, and have high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

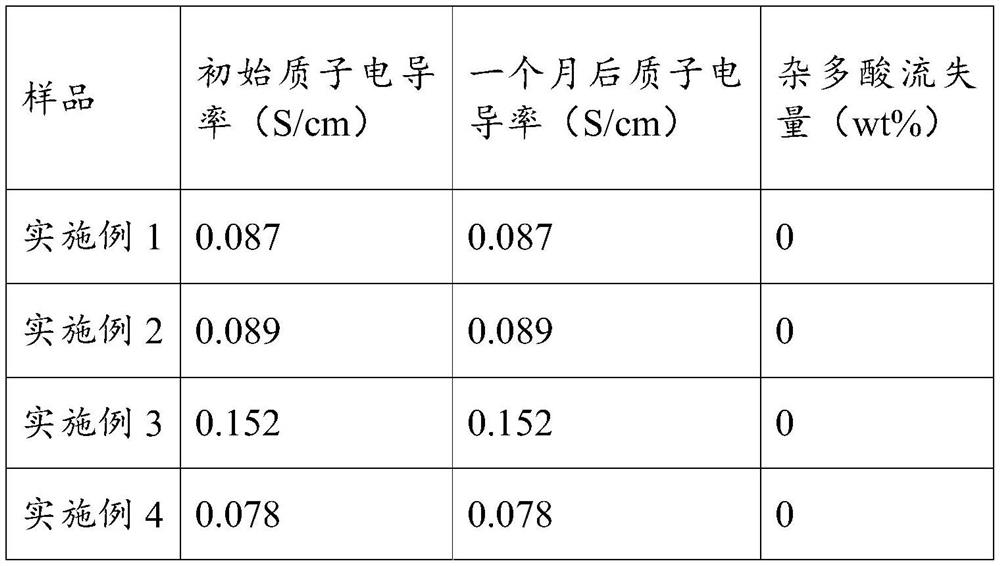

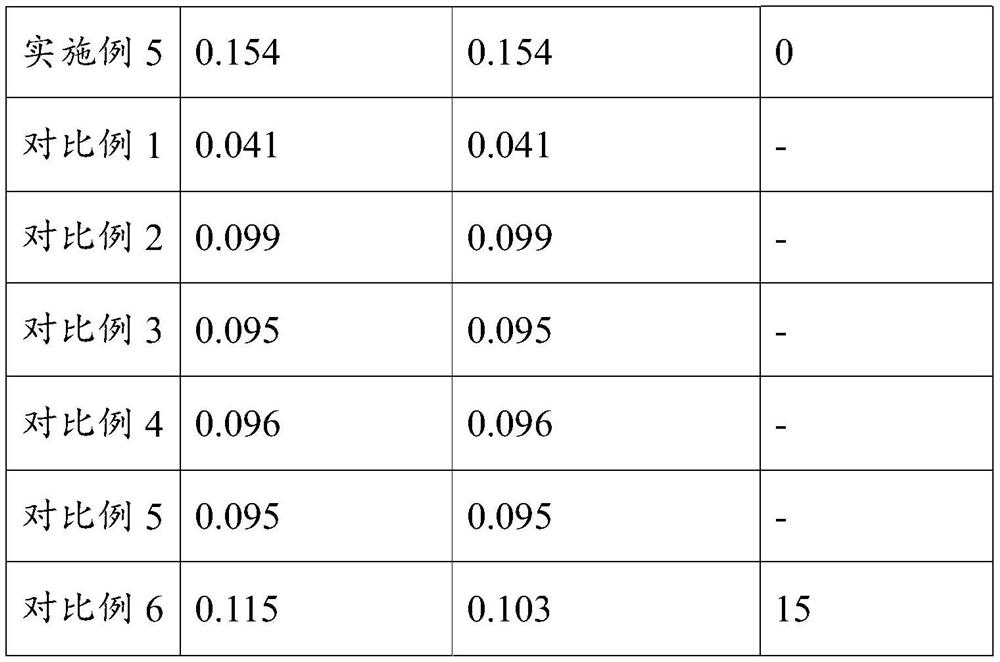

Embodiment 1

[0061] This embodiment provides a kind of preparation method of composite proton exchange membrane:

[0062] Disperse 1 g of cellulose nanofibers in 100 mL of deionized water (120 w ultrasonic for 0.5 h), after adding 0.2 g of dopamine hydrochloride and 0.2 g of tris-HCl buffer and stirring evenly, adjust the pH of the dispersion with 0.1 mol / L NaOH to 8.5. After reacting at room temperature for 24 hours, it was washed and dried to obtain polydopamine-wrapped cellulose nanofibers DC. Afterwards, take 1 g of the prepared DC powder and disperse it in 35 mL of acetic acid, add 0.25 g of trimesaldehyde and stir evenly, react at room temperature for 12 hours, separate the solid from the liquid, wash the solid with water, remove unreacted trimes, and dry Obtain a solid powder; then take 1 g of the solid powder and disperse it in 35 mL of acetic acid, add 0.184 g of 1,3,5-tris(4-aminophenyl)benzene and stir evenly, react at room temperature for 12 hours, separate the solid from the ...

Embodiment 2

[0066] This example provides a method for preparing a composite proton exchange membrane. The specific steps are basically the same as those in Example 1, except that the heteropolyacid used in this example is silicotungstic acid.

Embodiment 3

[0068] This embodiment provides a kind of preparation method of composite proton exchange membrane:

[0069] Disperse 1 g of cellulose nanofibers in 100 mL of deionized water (120 w ultrasonic for 0.5 h), after adding 0.2 g of dopamine hydrochloride and 0.2 g of tris-HCl buffer and stirring evenly, adjust the pH of the dispersion with 0.1 mol / L NaOH to 8.5. After reacting at room temperature for 24 hours, it was washed and dried to obtain polydopamine-wrapped cellulose nanofibers DC. Afterwards, take 1 g of the prepared DC powder and disperse it in 35 mL of acetic acid, add 0.25 g of trimesaldehyde and stir evenly, react at room temperature for 48 hours, separate the solid from the liquid, wash the solid with water, remove unreacted trimes, and dry Obtain a solid powder; then take 1 g of the solid powder and disperse it in 35 mL of acetic acid, add 0.184 g of 1,3,5-tris(4-aminophenyl)benzene and stir evenly, react at room temperature for 48 hours, separate the solid and liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com