Complexation extraction method of plant polyphenols substances

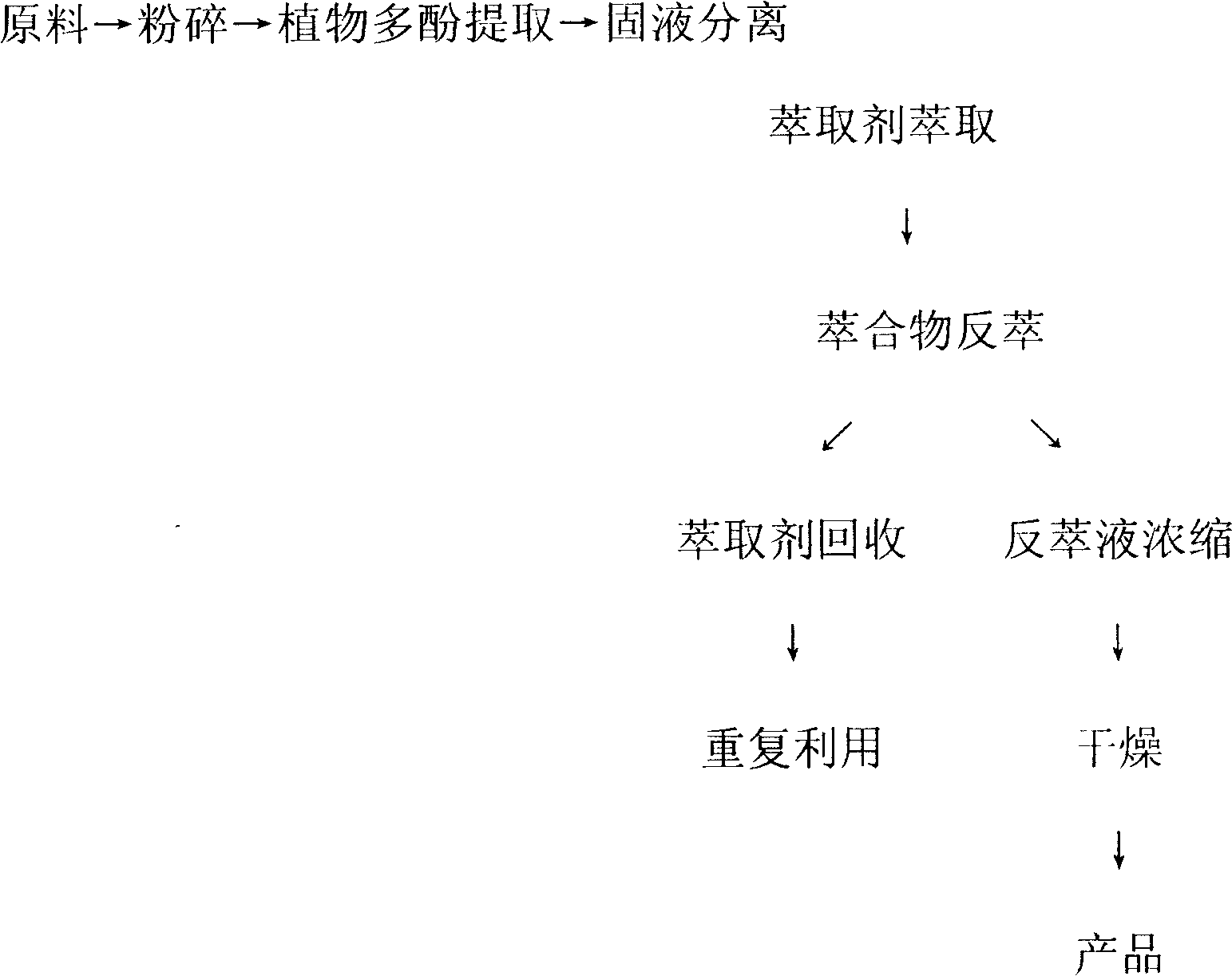

A plant polyphenol and complexing technology, applied in the field of extraction of plant polyphenols, can solve the problems of requiring special equipment for recycling, reduced biological activity of plant polyphenol molecules, low efficiency, etc., and achieves the total amount of available resources and The potential economic value is high, the process is easy to realize, and the process is simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -1

[0077] Example-1: Complex extraction of apple and prunus polyphenols

[0078] 1. Pretreatment process:

[0079] Take by weighing pomace, pericarp, fruit (wherein: apple fruit is cut into about 0.5 centimeter section, and Oli fruit is chopped after removing kernel) raw material 500 grams of apple or prunus respectively, puts in suitable container, uses Soak in 1000 ml of acidic pure water with a pH value of 34 for 30 minutes, crush it with a pulverizer for about 30 seconds, so that the particle size of the material reaches 10-20 mesh, and ultrasonically treat it for 40 minutes under the conditions of ultrasonic frequency 40KHZ, power 200W, and temperature 40°C. Filtration is obtained by filtration, and the residue can be extracted and processed 2-3 times under the same conditions and the resulting filtrates are combined; all the above-mentioned filtrates are centrifuged at 4000-4500 rpm for 10 minutes, and the residue is discarded to obtain Extraction solution;

[0080] 2. Ex...

Embodiment -2

[0087] Embodiment-2: Complex extraction of grape seed, apple seed polyphenol

[0088] 1. Pretreatment process:

[0089] Weigh 500 grams of dried grape seeds and apple seeds respectively, crush them, put them in an appropriate container, soak them in 2000 ml of acidic pure water with a pH value of 3-4 for 24 hours, and use them under the conditions of ultrasonic frequency 80KHZ, power 200W, and temperature 40°C Ultrasonic treatment for 50 minutes and filtration, the residue was extracted 2-3 times under the same conditions, and the filtrate was combined; the above filtrate was centrifuged at 4000---4500 rpm for 10-20 minutes to obtain the extract ;

[0090] 2. Extraction process:

[0091] Use a pipette to draw 48ml of trioctyl phosphate, 13ml of n-octanol, and 39ml of kerosene, mix them well, and prepare the extractant;

[0092] Use a graduated cylinder to measure 250 ml of extract solution and 250 ml of extractant, put them in a 1000 ml separatory funnel, place the separato...

Embodiment -3

[0097] Example-3: Complex Extraction of Sorghum Polyphenols

[0098] 1. Pretreatment process:

[0099] Weigh 500 grams of dried sorghum seeds or sorghum husks that have been dried and crushed through a 10-mesh sieve, put them into a suitable container, soak them in 3000 ml of acidic pure water with pH=3-4 for 24 hours, Ultrasonic treatment for 40 minutes at 40KHZ, power 200W, temperature 40°C, filter to obtain the filtrate, the residue can be extracted and processed 2-3 times under the same conditions, and the filtrate is combined; the filtrate is heated at 4000---4500 rpm Under separate conditions, centrifuge for 10 minutes to obtain the extract;

[0100] 2. Extraction process:

[0101] Use a pipette to draw 31ml of trioctyl phosphate, 39ml of n-octanol, and 30ml of kerosene, mix them well, and prepare the extractant;

[0102] Use a graduated cylinder to measure 250 ml of extract solution and 250 ml of extractant, put them in a 1000 ml separatory funnel, place the separato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com