Technology for reprocessing waste silk in polyester staple fiber production process

A technology of polyester staple fiber and production process, applied in the field of process, can solve the problems of raw silk head and tail yarn, winding raw yarn and abnormal yarn that cannot be processed and reused, and achieves convenient implementation, obvious effect and less investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

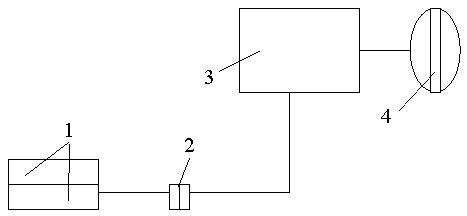

[0021] refer to figure 1 and figure 2 , the invention relates to a process for reprocessing waste filaments in the production process of polyester staple fiber, which is carried out according to the following process steps,

[0022] a). The head and tail yarns, winding raw yarns and abnormal yarns in the production process of polyester staple fiber are made into yarn drums with the same fixed length by using a special guide wire device. The total number of bundled yarn drums is 630~ 6.6 million tex;

[0023] b). After these bundled silk barrels pass through the oil immersion tank, the oil agent is evenly dispersed on the fibers, and the tow becomes lubricated and most of the static electricity is eliminated. Controlled at 0.3~0.35%;

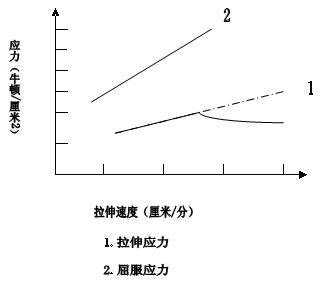

[0024] c). After the tow coming out of the oil immersion tank passes through the first drafting machine, water bath and second drafting machine, the tow is drawn for the first time, and the first section of the tow is drawn in the second draf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com