Electrochemical synthesis method of nickel-phosphorus alloy nanotube array

A nanotube array, nickel-phosphorus alloy technology, applied in nanotechnology and other directions, to achieve the effects of convenient and easy-to-obtain raw materials, simple experimental equipment, and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

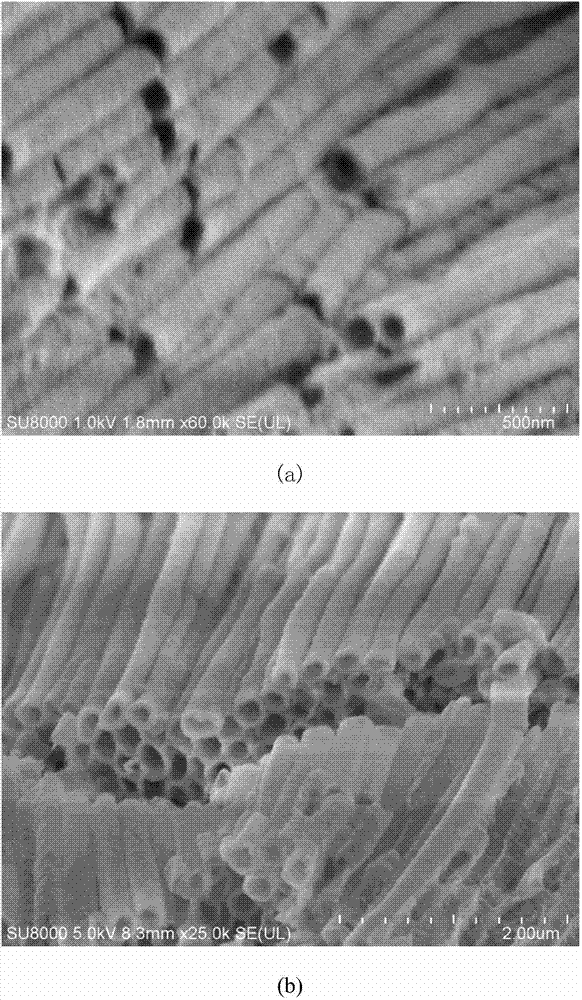

[0023] An electrochemical preparation method of a nickel-phosphorus alloy nanotube array, comprising the following steps:

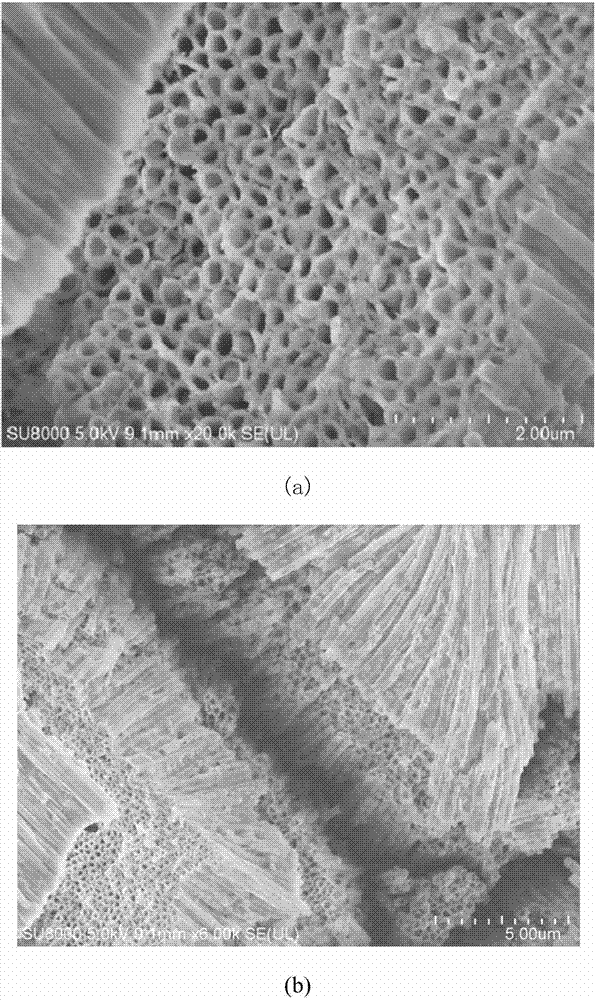

[0024] 1) Pretreatment of the anodized aluminum template and preparation of the gold electrode: the anodized aluminum template was ultrasonically cleaned with absolute ethanol and deionized water for 10 minutes, and dried in the air; a multi-target sputtering system was used on the anodized aluminum template A 10nm gold film is sputtered on the back;

[0025] 2) Preparation of electrolyte: nickel sulfate (NiSO 4 ·6H 2 O), boric acid (H 3 BO 3 ), sodium hypophosphite (NaH 2 PO 2 ·H 2 (0) is raw material, dissolves with deionized water at room temperature, preparation contains each substance concentration and is 100 grams / liter nickel sulfate, 30 grams / liter boric acid, 20 milliliters of aqueous solutions of 70 grams / liter sodium hypophosphite as electrolyte;

[0026] 3) Construction of the electrodeposition reaction circuit: Use double-sided conduct...

Embodiment 2

[0030] An electrochemical preparation method of a nickel-phosphorus alloy nanotube array, comprising the following steps:

[0031] 1) Pretreatment of the anodized aluminum template and preparation of the gold electrode: the anodized aluminum template was ultrasonically cleaned for 15 minutes with absolute ethanol and deionized water, and dried in the air; a multi-target sputtering system was used on the anodized aluminum template A 15nm gold film is sputtered on the back;

[0032] 2) Preparation of electrolyte: nickel sulfate (NiSO 4 ·6H 2 O), boric acid (H 3 BO 3 ), sodium hypophosphite (NaH 2 PO 2 ·H 2 (0) is raw material, dissolves with deionized water at room temperature, preparation contains each substance concentration and is 100 grams / liter nickel sulfate, 30 grams / liter boric acid, 20 milliliters of aqueous solutions of 70 grams / liter sodium hypophosphite as electrolyte;

[0033] 3) Construction of the electrodeposition reaction circuit: Use double-sided conduct...

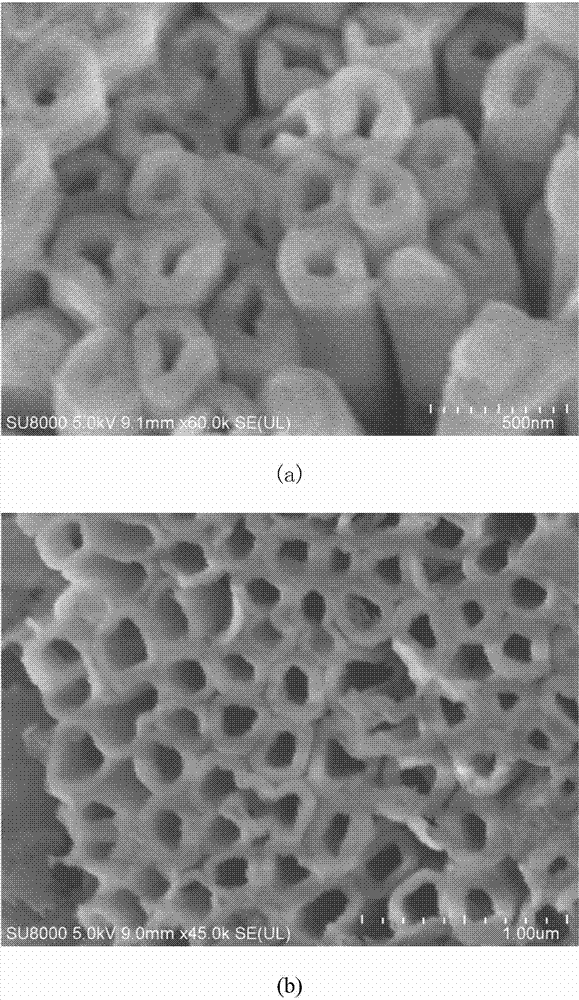

Embodiment 3

[0037] An electrochemical preparation method of a nickel-phosphorus alloy nanotube array, comprising the following steps:

[0038] 1) Pretreatment of the anodized aluminum template and preparation of the gold electrode: the anodized aluminum template was ultrasonically cleaned with absolute ethanol and deionized water for 20 minutes, and dried in the air; a multi-target sputtering system was used on the anodized aluminum template A 20nm gold film is sputtered on the back;

[0039] 2) Preparation of electrolyte: nickel sulfate (NiSO 4 ·6H 2 O), boric acid (H 3 BO 3 ), sodium hypophosphite (NaH 2 PO 2 ·H 2 (0) is raw material, dissolves with deionized water at room temperature, preparation contains each substance concentration and is 50 grams / liter nickel sulfate, 15 grams / liter boric acid, 20 milliliters of aqueous solutions of 35 grams / liter sodium hypophosphite as electrolyte;

[0040] 3) Construction of the electrodeposition reaction circuit: Use double-sided conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com