Method for preparing super-hydrophobic membrane layer on surface of magnesium alloy through one-step method as well as alloy and application of uper-hydrophobic membrane layer

A magnesium alloy, super-hydrophobic technology, applied in the field of magnesium alloy surface treatment and modification, can solve the problems of unsuitability for industrial production, long cycle, complicated operation steps, etc., achieve shortened preparation cycle, simple preparation method, and easy processing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

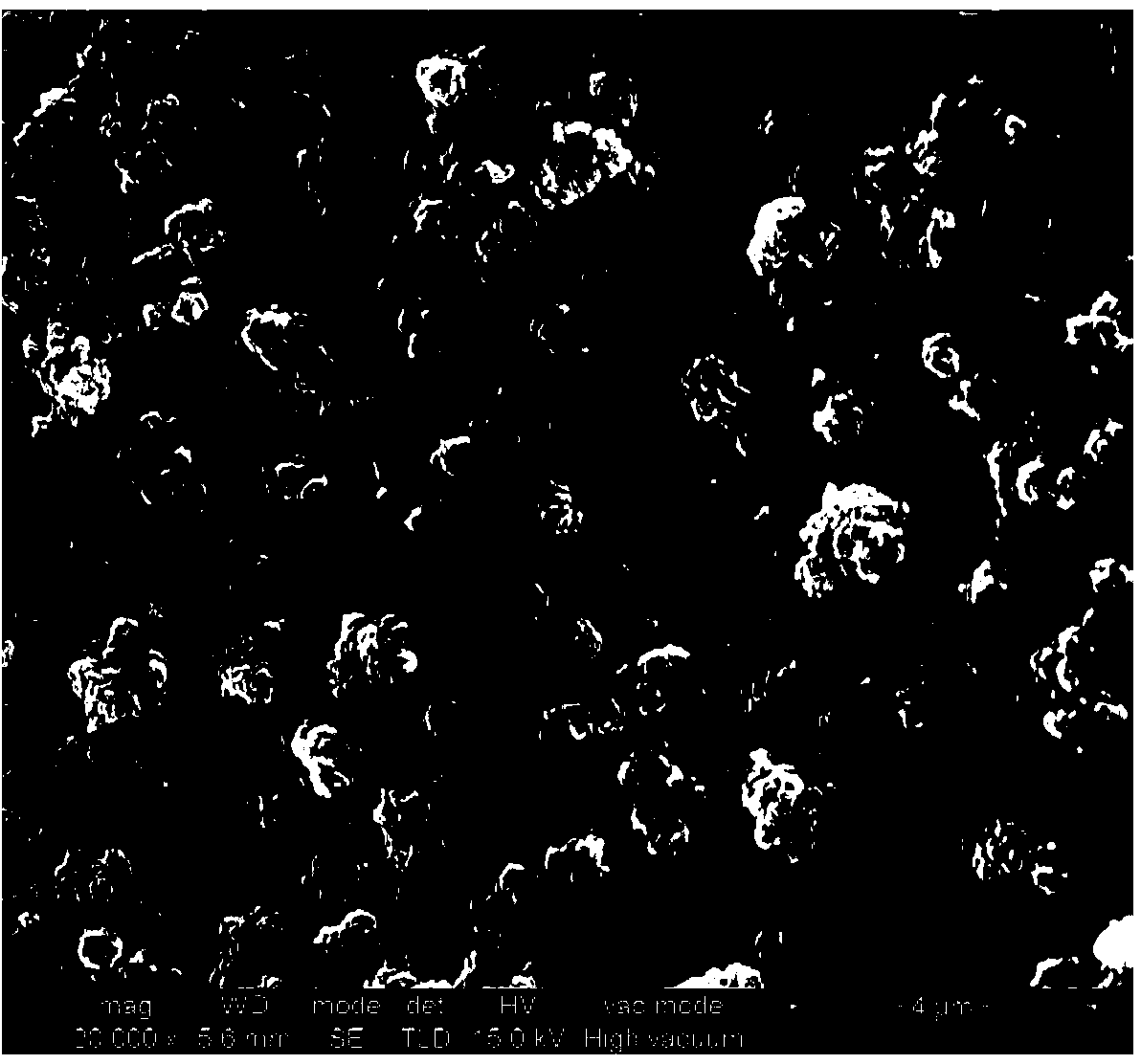

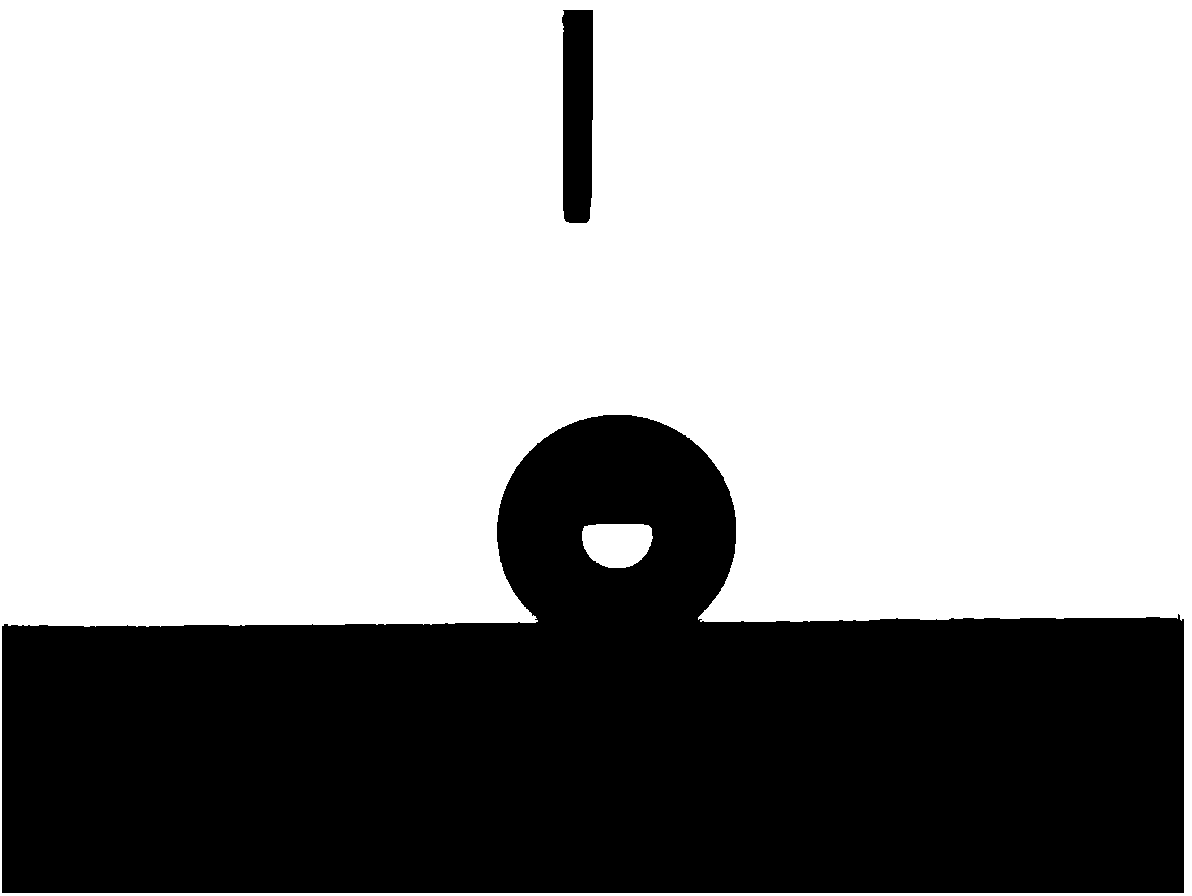

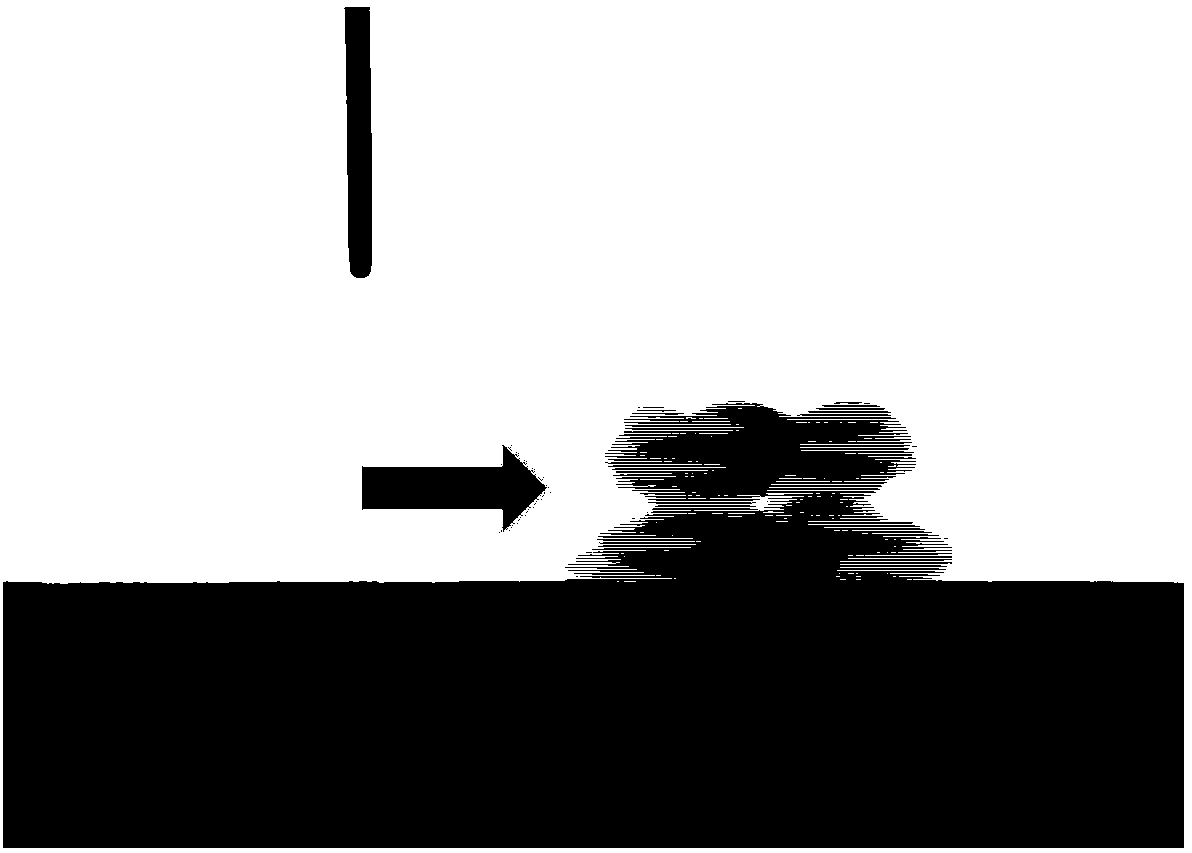

[0029] The ME20 magnesium alloy sheet with a size of 30×20×4 (mm) is subjected to surface pretreatment and electrochemical deposition to obtain a super-hydrophobic surface with outstanding structural features in one step, specifically including the following steps and process conditions:

[0030] Step 1: Magnesium alloy pretreatment

[0031] Sand the surface of the ME20 magnesium alloy plate to 2000#, ultrasonically clean it with acetone at room temperature for 10 minutes, and dry it with cold air;

[0032] Step 2: Plating solution preparation

[0033] Ce(NO 3 ) 3 ·6H 2 O and myristic acid were dissolved in absolute ethanol, where Ce(NO 3 ) 3 ·6H 2 The concentration of O is 0.1mol / L, and the concentration of myristic acid is 0.2mol / L;

[0034] Step 3: Electrodeposition

[0035] With the polished magnesium alloy sample as the cathode and the cleaned platinum plate as the anode, take 100mL of the electroplating solution prepared in step 2, and electrodeposit it for 20min...

Embodiment 2

[0039] The AZ31 magnesium alloy plate with a size of 30×15×5 (mm) is subjected to surface pretreatment and electrochemical deposition to obtain a super-hydrophobic surface with outstanding structural features in one step, specifically including the following steps and process conditions:

[0040] Step 1: Magnesium alloy pretreatment

[0041] Sand the surface of the AZ31 magnesium alloy plate to 2000#, ultrasonically clean it with acetone at room temperature for 10 minutes, and dry it with cold air;

[0042] Step 2: Plating solution preparation

[0043] Ce(NO 3 ) 3 ·6H 2 O and octadecanoic acid were dissolved in absolute ethanol, where Ce(NO 3 ) 3 ·6H 2 The concentration of O is 0.01mol / L, and the concentration of octadecanoic acid is 0.1mol / L;

[0044] Step 3: Electrodeposition

[0045] With the polished magnesium alloy sample as the cathode and the cleaned platinum plate as the anode, take 100mL of the electroplating solution prepared in step 2, and electrodeposit it ...

Embodiment 3

[0049] The ZK60 magnesium alloy sheet with a size of 20×20×3 (mm) is subjected to surface pretreatment and electrochemical deposition to obtain a super-hydrophobic surface with outstanding structural features in one step, specifically including the following steps and process conditions:

[0050] Step 1: Magnesium alloy pretreatment

[0051] Sand the surface of the ZK60 magnesium alloy plate to 2000#, ultrasonically clean it with acetone at room temperature for 10 minutes, and dry it with cold air;

[0052] Step 2: Plating solution preparation

[0053] Ce(NO 3 ) 3 ·6H 2 O and dodecanoic acid were dissolved in absolute ethanol, where Ce(NO 3 ) 3 ·6H 2 The concentration of O is 0.2mol / L, and the concentration of dodecanoic acid is 0.05mol / L;

[0054] Step 3: Electrodeposition

[0055] Take the polished magnesium alloy sample as the cathode, and the cleaned platinum plate as the anode, take 100mL of the electroplating solution prepared in step 2, and electrodeposit it for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com