Plating self-welding method for three-dimensional micro-electrode array

A micro-electrode array and three-dimensional electrode technology, applied in the field of micro-electrode preparation, can solve the problems of expensive and complicated welding instruments, great difficulty, and difficulty in electrical interconnection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

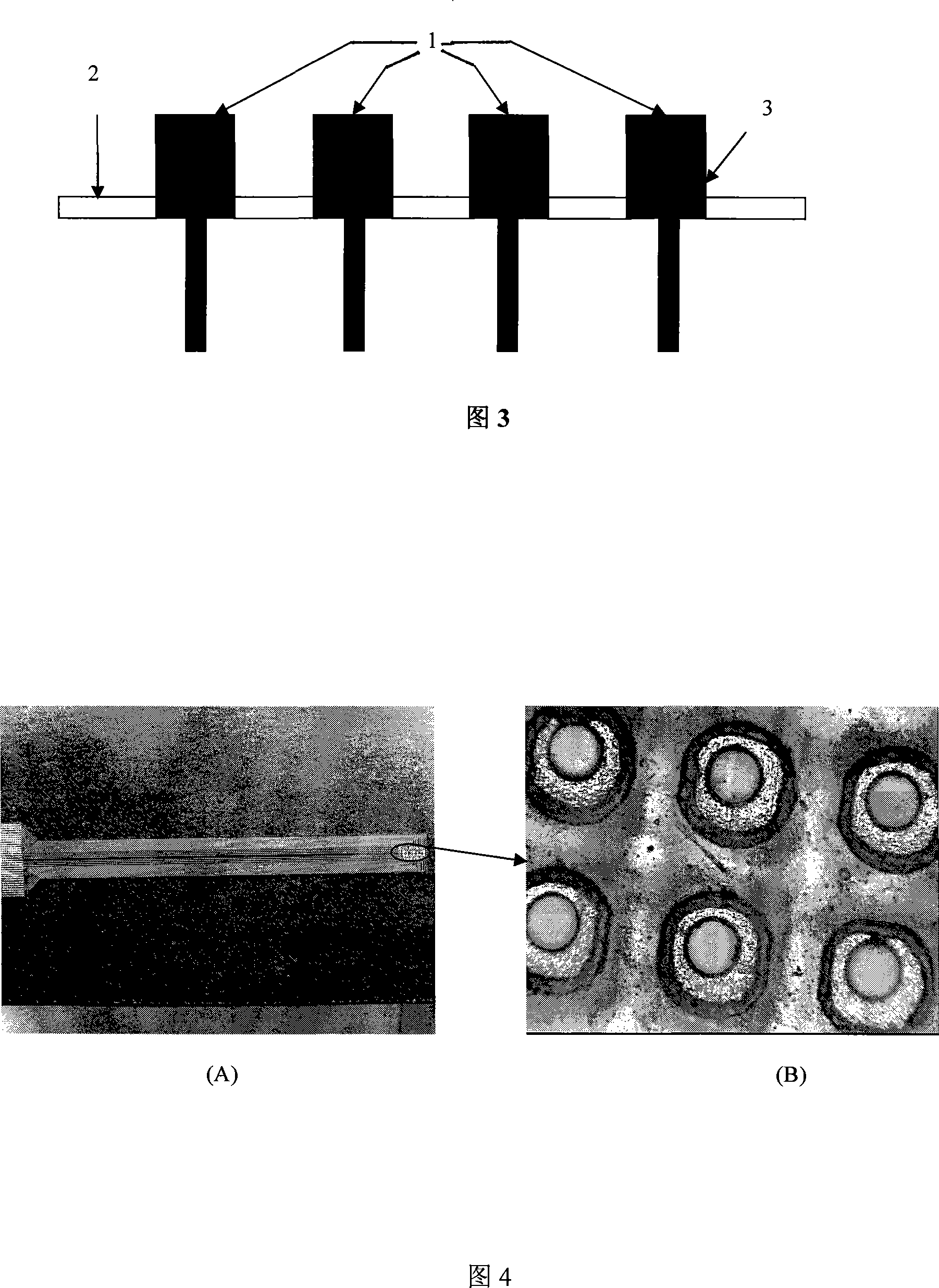

[0014] Weld a microelectrode with a length of 4 mm and a diameter of 0.2 mm in the micro metal hole array of the flexible interconnection shown in Figure 4. The process flow is as follows:

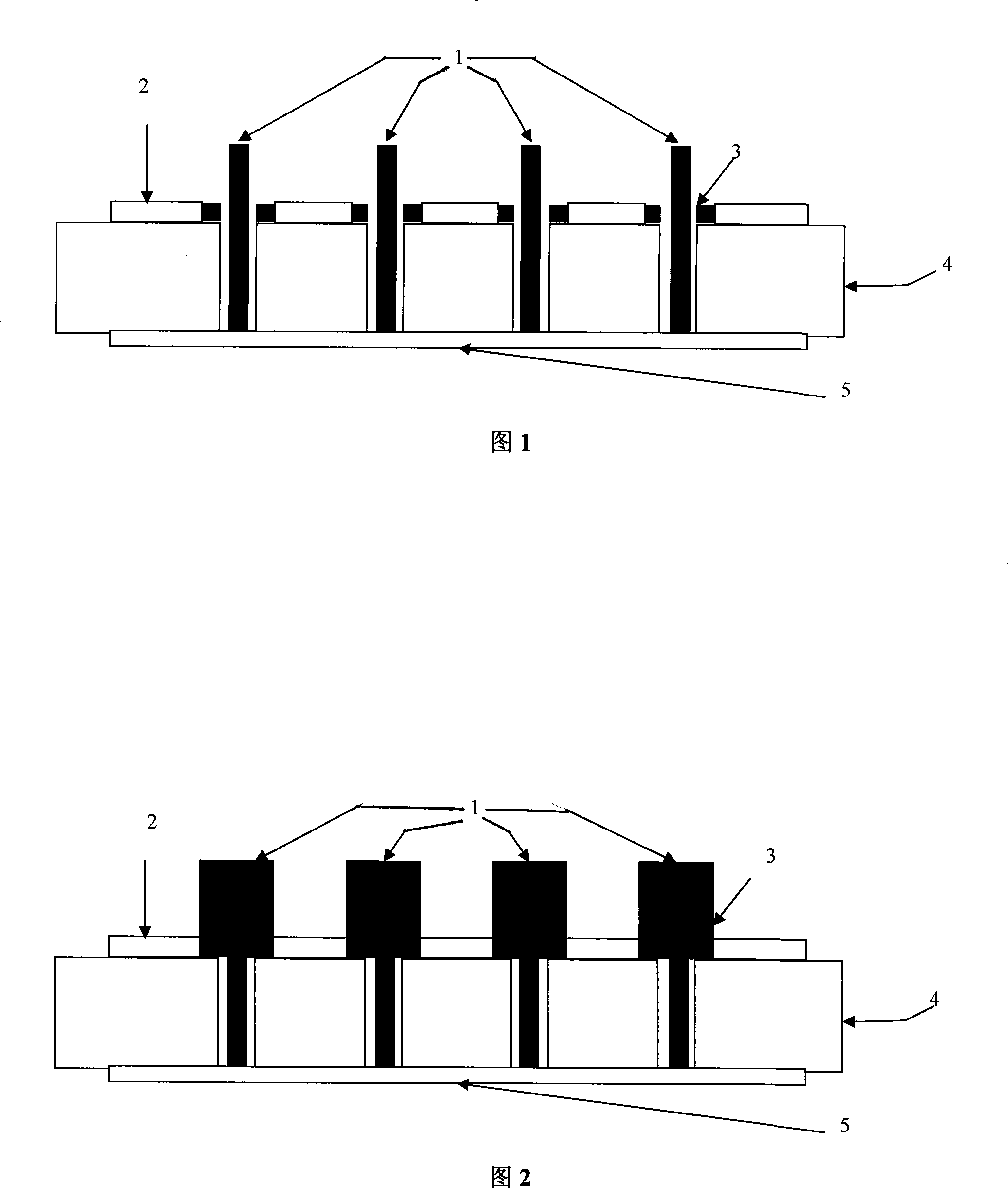

[0015] (a) Fix the part with the metal microhole array in the flexible interconnection line and the microelectrode on the corresponding insulating slot, as shown in Figure 1, the microhole array in the slot corresponds to the micro metal hole in the flexible interconnection line , is a 4×8 array with a diameter of 0.25 μm;

[0016] (b) Apply a layer of silver paste at the interface of the flexible interconnection line to realize the electrical interconnection of all the micro-metal holes, and connect to the cathode of the electroplating power supply to ensure that all the micro-metal holes are electroplated at the same time; fix the slot together with the above The micro-metal hole array of the micro-electrode and the flexible interconnection is partially immersed in the copper electroplat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com