Comb-shaped polycarboxylate as well as synthesis method and application thereof in preparation of dispersing agent

A comb-shaped polycarboxylate, synthesis method technology, applied in application, botanical equipment and method, biocide and other directions, to achieve the effect of low electrical conductivity, meeting performance requirements, good anti-gluing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of synthetic method of comb polycarboxylate, comprises the following steps:

[0036] (1) In terms of parts by mass, 20 parts of styrene, 15 parts of acrylate, 18 parts of acrylic acid and 16 parts of allyl epoxy monomer were added to the reaction kettle protected by nitrogen, and heated to 90 ° C under stirring, Completely dissolve; add 0.7 parts of initiator in batches, stir and react at 90°C for 3 hours; finally add 0.12 parts of chain transfer agent, react at 90°C for 0.3 hours to obtain a copolymer;

[0037] (2) Add 70 parts of amino polyethylene glycol (NH 2 (CH 2 CH 2 O) 20 H), stirring and reacting at 100°C for 2 hours; then cooling down to below 50°C, adding 280 parts of deionized water, stirring evenly, and finally adding 15 parts of ethanolamine to obtain a polycarboxylate liquid product.

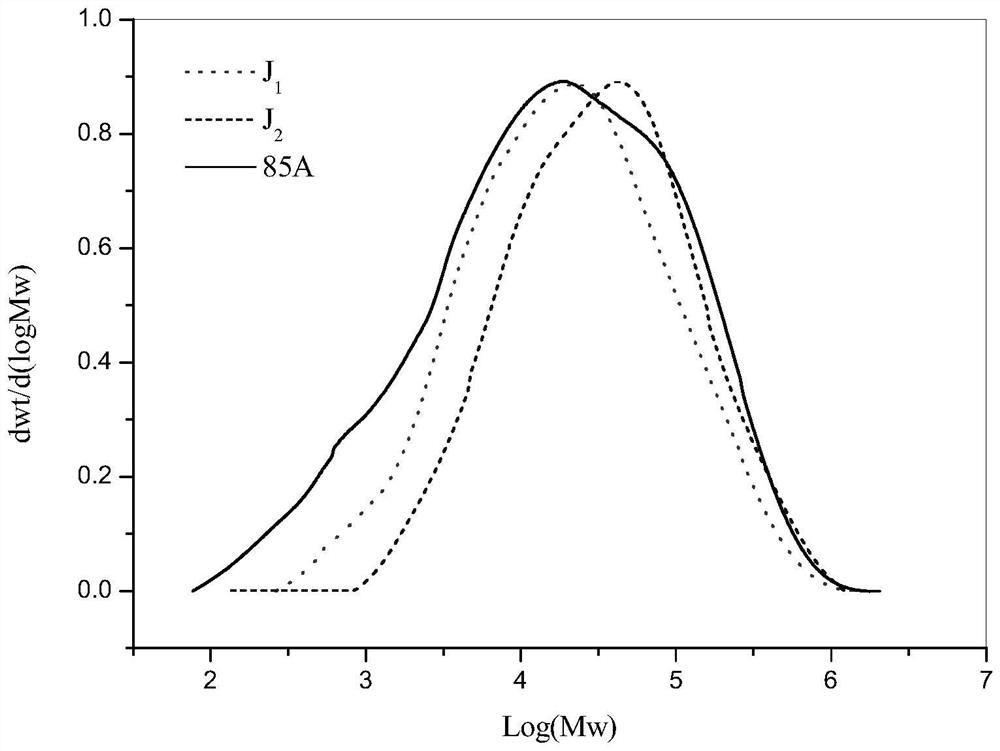

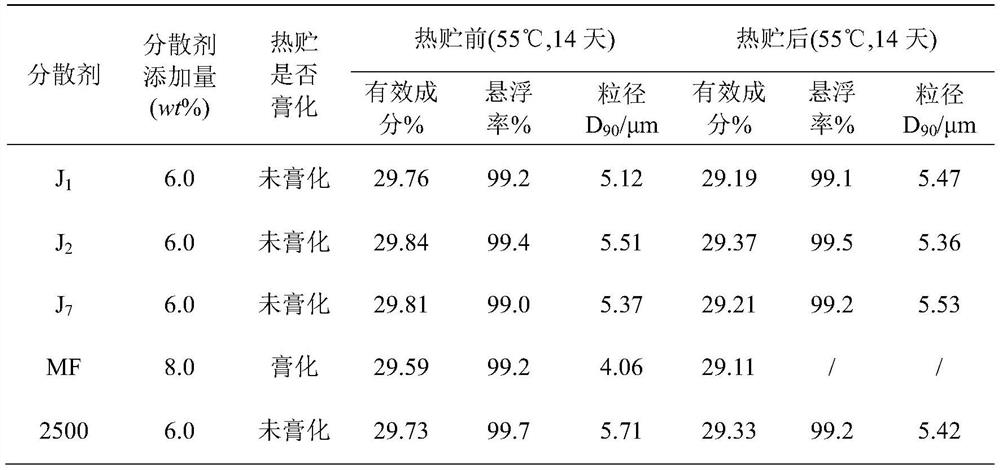

[0038] The comb-shaped polycarboxylate prepared in embodiment 1 is named as J 1 . J in this example 1 The solid content is 35.37%, pH=5-8, and the weight aver...

Embodiment 2

[0040] A kind of synthetic method of comb polycarboxylate, comprises the following steps:

[0041] (1) In terms of parts by mass, 25 parts of styrene, 20 parts of acrylate, 18 parts of methacrylic acid and 16 parts of allyl epoxy monomer are added to the reactor under nitrogen protection, and heated to 85 ℃, completely dissolved; adding 0.9 parts of initiator in batches, stirring and reacting at 85 ℃ for 4 hours; finally adding 0.15 parts of chain transfer agent, reacting at 85 ℃ for 0.5 hours to obtain a copolymer;

[0042] (2) Add 30 parts of amino polyethylene glycol (NH 2 (CH 2 CH 2 O) 15 H) and 60 parts of amino polyethylene glycol (NH 2 (CH 2 CH 2 O) 30 H), stirring and reacting at 95°C for 1.5 hours; then cooling down to below 50°C, adding 320 parts of deionized water, stirring evenly, and finally adding 7 parts of sodium hydroxide to obtain a polycarboxylate liquid product.

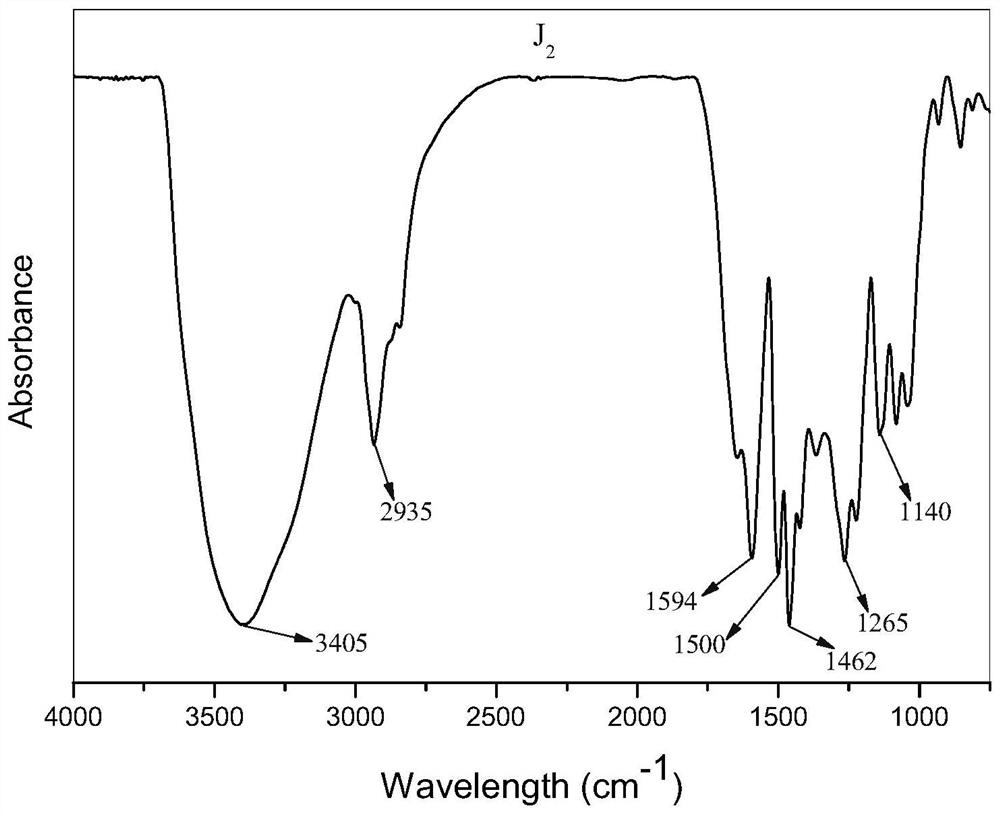

[0043]The comb-shaped polycarboxylate prepared in embodiment 2 is named as J 2 . J i...

Embodiment 3

[0045] A kind of synthetic method of comb polycarboxylate, comprises the following steps:

[0046] (1) In terms of parts by mass, 20 parts of styrene, 25 parts of acrylate, 16 parts of acrylic acid and 12 parts of allyl epoxy monomer are added to the reaction kettle protected by nitrogen, and heated to 70 ° C under stirring, Completely dissolve; add 1 part of initiator in batches, stir and react at 70°C for 3 hours; finally add 0.1 part of chain transfer agent, react at 70°C for 0.3 hours to obtain a copolymer;

[0047] (2) Add 70 amino polyethylene glycol (NH 2 (CH 2 CH 2 O) 30 H), stirring and reacting at 90°C for 1.5 hours; then cooling down to below 50°C, adding 290 parts of deionized water, stirring evenly, and finally adding 12 parts of potassium hydroxide to obtain a polycarboxylate liquid product.

[0048] The comb-shaped polycarboxylate prepared in embodiment 3 is named as J 3 . J in this example 3 The solid content is 35.32%, pH=5-8, and the weight average mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com