Method and apparatus for preparing trichlorosilane through reaction rectification by using proportionate reaction

A technology of trichlorosilane and reactive distillation, which is applied in the field of reactive distillation, can solve the problems of low boiling point of dichlorodihydrosilane, large amount of silicon tetrachloride to be treated, technical blockade, etc., so as to improve the single-pass conversion rate, Improve the utilization rate of raw materials and solve the effect of enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

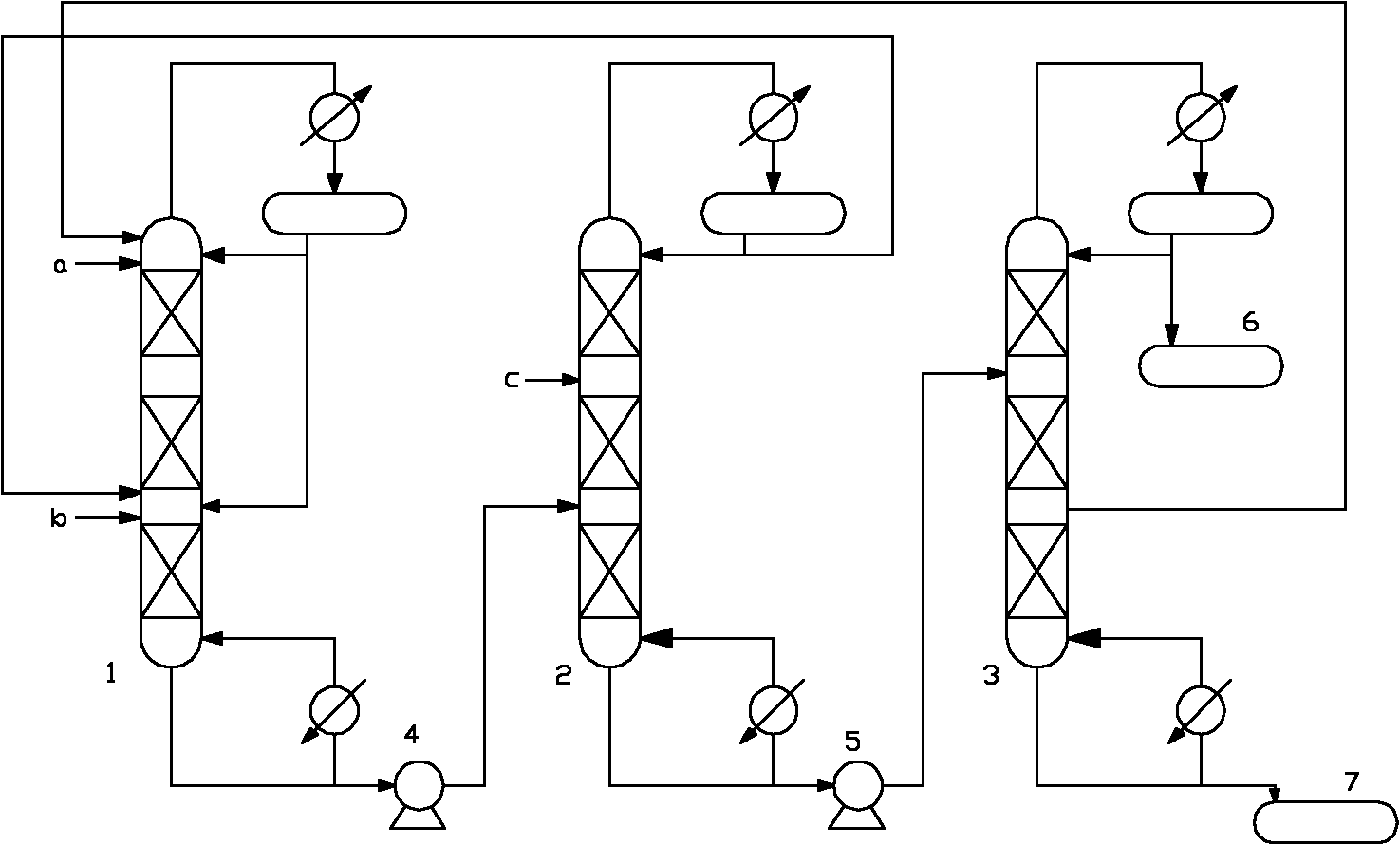

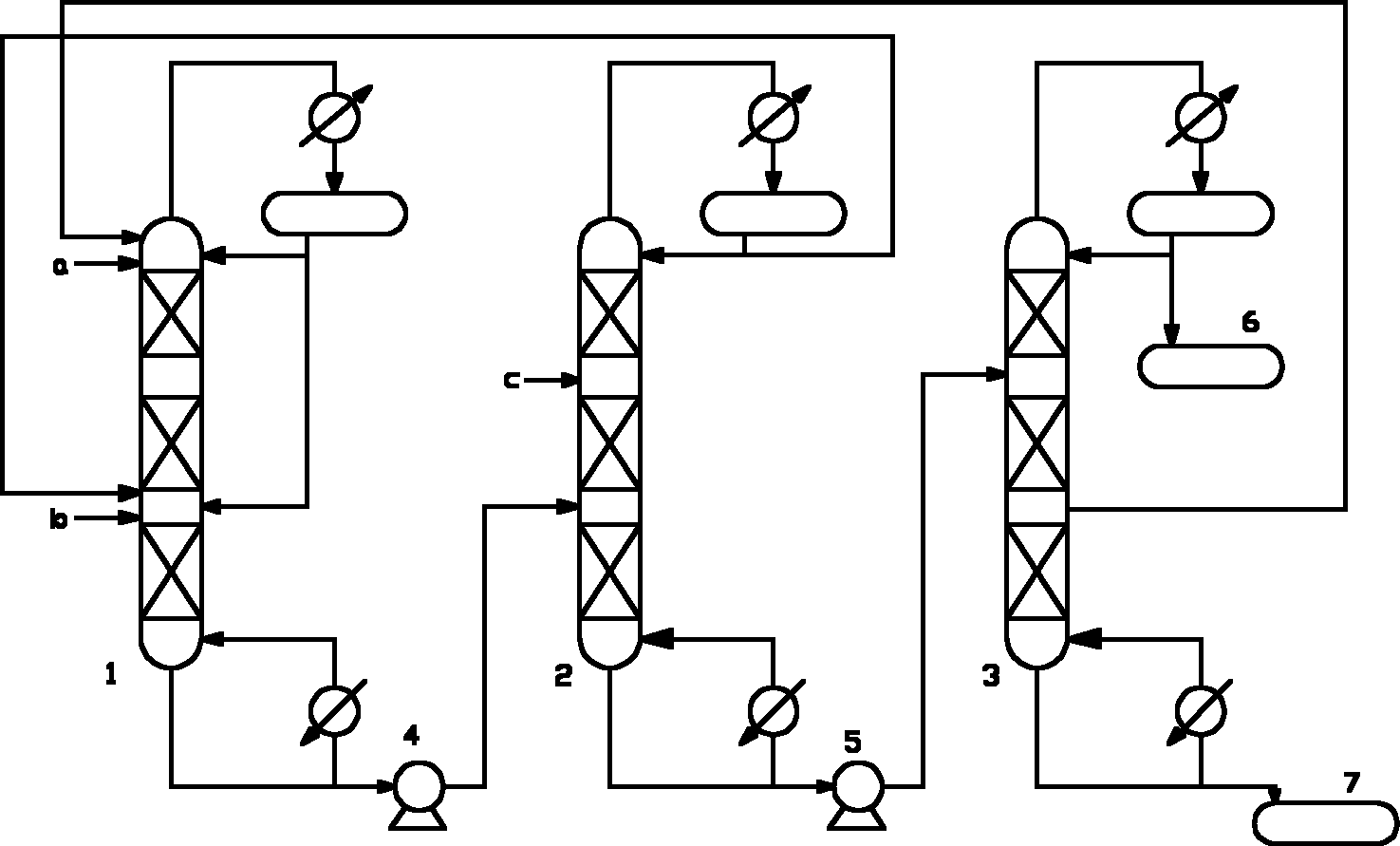

[0022] It is suitable for separate feeding of raw materials: silicon tetrachloride is fed from the liquid phase at position a at the top of reactive distillation tower 1, dichlorodihydrogen silicon is fed from the gas phase or liquid phase at position b at the middle of reactive distillation tower 1, and the reaction is carried out in the reactive distillation tower 1. Carry out in the middle and upper part of distillation tower 1, the dichlorodihydrosilane of incomplete reaction is obtained at the top of the tower, after condensation, a small amount is refluxed from the tower top, and a large amount is returned to the reactive distillation tower 1 from the middle of the tower, and a small amount of dichlorodihydrosilane, The incompletely reacted silicon tetrachloride and the trichlorosilane generated by the reaction are pumped into the middle part of the light removal tower 2 by the feed pump 4 of the light removal tower. The dichlorodihydrogen silicon obtained from the top of...

example 2

[0030] Suitable for mixed feeding of raw materials: the mixed chlorosilane raw material containing dichlorodihydrosilane, trichlorosilane and silicon tetrachloride is fed from the position c in the middle of light removal tower 2, and dichlorodihydrosilane is obtained from the top of the tower, which enters the reaction The middle part of the rectification tower 1 is used as a reactant, and another reactant, silicon tetrachloride, is withdrawn from the side line of the lower part of the weight removal tower 3 and enters the top of the reactive rectification tower 1 . Incompletely reacted dichlorodihydrosilane is obtained from the top of reactive distillation tower 1. After condensation, a small amount is refluxed from the top of the tower, and a large amount is returned to reactive distillation tower 1 from the middle of the tower. A small amount of dichlorodihydrosilane, incompletely The reacted silicon tetrachloride and the trichlorosilane generated by the reaction are fed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com