Furnace end beam structure for steel rolling heating furnace

A furnace head beam and heating furnace technology, which is applied to heat treatment furnaces, furnaces, furnace types, etc., can solve problems such as the deflection of the furnace head beam, heavy refractory material weight, and reduced cooling strength of the furnace head beam, so as to reduce the amount of construction and The construction period, meet the production process requirements, and facilitate the effect of spot inspection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

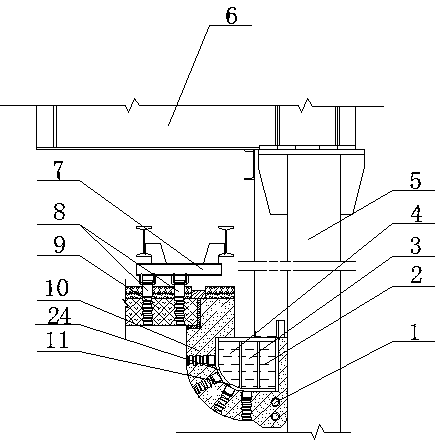

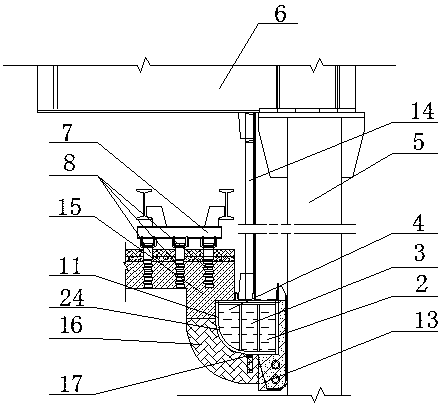

[0021] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner in conjunction with the accompanying drawings.

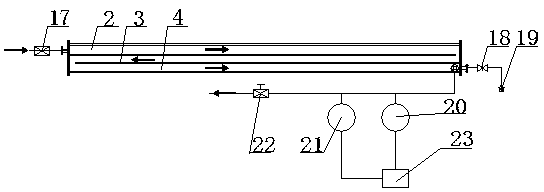

[0022] by attaching figure 1 and attached figure 2 It can be seen that a furnace head beam structure of a steel rolling heating furnace includes a furnace head beam steel structure 24, and the furnace head beam steel structure 24 is connected with the furnace top beam 6 through the furnace head beam hanging 14. There are circulating cooling pipes in the furnace head beam steel structure 24. The cooling pipe includes an inlet cooling pipe 2, an outlet cooling pipe 4 and a return cooling pipe 3 located between the inlet cooling pipe 2 and the outlet cooling pipe 4, and the return cooling pipe 3 is respectively connected with the inlet cooling pipe 2 and the outlet cooling pipe 3. The pipe 4 is connected; the sewage device 18, the flow monitoring device 21 and the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com