Light unit-built type thermal insulation roof board and technological process thereof

A thermal insulation roof panel and assembled technology, which is applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve problems such as thermal insulation, poor sound insulation, difficult handling of detailed nodes, and high environmental and climate requirements. The effect of fewer processes, convenient pipeline layout, and simplified construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing the implementation of the present invention is described in detail:

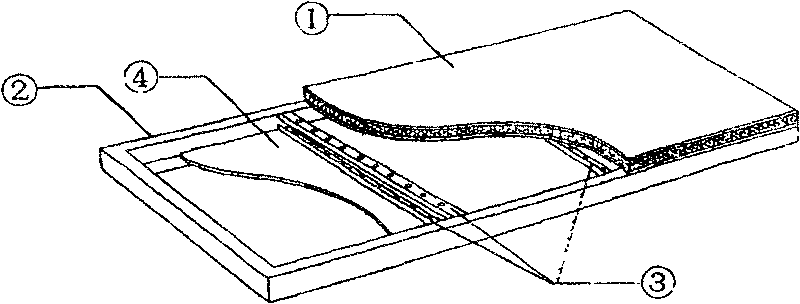

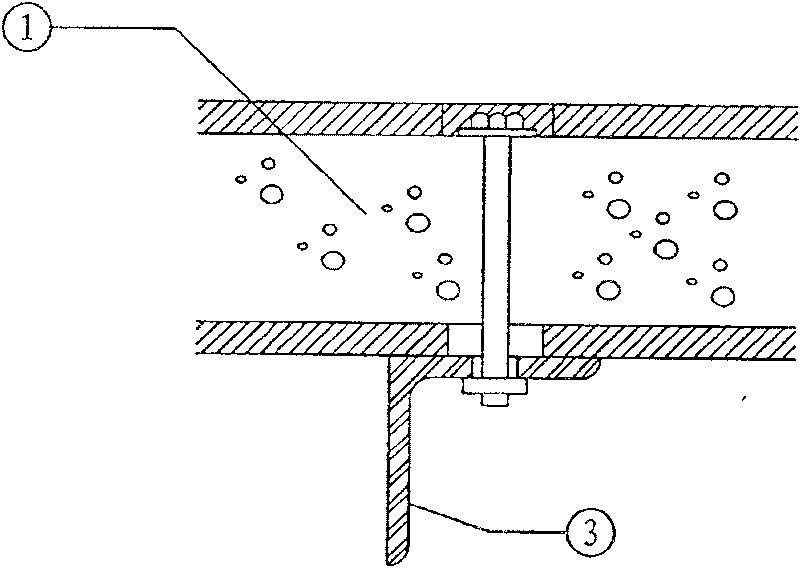

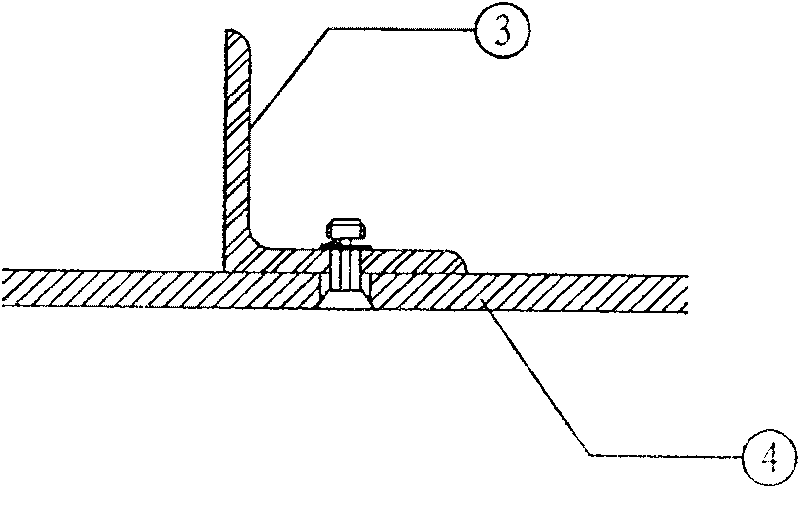

[0020] A composite load-bearing thermal insulation surface layer (1) is manufactured, and two inorganic surface layers are respectively reinforced with reinforcing fibers or steel mesh. The assembled profiled steel channel (2) and the center line of the span direction of the roof panel and the equidistant parts of the two ends of the center line are connected (3) as a load-bearing steel frame structure of the light assembled thermal insulation roof panel. Connecting holes and elliptical connecting holes are provided on the upper surface of the profiled steel channel (2) and the surface of the connecting piece (3) at the center line in the span direction and at equidistant positions at both ends of the center line. Bolts are used to connect the composite load-bearing thermal insulation surface layer (1), the profiled steel channel (2) and the connecting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com