A method of electrochemical oxidation degradation mineral surface flotation agent

A flotation agent and oxidative degradation technology, applied in the field of electrochemical oxidation degradation of mineral surface flotation agent, mineral surface flotation agent removal field, can solve very few problems, achieve reduced power loss, high degradation efficiency, select good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

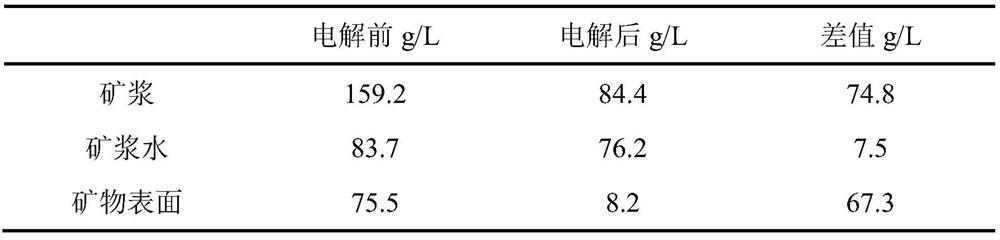

[0033]Huangshaping polymetallic concentrator adopts the process of flotation sulfide ore first, and then oxidized ore. A large amount of xanthate remains in the tailings of sulfur separation (that is, raw tungsten ore), which makes the tungsten separation section foam too much and merge. Poor sex. Electrolytic oxidation is used to degrade the surface of sulfur separation tailings, the electrode is graphite electrode, the current is 300mA, and the electrolyte is 200g / L Na 2 SO 4 , with the use of 0.05mol / L hydrochloric acid, the electrolysis time is 0.5 hours. The COD values before and after electrolysis are shown below. The removal rate of organic matter on the mineral surface can reach 89.14%, which shows that the selectivity and efficiency of this method are very high.

[0034]

Embodiment 2

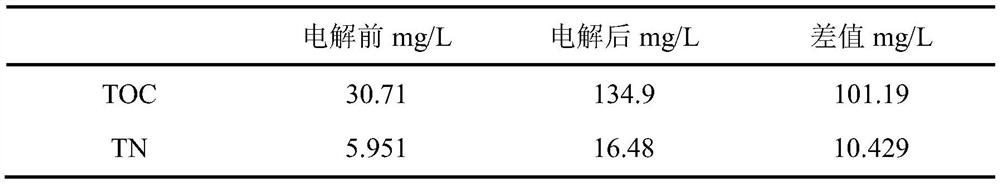

[0036] The flotation tungsten concentrate of Shizhuyuan Dongbo Concentrator in Chenzhou, Hunan Province contains a large amount of organic chemicals, mainly benzohydroxamic acid, which affects the filtration and packaging process of its products. Graphite electrode is selected, the applied current is 1000mA, the concentration of electrolyte NaCl is 50g / L, 0.001mol / L hydrochloric acid, and the electrolysis time is 1 hour. The electrolysis test is carried out on the flotation concentrate. The changes of total organic carbon and total nitrogen in the solution are as follows. In the electrolysis process, distilled water is used to make the concentrate into pulp in advance, and the organic matter on the mineral surface is desorbed from the mineral surface and enters the solution, which can effectively realize the removal of the mineral surface agent.

[0037]

Embodiment 3

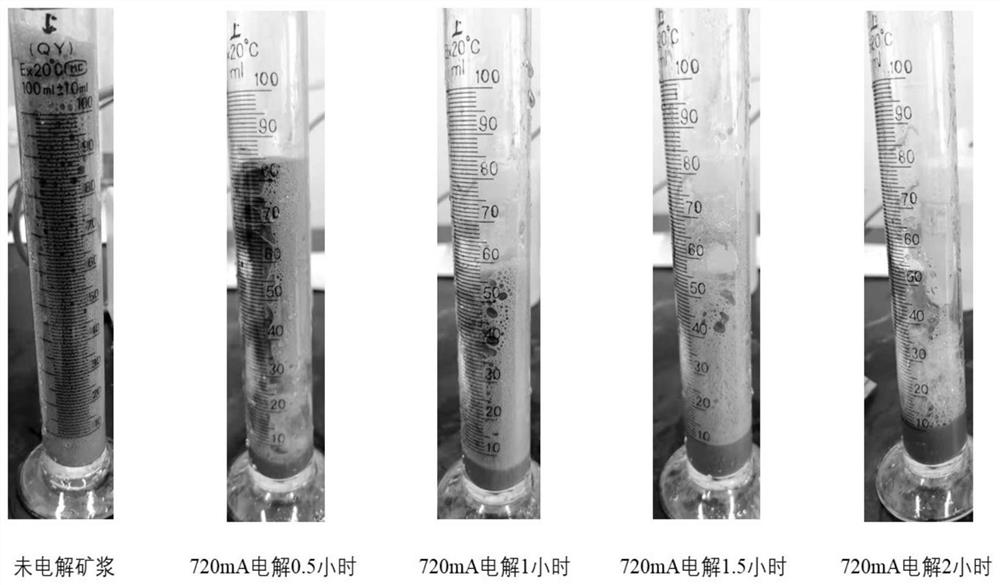

[0039] In order to solve the problem of foam overflow caused by the agent adsorbed on the mineral surface in the combination process of persimmon and bamboo garden for metallurgical acid method pretreatment, graphite electrodes are selected, the applied current is 720mA, the concentration of electrolyte NaCl is 50g / L, and 0.01mol / L hydrochloric acid , for the flotation of tungsten concentrate pulp in the combination of dressing and smelting, the electro-oxidative drug removal test was carried out, and the results are as follows figure 1 shown. It can be seen that with the increase of electrolysis time, the foam layer formed by acid bubble pretreatment becomes thinner, the foam distribution becomes looser and the viscosity decreases significantly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com