Preparation method for SiBN(C) ceramic fiber precursor

A ceramic fiber and precursor technology, which is applied in the field of preparation of ceramic fiber materials, can solve problems such as constraints, and achieve the effect of simple operation and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

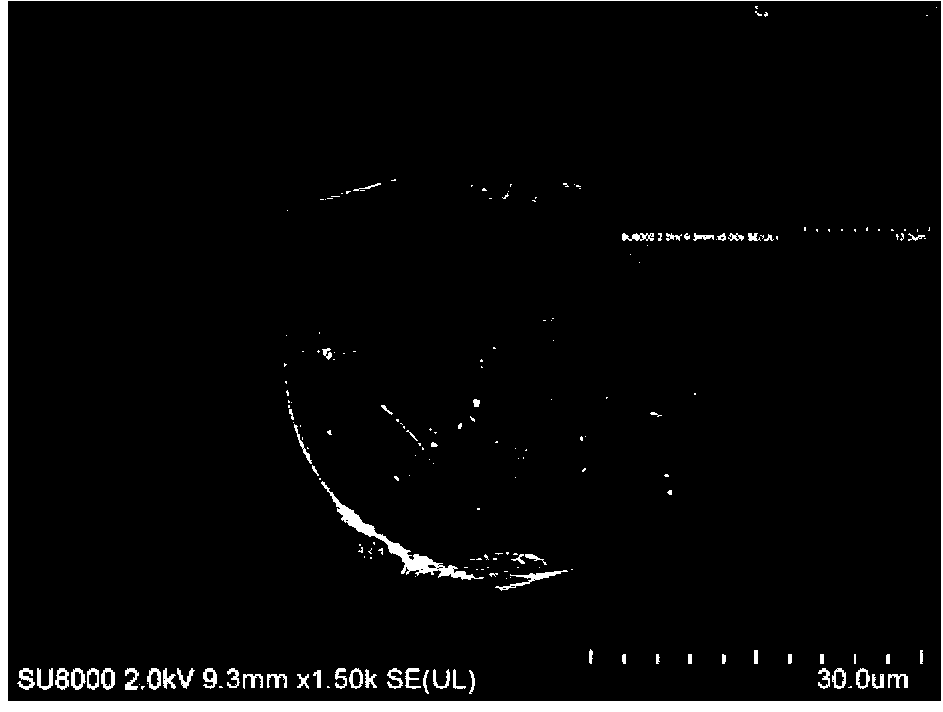

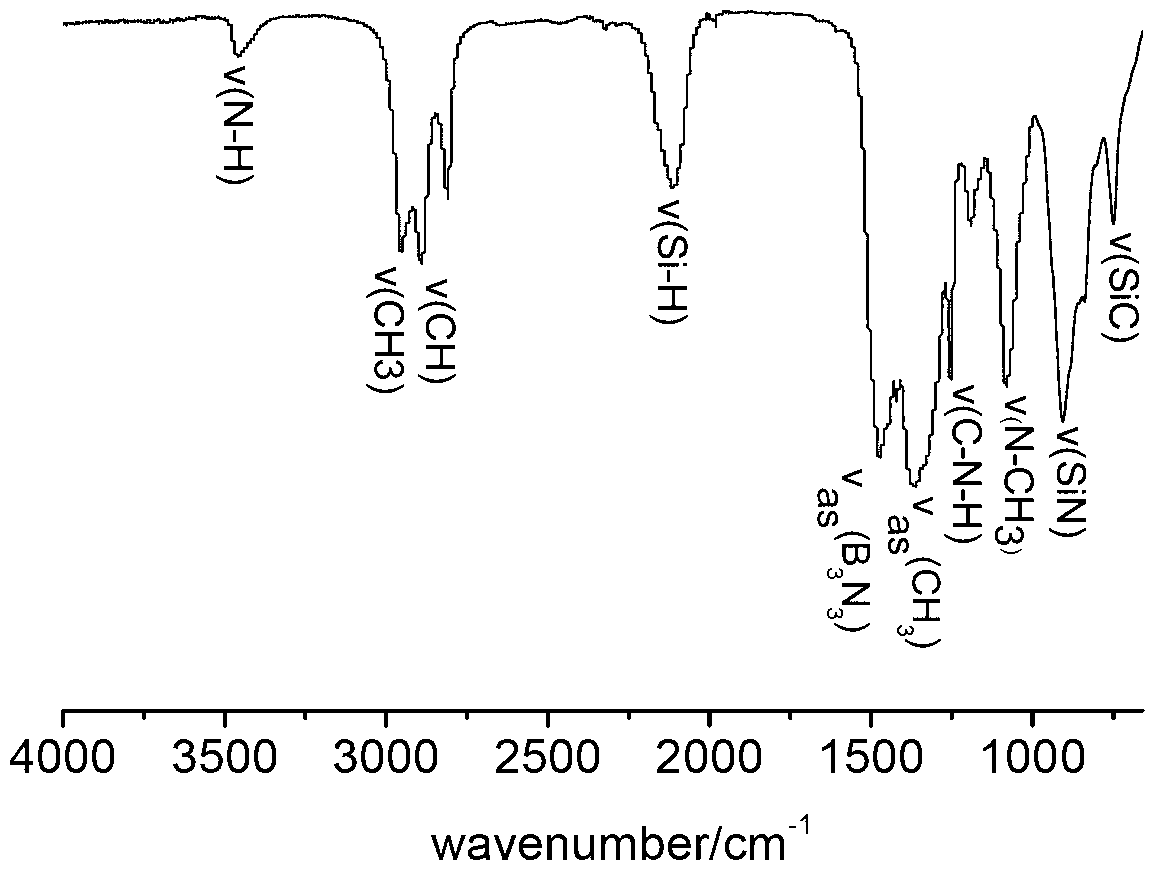

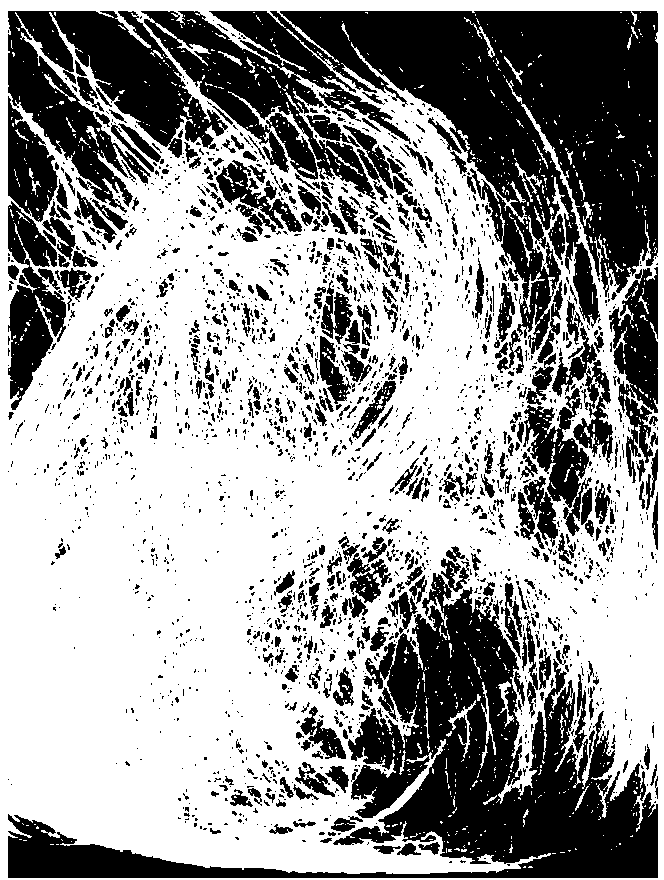

[0028] (1) Put the anhydrous toluene solution of the precursor molecules in a reaction vessel with a stirring and distillation device, heat to 120°C to remove the toluene solvent, and after the solvent is distilled, heat up to 150°C for pre-polymerization to a certain degree of polymerization , with an average molecular weight of 600; (2) Add 6% hydroxyl-terminated polydimethylsiloxane (molecular weight about 500) to the reaction system, and polymerize at 160°C for 40 hours to obtain a copolymerized modified polysiloxane Boron nitrogen precursor polymer; (3) Put the polysilicon boron nitrogen precursor polymer in the melt spinning equipment for vacuum defoaming for 4 hours, under the conditions of temperature 130 ℃, pressure 5 MPa, winding speed 450m / min A SiBN(C) ceramic fiber precursor with a diameter of 20 μm was prepared by melt spinning, and the precursor had good flexibility.

Embodiment 2

[0030] (1) Put the toluene solution of the precursor molecules in a reaction vessel with a stirring and distillation device, heat to 130°C to remove the toluene solvent, and after the solvent is distilled, raise the temperature to 140°C for pre-polymerization to a certain degree of polymerization, The average molecular weight is 2300;

[0031] (2) Add bis(3-aminopropyl) end-capped polydimethylsiloxane (molecular weight about 2500) with a mass fraction of 3% to the reaction system, and polymerize at 180°C for 30 hours to obtain a copolymerized modified polydimethylsiloxane. Silicon boron nitrogen precursor polymer; (3) Put the polysilicon boron nitrogen precursor polymer in the melt spinning equipment for vacuum degassing for 6 hours, under the conditions of temperature 125 ℃, pressure 8MPa, winding speed 250m / min A SiBN (C) ceramic fiber precursor with a diameter of 27 μm was prepared by melt spinning under the lower pressure, and the precursor had good flexibility.

Embodiment 3

[0033](1) Put the toluene solution of the precursor molecules in a reaction vessel with a stirring and distillation device, heat to 125°C to remove the toluene solvent, and after the solvent is distilled, raise the temperature to 130°C for pre-polymerization to a certain degree of polymerization; (2) Add hexamethylenediamine with a mass fraction of 1% to the reaction system, and polymerize at 170°C for 32 hours to obtain a copolymerized modified polysilicon boron nitrogen precursor polymer; (3) polymerize the polysilicon boron nitrogen precursor The material was placed in a melt spinning equipment for vacuum defoaming for 5 hours, and the SiBN (C) ceramic fiber precursor with a diameter of 35 μm was obtained by melt spinning under the conditions of a temperature of 135 ° C, a pressure of 9 MPa, and a winding speed of 175 m / min. The precursor has good flexibility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com