Method of preparing dimethyl dichloro silicane using organic silicon high boiling point substance

A technology of dimethyldichlorosilane and methylchlorosilane, which is applied in the field of preparing dimethyldichlorosilane by using organosilicon high boilers, can solve the problems of certain difficulty in industrialization, high reactor cost, and high reaction temperature. Achieve the effect of outstanding technical indicators, simple process and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

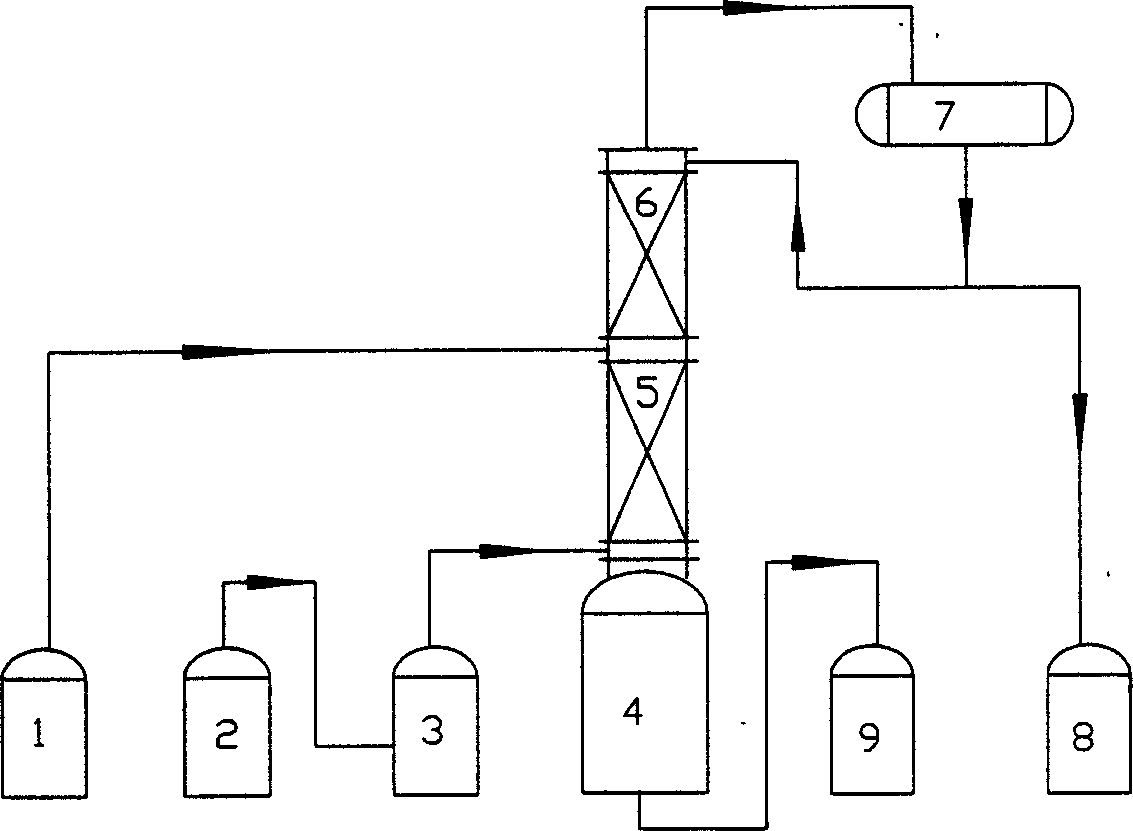

Image

Examples

Embodiment 1

[0054] High boilers (see table for composition) are added to the tower still type cracking reactor at a speed of 40g / h, the hydrogen chloride feed rate is 75ml / min, and the tri-n-butylamine consumption in the gas preheater is the total amount of high boiler monomers 1%, the reaction temperature is 125-130°C, the temperature in the rectification section is 140±2°C, the temperature in the stripping section is 85°C, and it operates under normal pressure. The top product is 43-47g / h, the reaction is carried out for 50h, and the conversion rate is 91.62%. The composition of the lysate is shown in Table 3.

[0055] Table 3 Product Gas Chromatography Analysis

[0056] MeHSiCl 2 MeSiCl 3 Me 2 SiCl 2

[0057] 1~10h 38.18 16.05 42.71

[0058] 11~20h 44.59 20.26 32.66

[0059] 21~30h 43.97 21.20 29.87

[0060] 31~40h 39.00 16.85 41.30

[0061] 41~50h 26.59 26.85 43.45

[0062] 1~50h 39.79 21.03 36.93

Embodiment 2

[0064] The reaction process is the same as in Example 1, the amount of tri-n-butylamine is 1.5% of the total amount of high boiler monomers, the overhead product is 45-48g / h, the reaction is carried out for 50h, and the conversion rate is 92.9%. The composition of the cleavage product is shown in Table 4.

[0065] Table 4 Product Gas Chromatography Analysis

[0066] Reaction time MeHSiCl 2 MeSiCl 3 Me 2 SiCl 2

[0067] 1~10h 38.66 7.84 48.78

[0068] 11~20h 32.56 7.54 56.43

[0069] 21~30h 31.19 27.34 38.43

[0070] 31~40h 19.24 31.11 45.71

[0071] 41~50h 15.66 40.61 40.32

[0072] 1~50h 29.44 20.32 46.41

Embodiment 3

[0074] The reaction process is the same as in Example 2, using methyl chloride as a catalyst, the overhead product is 28-32g / h, the reaction is carried out for 50h, and the conversion rate is 70.47%. The composition of the cleavage product is shown in Table 5.

[0075] Table 5 Product Gas Chromatography Analysis

[0076] Reaction time MeCl 3 MeSiCl 3 Me 2 SiCl 2 high boiler

[0077] 1~10h 5.39 25.31 56.42 11.18

[0078] 11~20h 6.20 34.69 49.93 8.39

[0079] 21~30h 6.02 31.26 54.38 10.28

[0080] 31~40h 5.48 28.79 47.61 9.97

[0081] 41~50h 6.51 29.98 53.19 11.06

[0082] 1~50h 5.78 30.06 52.68 10.01

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com