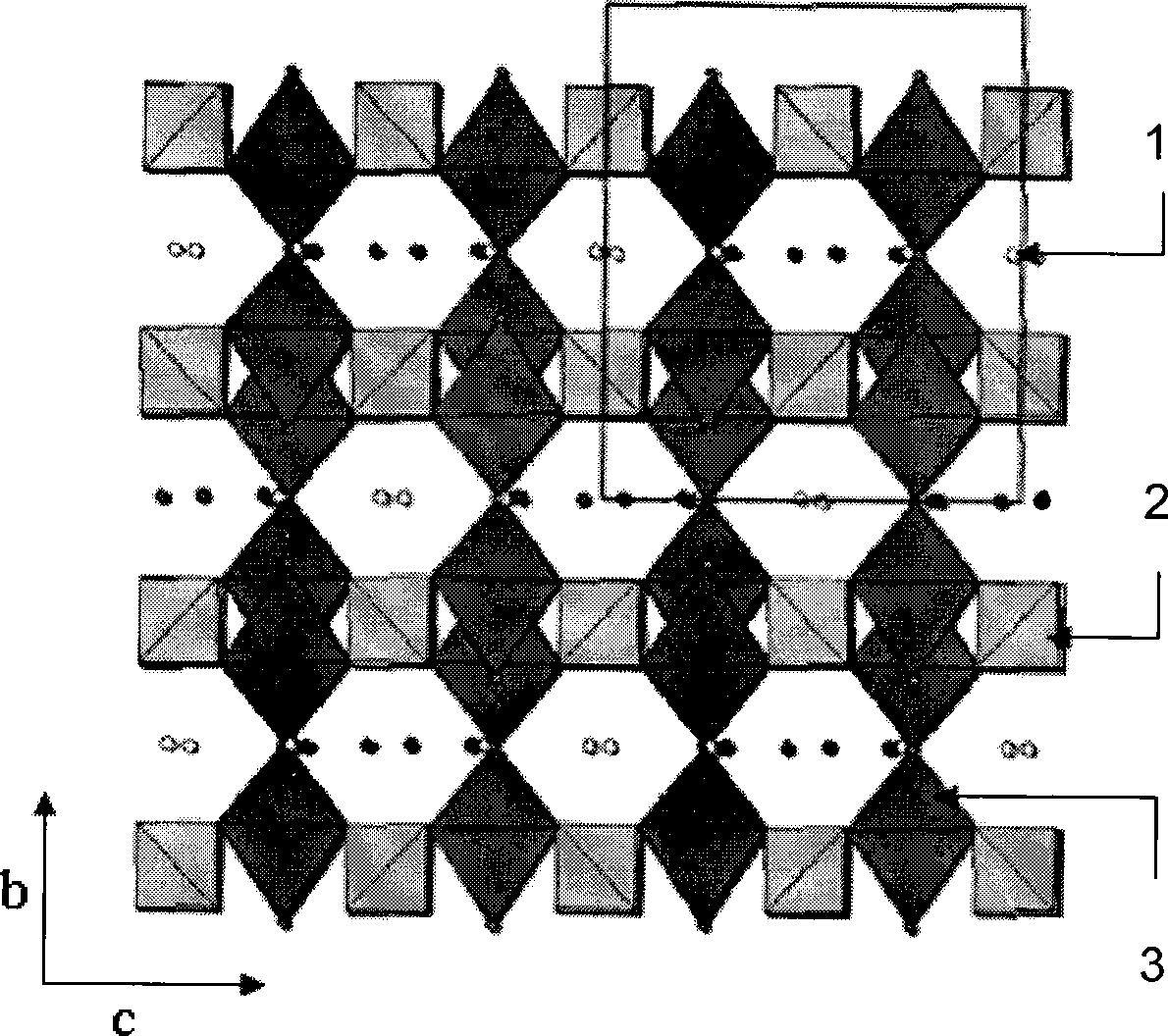

Sodium-base lithium ion secondary battery anode material and method of manufacturing the same

A secondary battery and positive electrode material technology, applied in the direction of battery electrodes, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

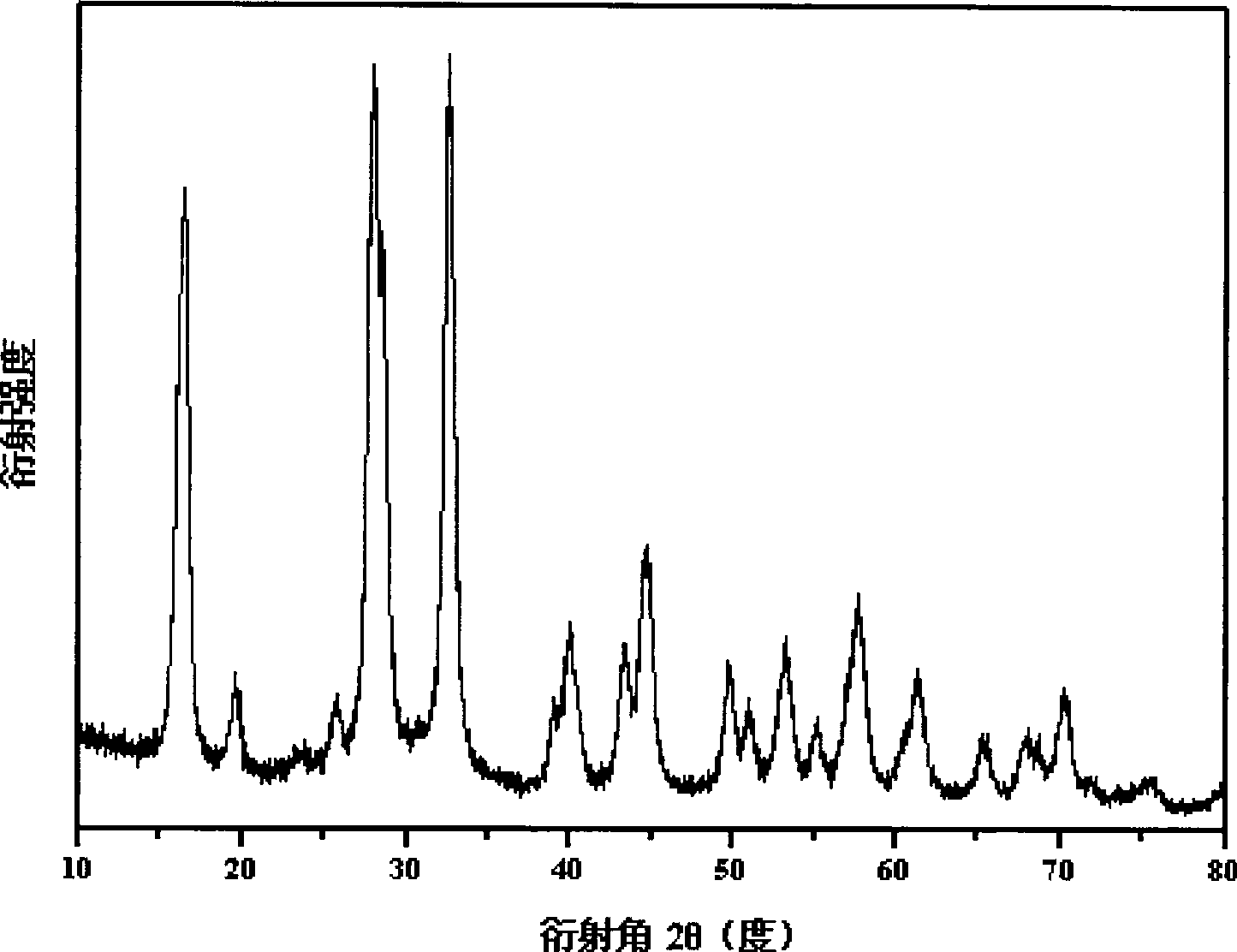

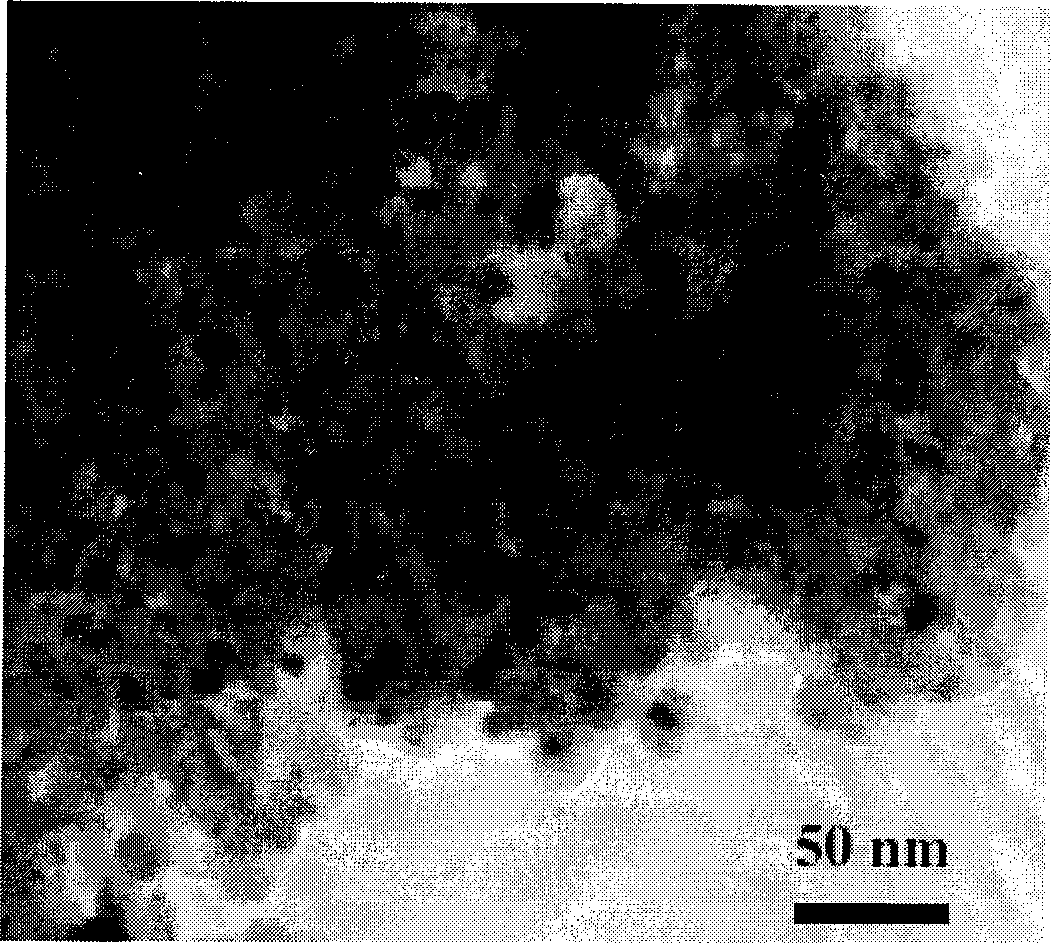

Examples

Embodiment 1

[0020] The sources of the reaction raw materials are as follows: sodium fluoride (NaF), produced from Tianjin No. 3 Chemical Reagent Factory, ammonium metavanadate (NH4 VO 3 ), produced by China Pharmaceutical Group Shanghai Chemical Reagent Company; ammonium hydrogen phosphate (NH 4 h 2 PO 4 ), produced from Tianjin Damao Chemical Reagent Factory; citric acid (C 6 h 8 o 7 ·H 2 O), produced in Beijing Chemical Plant.

[0021] Select the above NaF, NH 4 VO 3 , NH4H 2 PO 4 and citric acid as raw reagents. NaF, NH 4 VO 3 , and NH4H 2 PO 4 The molar dosage is 0.015mol, 0.010mol, 0.010mol respectively, corresponding to Na + :V 5+ :PO 4 3- :F - The molar ratio is 3:2:2:3.

[0022] Add the above raw materials to 120ml of distilled water, and at a constant temperature of 80°C, add 2.10g of citric acid (equivalent to a molar ratio of citric acid to ammonium metavanadate of 0.8:1) while stirring, and stir until a paste gel forms. acid complex.

[0023] Put the citr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com