Reactive distillation device for preparing trichlorosilane from mixed chlorosilane and method for device

A technology of trichlorosilane and chlorosilane, which is applied in the field of reaction rectification devices for preparing trichlorosilane by mixing chlorosilanes, can solve problems such as unreasonable energy utilization, and achieves the solution of by-product enrichment, saving equipment investment, and simplifying process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

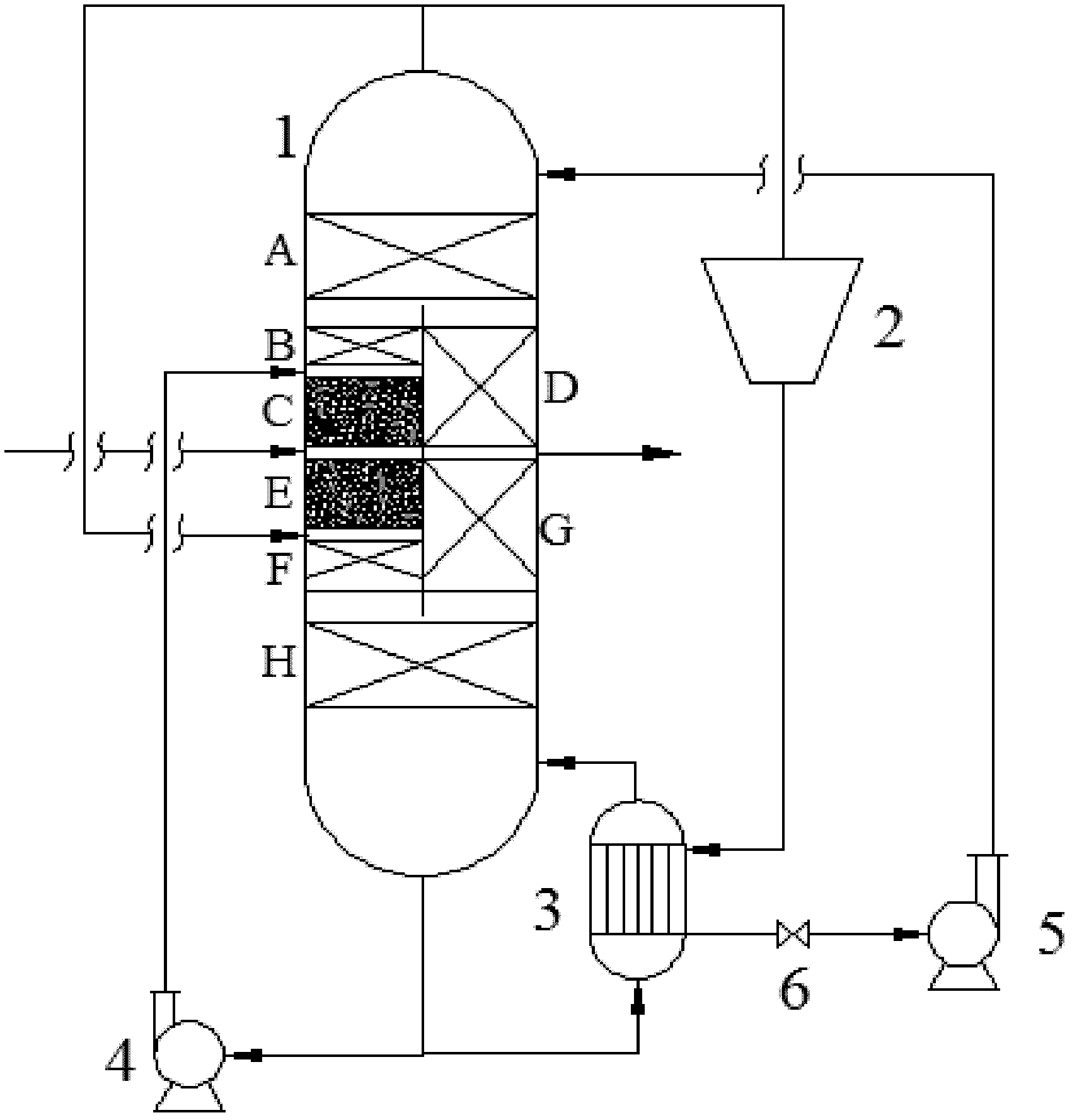

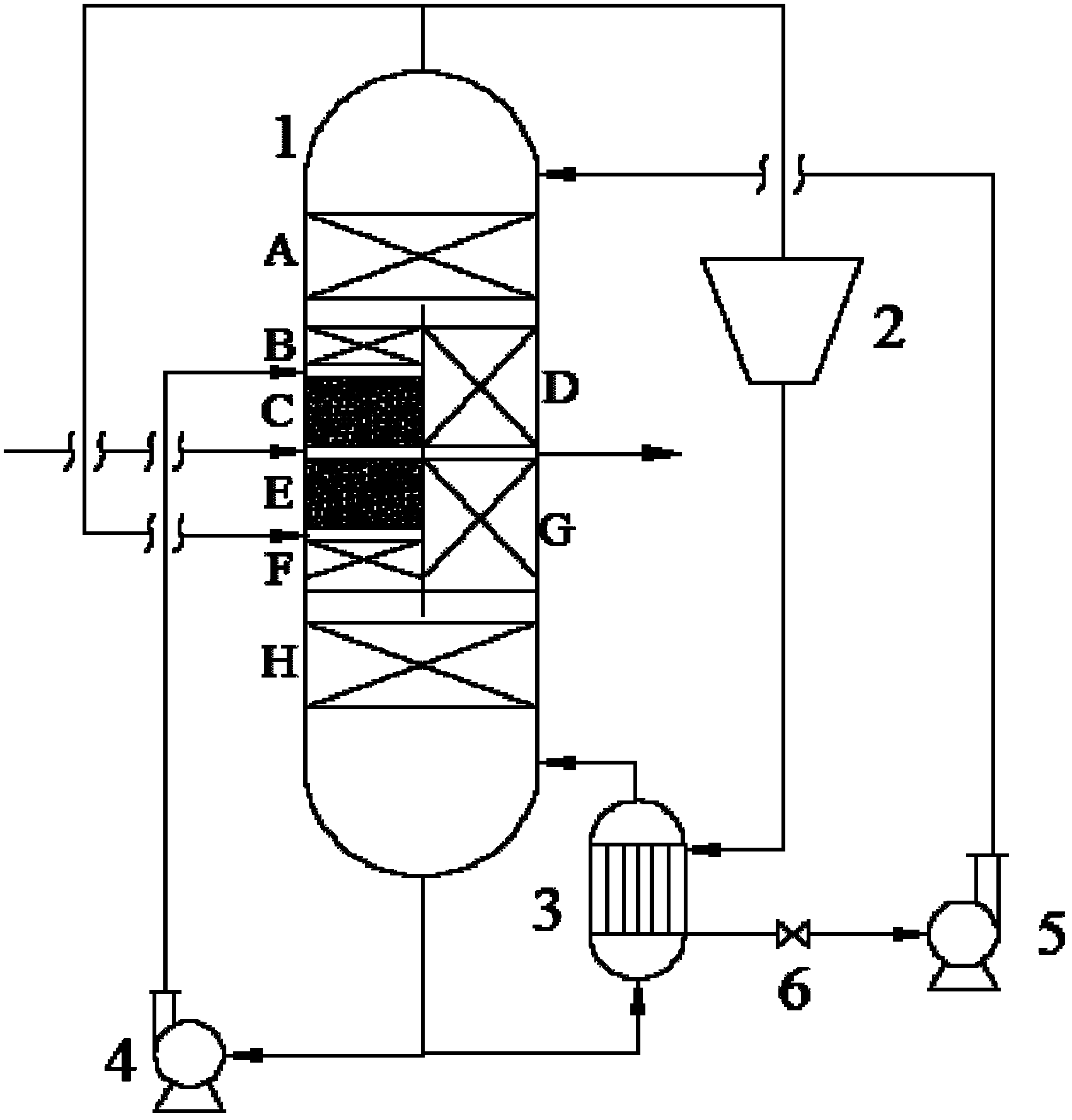

[0017] Concrete embodiment: public rectifying section A in the dividing wall tower, public stripping section H all have 6 theoretical plates, upper pre-fractionation section B, lower pre-fractionation section F all have 6 theoretical plates, upper production section D and lower The production section G has 12 theoretical plates, and the upper reaction section C and the lower reaction section E are filled with 2-meter-high reaction catalysts, and the solid-supported quaternary ammonium salts are selected as the reaction catalysts. The 2t / h mixed chlorosilane raw material enters the reaction section in the middle of the upper reaction section C and the lower reaction section E. The operating pressure is 0.5MPa, the temperature at the top of the tower is 62°C, and the temperature at the bottom of the tower is 114°C. The liquid phase on both sides of the separator is evenly distributed, that is, the liquid phase distribution on the upper part of the separator is such that the amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com