Inner blowout preventer of full-port drilling tool

An internal blowout prevention and full-bore technology, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve problems such as inability to run into well instruments or tools, and achieve reasonable structure, convenient use, The effect of reducing the cycle pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0019] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

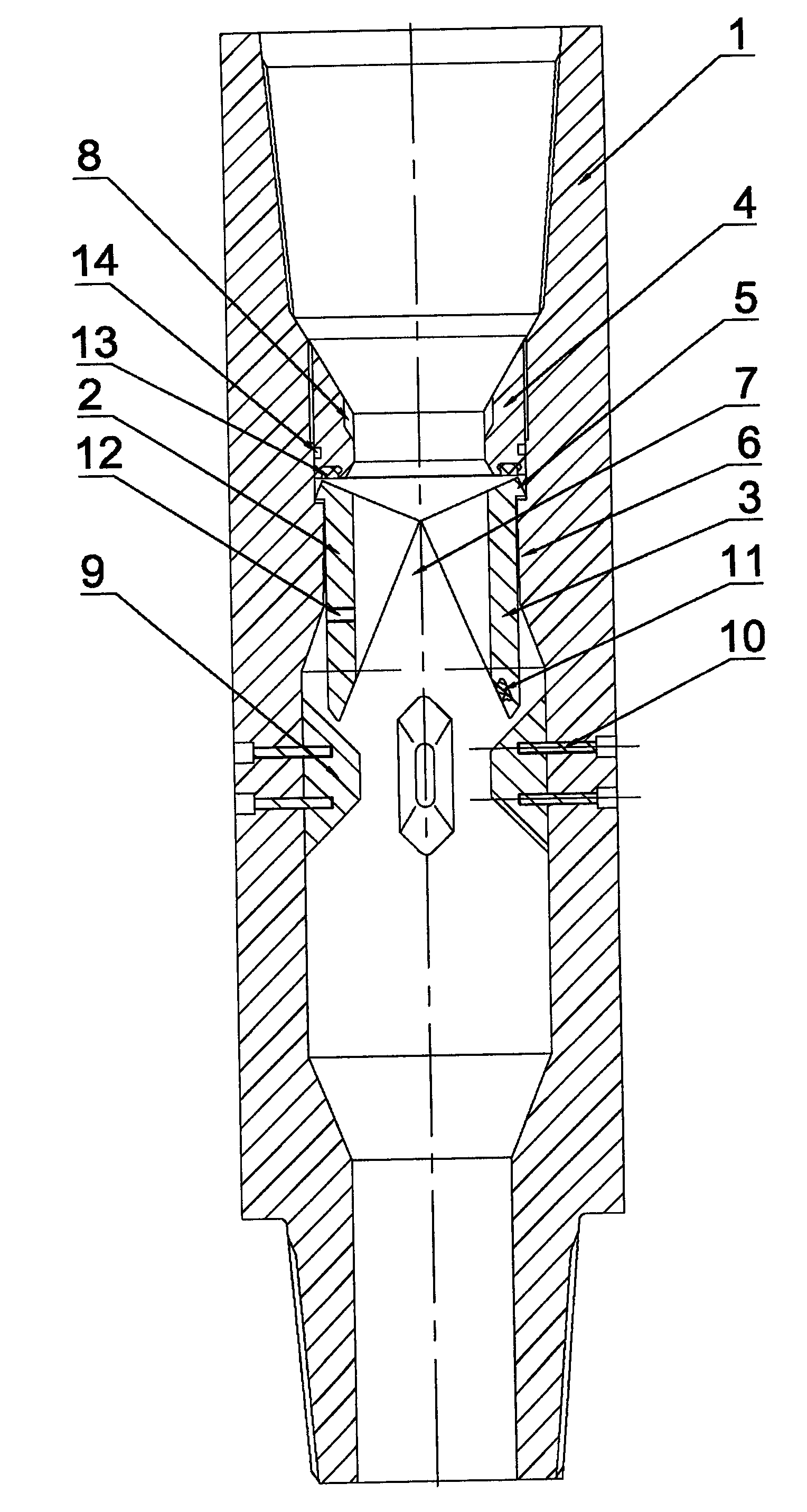

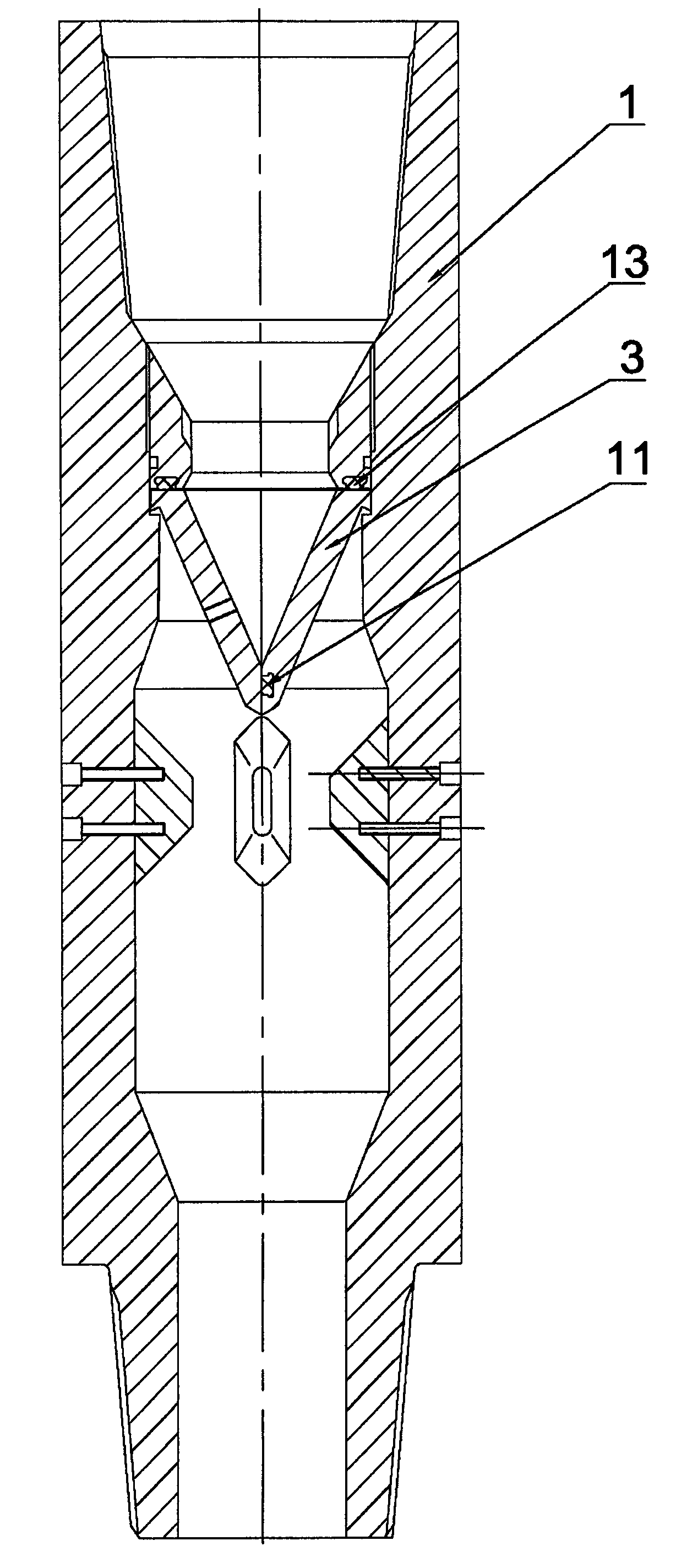

[0020] as attached figure 1 , 2 As shown, the blowout preventer in the full-bore drilling tool includes a valve body 1, a left valve plate 2, a right valve plate 3 and a fixed sleeve 4; there is a channel 7 in the valve body 1, the left valve plate 2 and the right valve plate 3 are semi-conical, and the upper ends of the left valve plate 2 and the right valve plate 3 have outwardly protruding outer flanges 5, and there are inner bosses 6 in the valve body 1, and the left valve plate 2 and the right valve plate The outer flange 5 of 3 hangs on the upper end surface of the inner boss 6 and is open to make the channel 7 in a smooth state. A valve body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com