High temperature abrasion-proof paint and method for producing the same

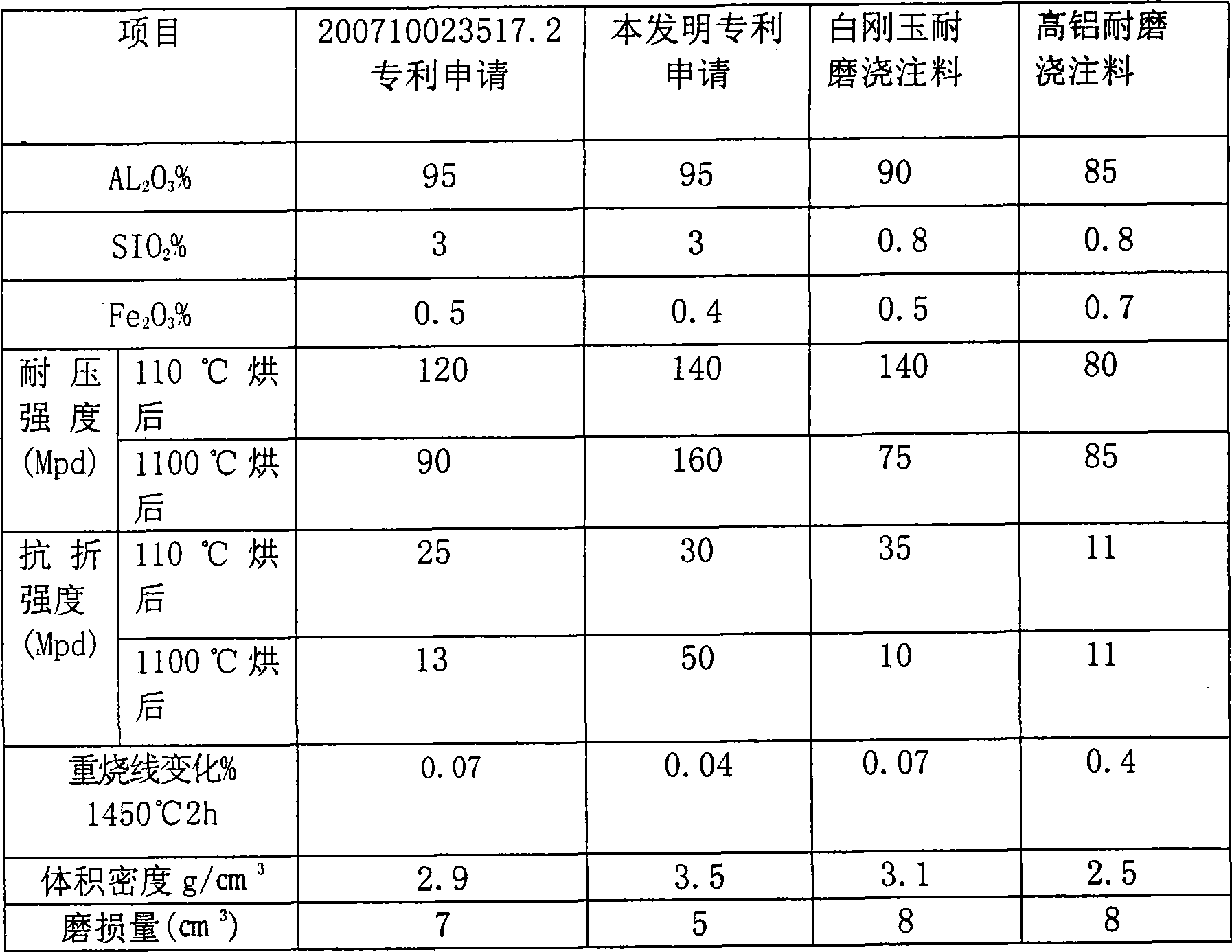

A high-temperature wear-resistant and coating technology, applied in the field of refractory materials, can solve the problems of wear resistance, erosion resistance, erosion resistance and thermal shock stability, which affect the normal operation of circulating fluidized bed boilers and consume manpower and financial resources and other problems, to achieve the effect of saving manpower and material resources, high density, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, high temperature wear-resistant coating, is made up of the first material of 70 parts of weight and the second material of 30 parts of weight, wherein:

[0029] The weight percentage of each component of material A is:

[0030] Zirconium corundum particle size 1 ~ 3mm 15%

[0031] Zirconium corundum particle size 0.4 ~ 1mm 35%

[0032] Corundum fine powder 220-250 mesh 20%

[0033] He No. 3 kyanite 180 mesh to 220 mesh 16%

[0034] Yttrium Stabilized Zirconium 3%

[0035] Silica powder SI≥98% Elkem silica powder 3%

[0036] Alumina fine powder 4%

[0037] Pure calcium aluminate cement 3%

[0038] Sodium tripolyphosphate 0.5%

[0039] Fused calcium chromate 0.5%;

[0040] The weight percent of each component of second material is:

[0041] Phosphoric acid 75%

[0042] Ink Grade Aluminum Hydroxide 15%

[0043] Zirconia superfine powder 5%

[0044] Yttrium Stabilized Zirconium 3%

[0045] Fused calcium chromate 2%

[0046] Among them: the concen...

Embodiment 2

[0048] Embodiment 2, high-temperature wear-resistant coating, is made up of the first material of 80 parts by weight and the second material of 20 parts by weight, wherein:

[0049] The weight percentage of each component of material A is:

[0050] Zirconium corundum particle size 1 ~ 3mm 19%

[0051] Zirconium corundum particle size 0.4 ~ 1mm 25%

[0052] Corundum fine powder 220-250 mesh 15%

[0053] He No. 3 kyanite 180 mesh to 220 mesh 10%

[0054] Yttrium Stabilized Zirconium 9%

[0055] Silica powder SI≥98% Elkem silica powder 7%

[0056] Alumina fine powder 8%

[0057] Pure calcium aluminate cement 5.5%

[0058] Sodium tripolyphosphate 0.3%

[0059] Fused calcium chromate 1.2%;

[0060] The weight percent of each component of second material is:

[0061] Phosphoric acid 85%

[0062] Ink Grade Aluminum Hydroxide 6%

[0063] Zirconia superfine powder 5%

[0064] Yttrium stabilized zirconium 3.7%

[0065] Fused calcium chromate 0.3%

[0066] Among them: the con...

Embodiment 3

[0068] Embodiment 3, high-temperature wear-resistant coating, is made up of the first material of 85 parts of weight and the second material of 15 parts of weight, wherein:

[0069] The weight percentage of each component of material A is:

[0070] Zirconium corundum particle size 1 ~ 3mm 25%

[0071] Zirconium corundum particle size 0.4 ~ 1mm 28%

[0072] Corundum fine powder 220-250 mesh 15%

[0073] He No. 3 kyanite 180 mesh to 220 mesh 10%

[0074] Yttrium Stabilized Zirconium 5%

[0075] Silica powder SI≥98% Elkem silica powder 5%

[0076] Alumina fine powder 5.4%

[0077] Pure calcium aluminate cement 4%

[0078] Sodium tripolyphosphate 0.1%

[0079] Fused calcium chromate 2.5%;

[0080] The weight percent of each component of second material is:

[0081] Phosphoric acid 75%

[0082] Ink grade aluminum hydroxide 7.7%

[0083] Zirconia superfine powder 7%

[0084] Yttrium Stabilized Zirconium 8%

[0085] Fused calcium chromate 2.3%

[0086] Among them: the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com