Optimization control method of multi-site conveyor belt feeding production processing site system

A technology for optimizing control and conveyor belts, applied in adaptive control, general control systems, control/regulation systems, etc., can solve problems such as unfavorable site load balance, difficult modeling, communication ability or perception ability limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

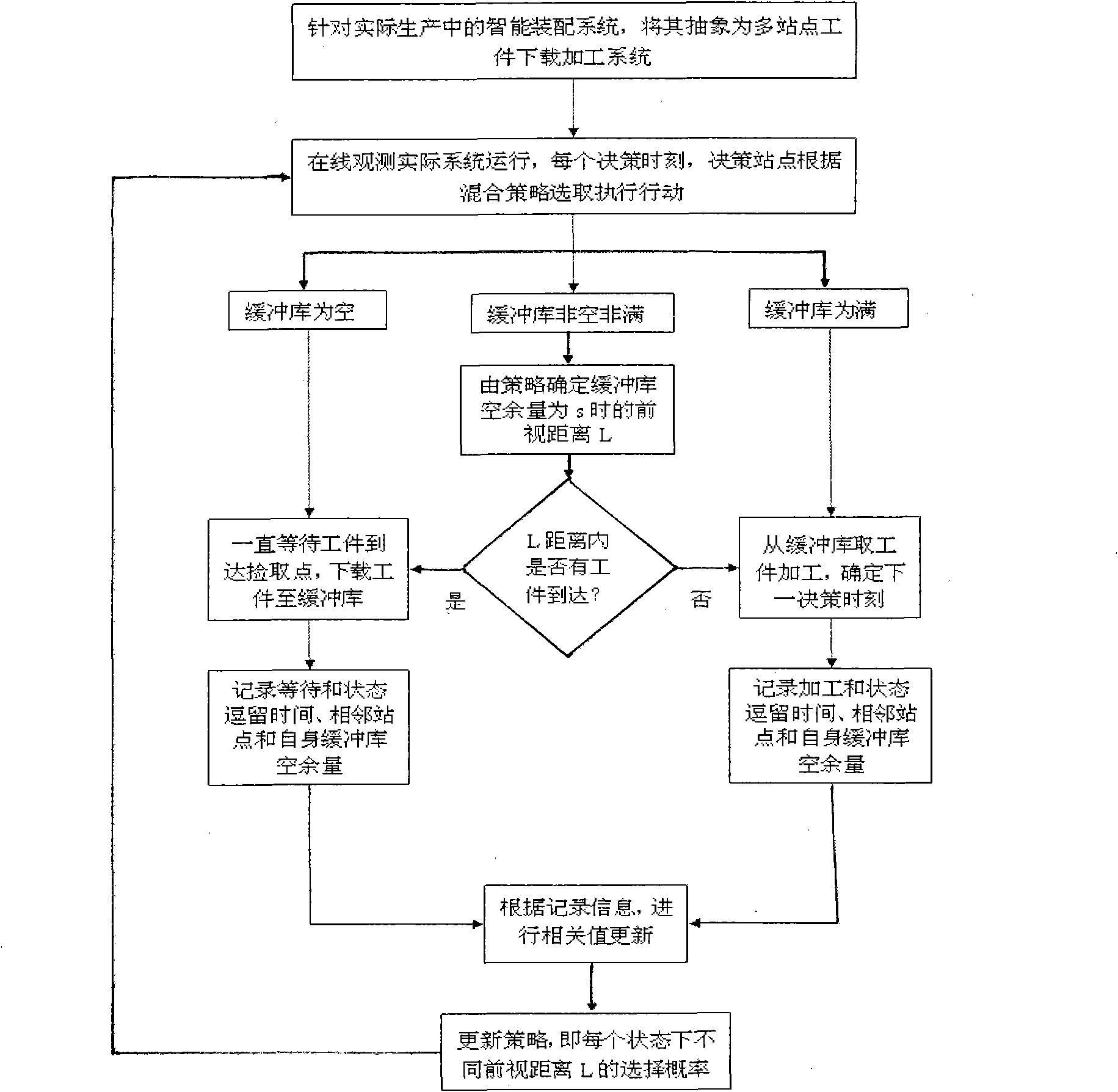

[0031] The concrete implementation process of the present invention is as follows:

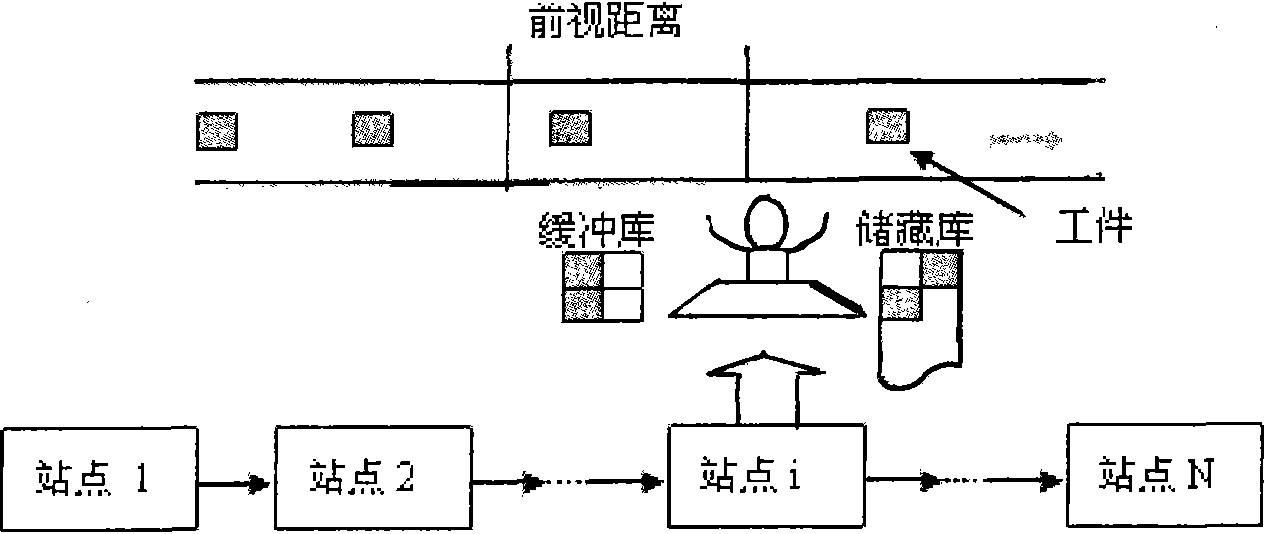

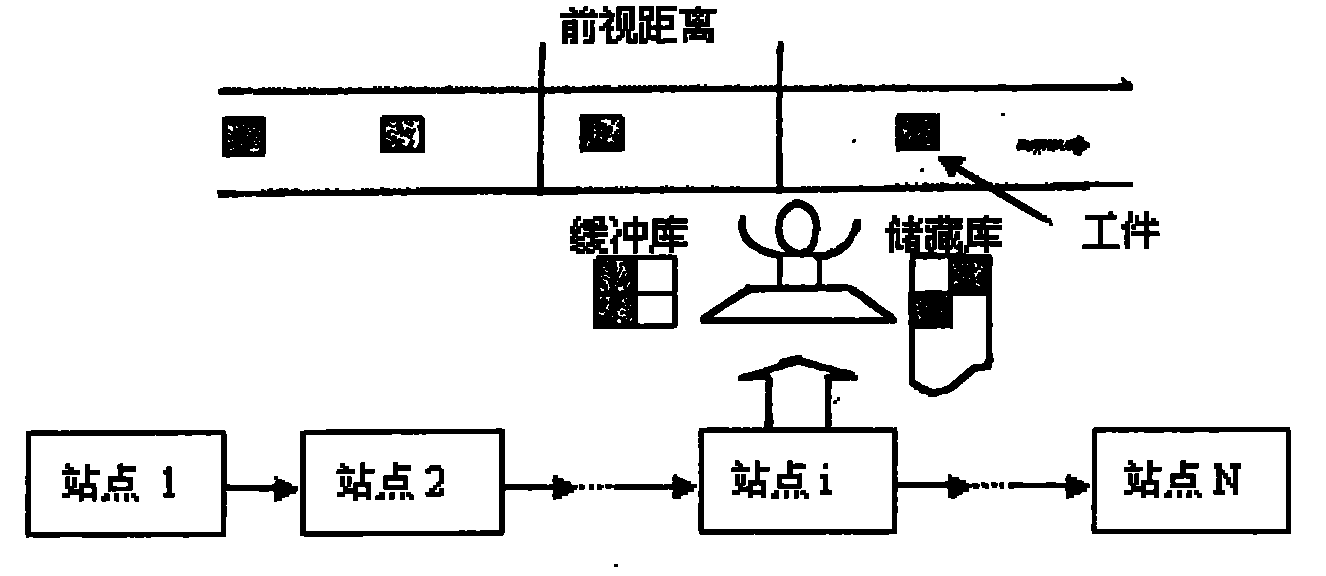

[0032] 1. For a specific intelligent assembly system in the actual production process, configure a conveyor belt to transmit the workpiece to be processed and connect several processing stations, such as figure 1 shown. Each processing site mainly includes processing subjects (humans, robots or robotic arms), buffer warehouses (storage of workpieces to be processed), storage warehouses (storage of finished workpieces) and forward-looking sensors (observation of workpiece flow information on the conveyor belt, such as cameras, radars, etc. ) and other devices. The station is recorded as i (i∈{1, 2, ..., N}, N is the number of stations), and the free space of the station buffer library is its own state variable, which is recorded as s i , its state space S={0, 1, 2,..., M} (M is the capacity of the buffer store), and the line-of-sight length L is the control action, and the action set D repres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com