Technological process for preparing stevioside from stevia rebaudiana bertoni

A technology of steviol glycoside and stevia, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of large loss and high cost of stevioside, achieve safe preparation process, low extraction cost, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

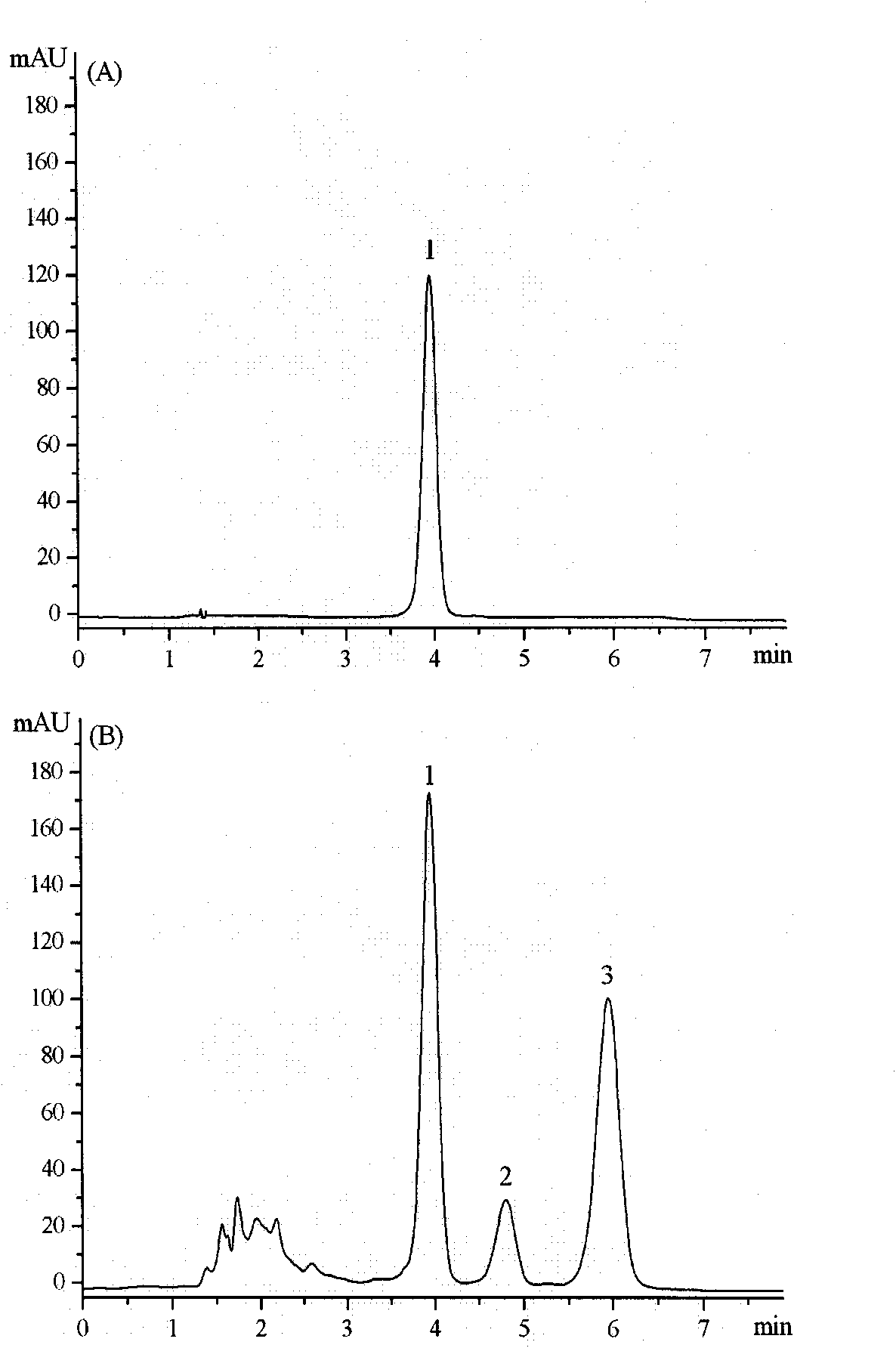

Embodiment 1

[0027] Weigh 100 g of dried stevia leaves, place them in a countercurrent extraction device, add 1000 mL of water for countercurrent extraction, control the temperature at 50 ° C, and conduct countercurrent extraction for 2 hours. Take by weighing 2 parts of pre-treated macroporous adsorbent resin, each part of 120g, and put them into two glass columns with an internal diameter of 3cm and a column height of 36cm (diameter-to-height ratio 1:12) by wet method, and the two columns are connected in series (column I, column II column). The extract obtained by countercurrent extraction flows through series resin columns (column I, column II) for adsorption in sequence, the flow rate is 30BV / h, and the temperature of the resin column is controlled at 40°C. After adsorption, the residual liquid enters the countercurrent extraction device again for the second countercurrent extraction , the extraction time is 2h, the temperature is 50°C, after the extraction is completed, the extract i...

Embodiment 2

[0029]Weigh 1 kg of dried stevia leaves, place in a countercurrent extraction device, add 15 L of water for countercurrent extraction, control the extraction temperature at 60° C., and conduct countercurrent extraction for 1.5 h. Take by weighing 2 parts of pre-treated macroporous adsorbent resins, each part of 0.9Kg, put into two glass columns with internal diameter 6cm, column height 66cm (diameter-to-height ratio 1: 11) respectively by wet method, and two columns are connected in series (I column , II column). The extract obtained by countercurrent extraction was sequentially flowed through series resin columns (column I, column II) for adsorption at a flow rate of 30BV / h, and the temperature of the resin column was controlled at 40°C. After the adsorption, the residual liquid enters the countercurrent extraction device again for the second countercurrent extraction. The extraction time is 1.5h and the temperature is 60°C. After the extraction is completed, the extract is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com