Edible and medical fungus cell component comprehensive extraction method and use of extract

A technology for the comprehensive extraction of edible and medicinal fungi, applied in the fields of application, food science, food preparation, etc., can solve the problems of destroying the flavor of the subsequent extract, reducing the extraction rate of the subsequent process, and protein denaturation, so as to achieve full utilization of raw materials and reduce The effect of improving extraction cost and extraction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

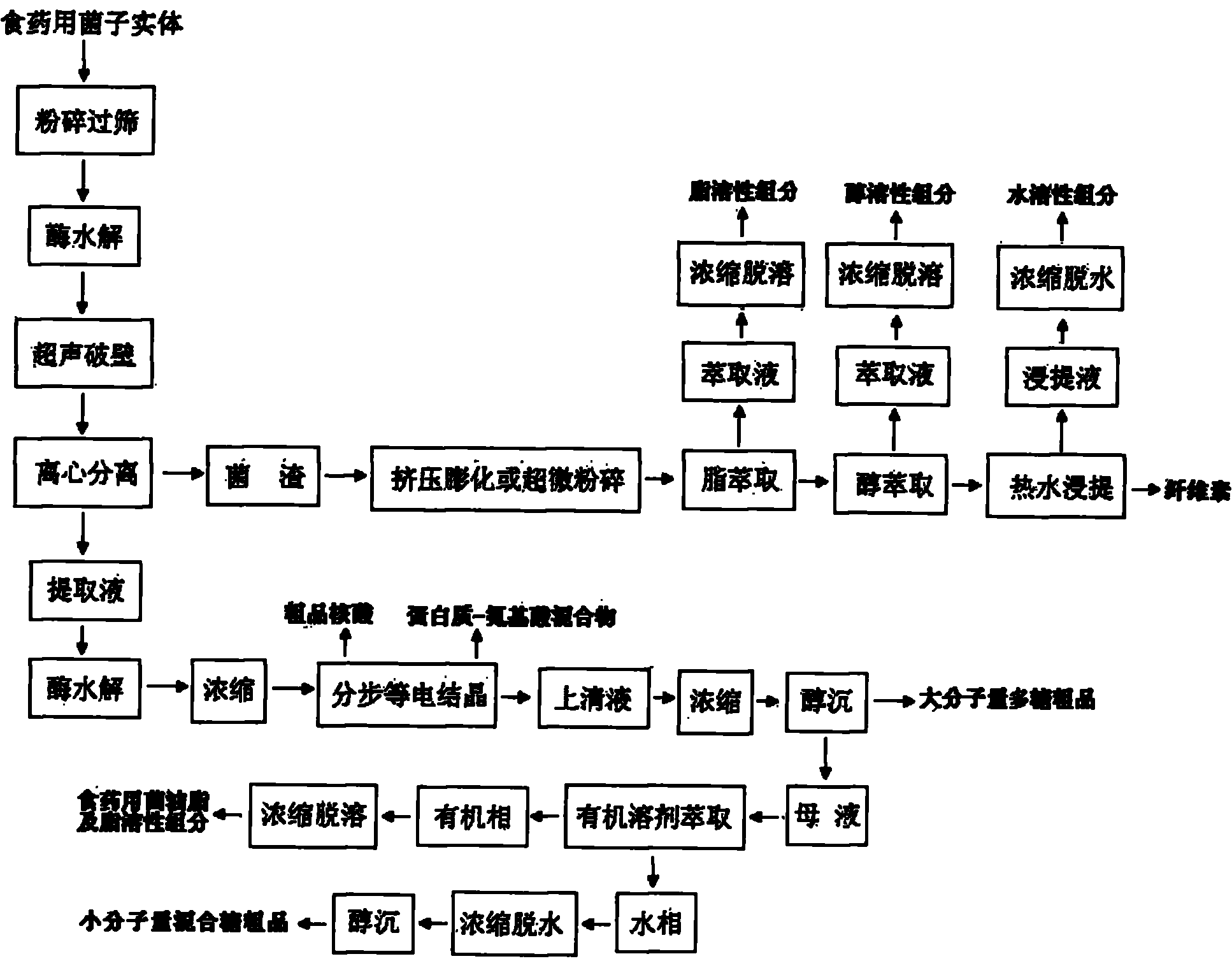

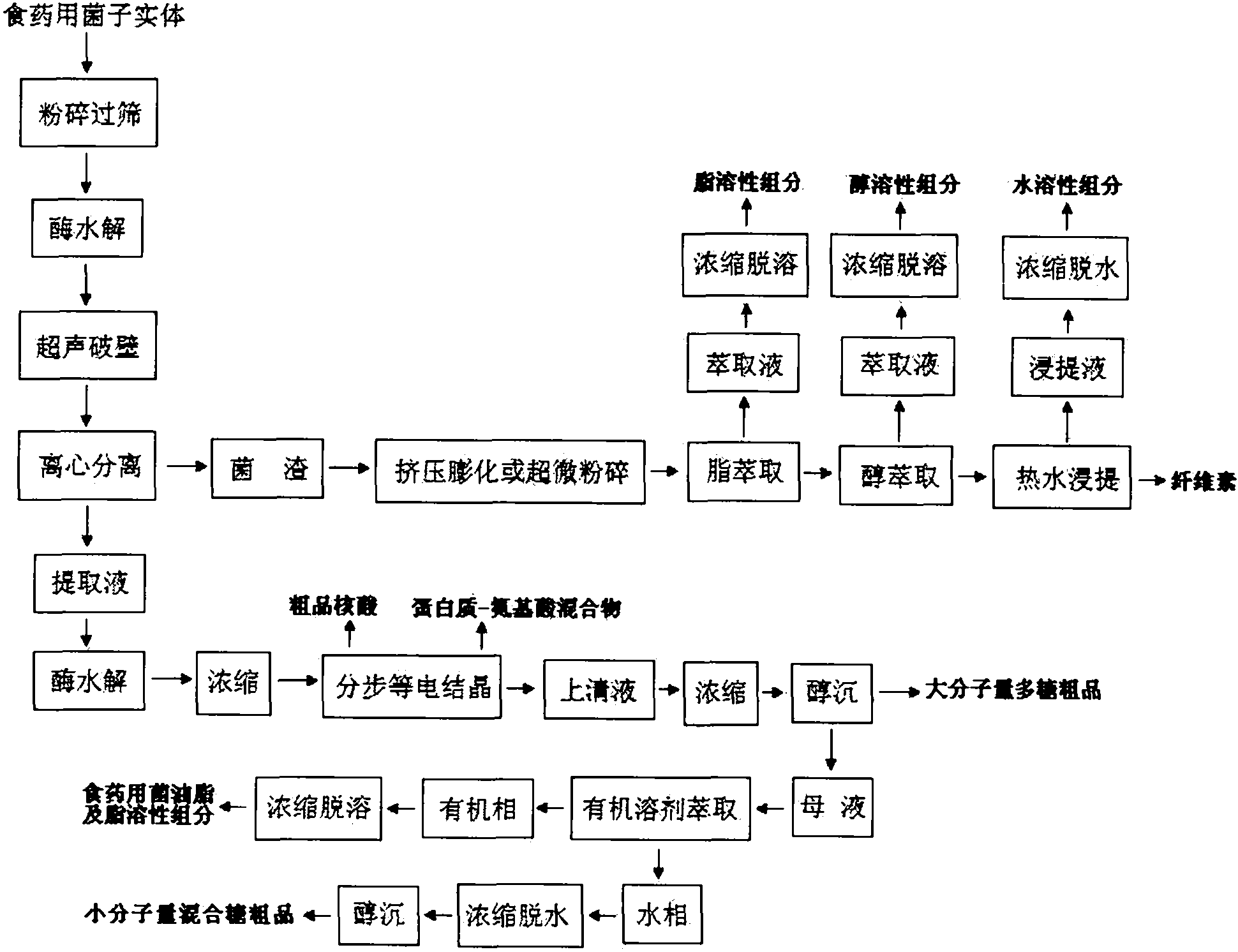

Image

Examples

Embodiment 1

[0052] 1. Select the dry fruiting bodies of shiitake mushrooms, crush them to pass through a 150-mesh sieve; weigh 1000g of shiitake mushroom dry powder, add water according to the ratio of material to liquid of 1:35 (weight ratio), and stir evenly.

[0053] 2. Adjust the pH value to 4.8, add cellulase with 0.5% weight of dry mushroom powder and pectinase with 0.5% weight of dried mushroom powder at the same time, stir and hydrolyze for 1.5 hours at 55° C.; protease, hydrolyzed at 55°C for 2 hours with stirring.

[0054] 3. The material liquid adopts the conditions of 800w, 25KHz, and 30°C, and ultrasonically breaks the wall for 30 minutes. After the wall breaking is completed, centrifuge at 4000 rpm for 15 minutes to obtain the extract and bacteria residue.

[0055] 4. Treatment of extract

[0056] (1) Add papain at 0.5% by weight of dry mushroom powder and soybean polypeptide hydrolase at 0.3% by weight to the extract at the same time, pH 7.0, stir and hydrolyze at 55° C. ...

Embodiment 2-9

[0067] Edible and medicinal fungi are selected from Hericium erinaceus, Coprinus comatus, tea tree mushroom, Pleurotus eryngii, fungus, Ganoderma lucidum, Agaricus blazei, or one of the fruiting bodies of the edible and medicinal fungi of Grifola frondosa.

[0068] The operating conditions are the same as in Example 1, and the extracts of the corresponding edible and medicinal fungus cell components are also obtained.

Embodiment 10

[0070] Using the method of Example 1, from 1000g shiitake mushroom dry powder, extract 120g (dry weight) of shiitake mushroom protein-amino acid mixture, 30g (dry weight) of shiitake mushroom nucleic acid crude product. The two extracts are mixed, and then mixed with extract: monosodium glutamate (containing 99% sodium glutamate): taste sodium nucleotide (99% purity): salt is mixed evenly according to the weight ratio of 40:38:2:20 , packaged, that is, special mushroom seasoning powder, its umami taste is 3 times that of ordinary MSG, and has a strong mushroom flavor at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com