Preparation method for novel red ginseng using reduced-pressure drying after high temperature high pressure process

A manufacturing method, high temperature and high pressure technology, applied in the direction of medical preparations containing active ingredients, food preparation, pharmaceutical formulations, etc., can solve the problems of circular ginseng shape rupture, unstable heat and extraction time changes, long-term problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

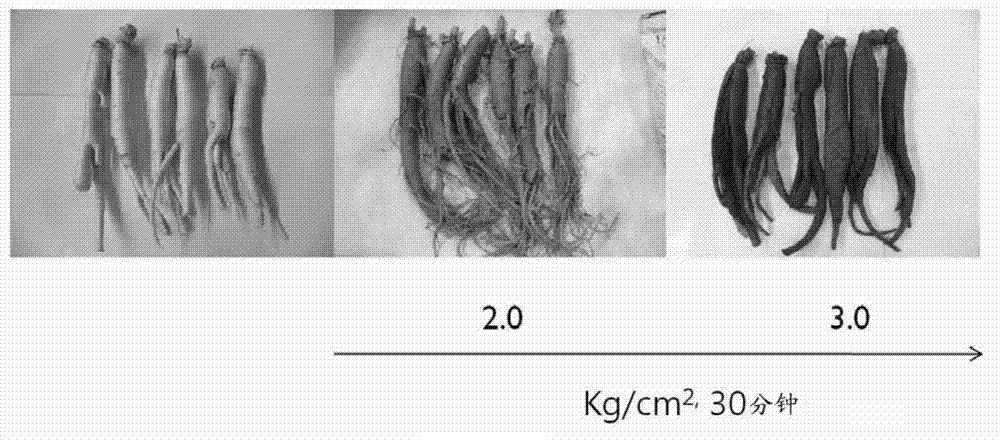

[0057] Experimental example 1: Appearance change of raw ginseng by high temperature and high pressure treatment

[0058] 6-year-old raw ginseng with a water content of 72% by weight is washed, the tail is removed, and the pressure is 2kgf / cm 2 and 3kgf / cm 2 After steaming at high temperature and high pressure for 30 minutes, take it out from the autoclave, and check whether the round ginseng is maintained or not.

[0059] figure 1 The left side of the photo is the photo of the raw ginseng after washing and removing the tail, and the middle is the photo of the raw ginseng with 2kgf / cm 2 The photo of steamed red ginseng, on the right is 3kgf / cm 2 Photo of steamed red ginseng.

[0060] Under the production conditions of ordinary red ginseng, without additional drying of raw ginseng, steaming for a long time at 80-100°C under atmospheric pressure will not cause cracks on the surface of red ginseng, but raw ginseng with high moisture content can be dried at 2kgf / cm 2 Red gin...

experiment example 2

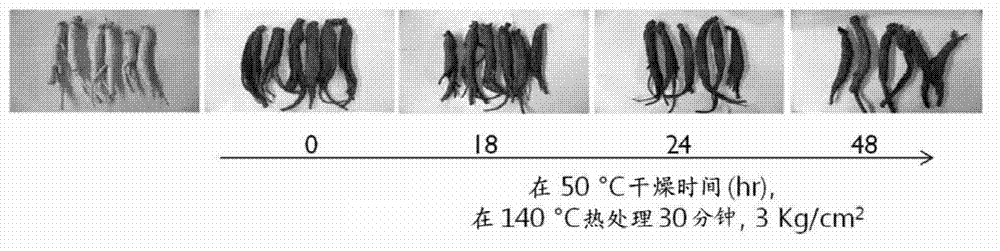

[0061] Experimental example 2: Appearance change of raw ginseng by pre-drying high temperature and high pressure treatment

[0062] Wash the 6-year-old raw ginseng, remove the tail, and dry it with hot air at 50°C for 12, 24 and 48 hours respectively. 2 Steamed at high temperature and high pressure for 30 minutes to check whether the shape of red ginseng is cracked or not according to the pre-drying conditions.

[0063] First, the water content of ginseng according to the drying time is shown in Table 1.

[0064] Table 1

[0065] differentiate

Moisture content (weight%)

Raw ginseng without pre-drying

72.18±0.36

Ginseng dried for 12 hours

54.29±1.19

Ginseng dried for 24 hours

43.54±1.73

Ginseng dried for 48 hours

9.20±0.04

[0066] figure 2 The first photo from the left is raw ginseng washed and tail removed, and the second to fifth photos are raw ginseng without pre-drying, ginseng dried for 12 hours, ginseng ...

experiment example 3

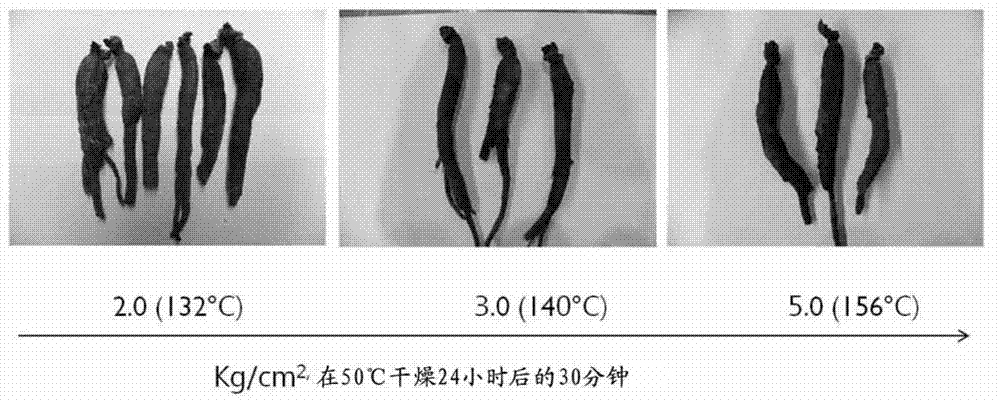

[0068] Experimental example 3: Appearance change of pre-dried ginseng according to high temperature and high pressure treatment pressure

[0069]Wash the 6-year-old raw ginseng, remove the tail, and dry it with hot air at 50°C for 24 hours, then change the pressure at 2, 3 and 5kgf / cm 2 Steam the dried ginseng under high temperature and high pressure for 30 minutes, and confirm that the pre-drying is at 2-5kgf / cm 2 Whether it can prevent the appearance of red ginseng from breaking under high temperature and high pressure conditions.

[0070] image 3 The left side is at 2kgf / cm 2 Steamed red ginseng, the center is at 3kgf / cm 2 Steamed red ginseng, the right side is at 5kgf / cm 2 Photo of steamed red ginseng.

[0071] Thus confirming that at 2~5kgf / cm 2 The range of pressure conditions can prevent the appearance of red ginseng from being broken by pre-drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com