Method for enriching scandium, titanium and vanadium from sulfuric acid method titanium dioxide waste acid, and for treating waste acid

A technology for the treatment of titanium dioxide waste acid and waste acid, which is applied in neutralization water/sewage treatment, chemical instruments and methods, natural water treatment, etc. It can solve problems such as complex process and achieve the effect of reducing extraction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

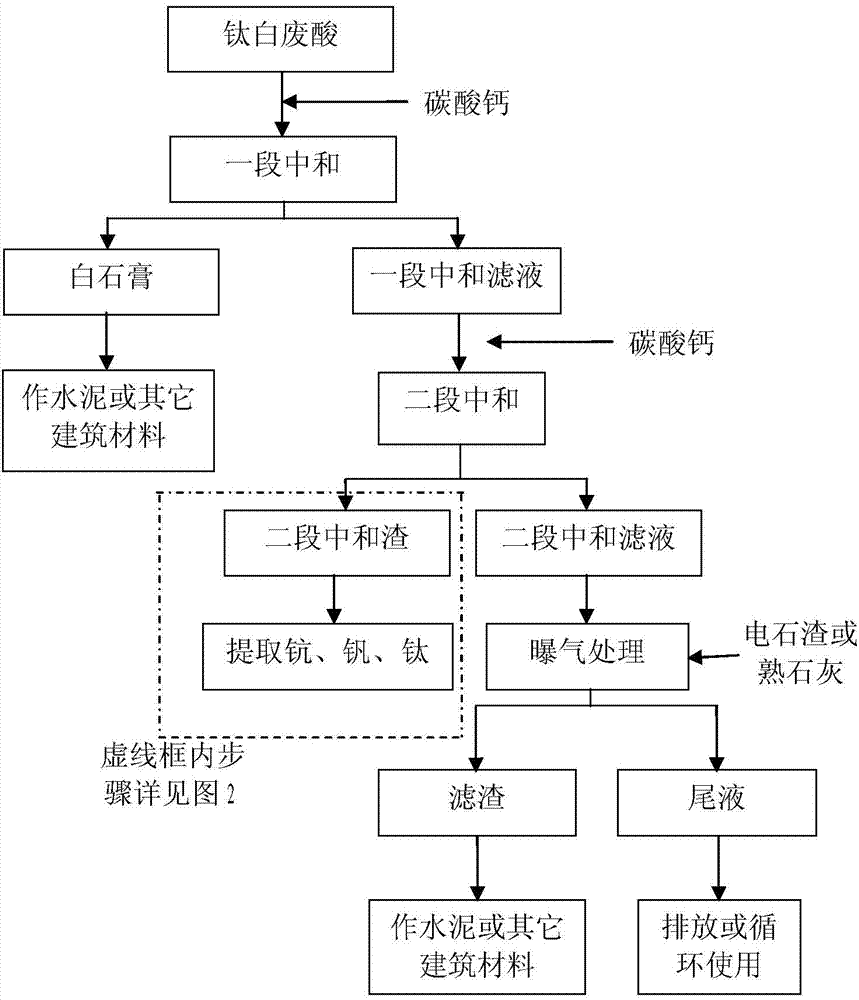

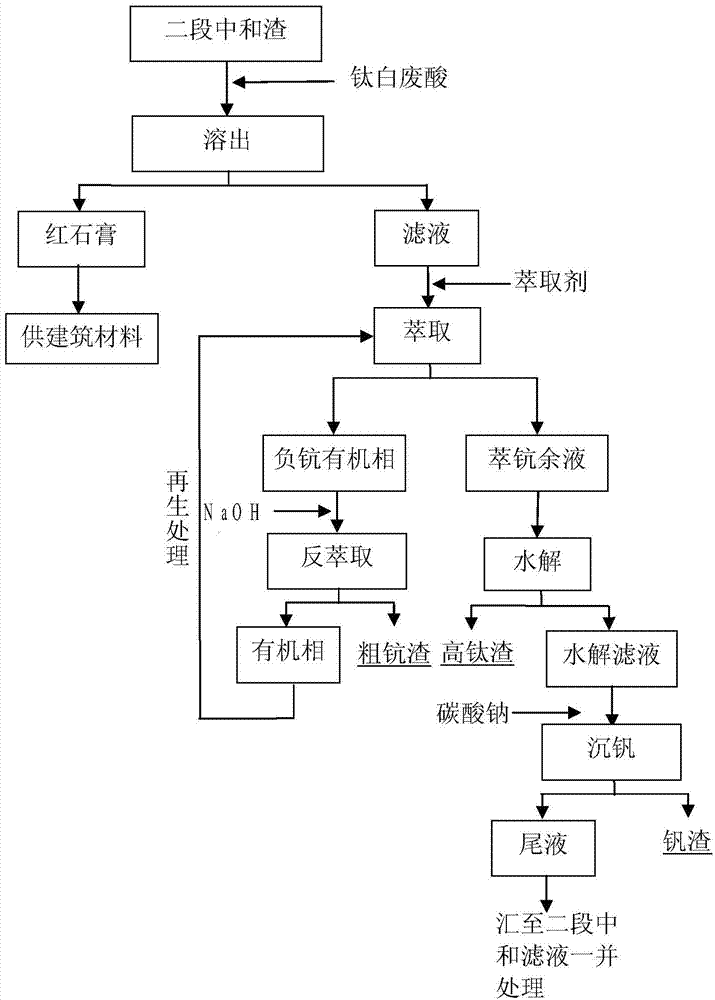

[0022] like figure 1 , figure 2 As shown, the method for enriching scandium, titanium and vanadium and the waste acid treatment thereof from the waste acid of titanium dioxide by sulfuric acid method of the present invention comprises the following steps:

[0023] Add H to a 200L reaction tank + 100L of titanium dioxide waste acid with a concentration of 5.92mol / L, in which Sc 2 O 3 The content is 32.8mg / L, V 2 O 5 The content is 1.00g / L, TiO 2 The content is 7.00g / L, and 30kg calcium carbonate is added to carry out one-stage neutralization. The pH value of the reaction end point is 1.0-2.0. 2 O 3 The content is 16.74mg / L, V 2 O 5 The content is 0.52g / L, TiO 2 The content is 3.7g / L. This step Sc 2 O 3 , V 2 O 5 and TiO 2 The recoveries were 86.76%, 88.4% and 89.86%, respectively.

[0024] Add 3kg of calcium carbonate to the first-stage neutralization filtrate to carry out the second-stage neutralization. The pH value of the reaction end point is 4.0 to 5.0. A...

Embodiment 2

[0031] In a 200L reaction tank, add 100L of titanium dioxide waste acid with a H concentration of 5.51mol / L, wherein Sc 2 O 3 The content is 24.5mg / L, V 2 O 5 The content is 0.87g / L, TiO 2 The content is 6.76g / L, and 27kg of calcium carbonate is added for one-stage neutralization. The pH value of the reaction end point is 1.0-2.0. After pressure filtration and two washings, a first-stage neutralization filtrate and white gypsum are obtained. 2 O 3 The content is 12.52mg / L, V 2 O 5 The content is 0.46g / L, TiO 2 The content is 3.52g / L. This step Sc2 O 3 , V 2 O 5 and TiO 2 The recoveries were 88.67%, 89.89% and 88.52%, respectively.

[0032] Add 2.7kg of calcium carbonate to the first-stage neutralization filtrate to carry out the second-stage neutralization. The pH value of the reaction end point is 4.0 to 5.0. After pressure filtration, the second-stage neutralization slag and the second-stage neutralization filtrate are obtained. The Sc in the second-stage neutral...

Embodiment 3

[0039] Add H to a 200L reaction tank + 100L of titanium dioxide waste acid with a concentration of 4.49mol / L, in which Sc 2 O 3 The content is 13.5mg / L, V 2 O 5 The content is 0.6g / L, TiO 2 The content is 3.9g / L, and 22kg of calcium carbonate is added for one-stage neutralization. The pH value of the reaction end point is 1.0-2.0. 2 O 3 The content is 6.95mg / L, V 2 O 5 The content is 0.31g / L, TiO 2 The content is 2.0g / L. This step Sc 2 O 3 , V 2 O 5 and TiO 2 The recoveries were 87.52%, 87.83% and 87.18%, respectively.

[0040] 2.2kg of calcium carbonate was added to the first-stage neutralization filtrate to carry out the second-stage neutralization. The pH value of the reaction end point was 4.0 to 5.0. After pressure filtration, the second-stage neutralization slag and the second-stage neutralization filtrate were obtained. 2 O 3 The content is 0.0219%, V 2 O 5 The content is 0.98%, TiO 2 The content is 6.3%. The second-stage neutralization filtrate is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com