Method for extracting and separating eucommia ulmoides rubber

A technology of eucommia gum and eucommia polysaccharide, which is applied in the field of extraction and separation of natural product eucommia gum, which can solve the problems of smaller molecular weight, large consumption of organic solvents, reduction of elasticity, toughness and tensile strength of eucommia gum, and improve quality and yield , The effect of low extraction and separation temperature and short extraction and separation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

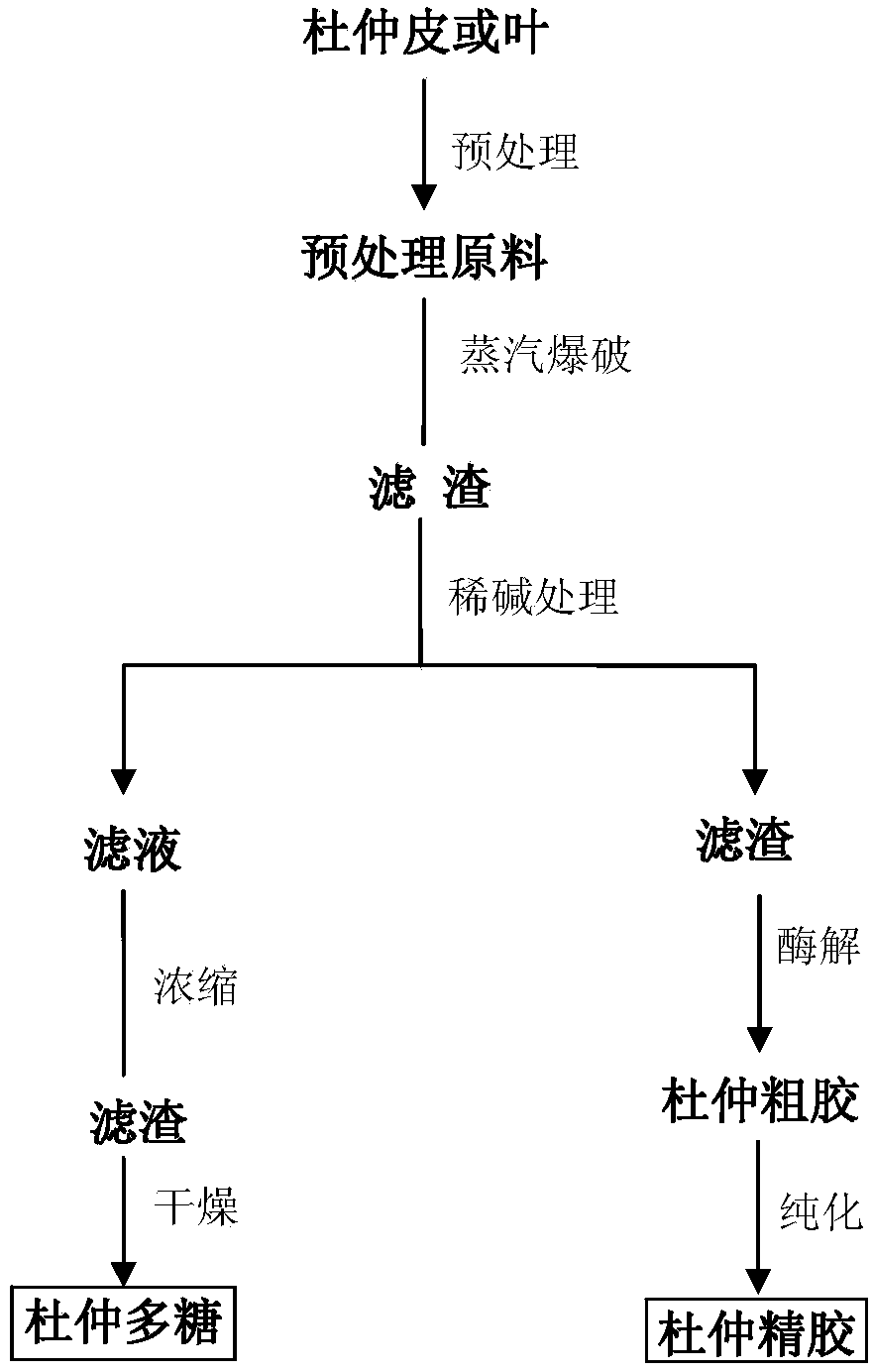

[0027] A method for extracting and separating eucommia gum, comprising the steps of:

[0028] (1) Pre-treatment: the bark of Eucommia ulmoides, after removing impurities, passed the inspection according to the quality requirements of the Chinese Pharmacopoeia, and the dried bark of Eucommia was properly crushed by machinery, with a particle size of 1 cm, and placed in a dry and cool place for later use ;

[0029] (2) Steam explosion: Put the material processed in step (1) into a steam explosion device for steam explosion. The pressure of the steam explosion is 0.5MPa. 15min, the material temperature is room temperature after steam explosion;

[0030] (3) Mix the filter residue in step (2) with 0.5% NaOH solution according to the ratio of solid-liquid ratio of 1:5, extract at 60°C for 3 hours, filter, pump to the liquid storage tank, and perform secondary extraction When mixing according to the material-liquid ratio of 1:15, the extraction temperature and time are the same as...

Embodiment 2

[0034] A method for extracting and separating eucommia gum, comprising the steps of:

[0035] (1) Pre-treatment: the bark of Eucommia ulmoides, after impurity removal treatment, passed the inspection according to the quality requirements of the Chinese Pharmacopoeia, and the dried bark of Eucommia was properly crushed by machinery, with a particle size of 10 cm, and placed in a dry and cool place for later use ;

[0036] (2) Steam explosion: Put the material processed in step (1) into a steam explosion device for steam explosion. The pressure of the steam explosion is 1.2MPa. 8min, the material temperature is room temperature after steam explosion;

[0037] (3) Mix the filter residue in step (2) with 2% NaOH solution according to the ratio of solid-liquid ratio of 1:10, extract at 70°C for 2 hours, filter, pump to the liquid storage tank, and perform secondary extraction When mixing according to the material-liquid ratio of 1:5, the extraction temperature and time are the sa...

Embodiment 3

[0041] A method for extracting and separating eucommia gum, comprising the steps of:

[0042] (1) Pre-treatment: the bark of Eucommia ulmoides, after impurity removal treatment, passed the inspection according to the quality requirements of the Chinese Pharmacopoeia, and the dried bark of Eucommia was properly crushed by machinery, with a particle size of 5 cm, and placed in a dry and cool place for later use ;

[0043] (2) Steam explosion: Put the material processed in step (1) into a steam explosion device for steam explosion. The pressure of the steam explosion is 1.8MPa. 1min, the material temperature is room temperature after steam explosion;

[0044] (3) Mix the filter residue in step (2) with 4% NaOH solution according to the ratio of solid-liquid ratio of 1:20, extract at 80°C for 1 hour, filter, pump to the liquid storage tank, and perform secondary extraction When mixing according to the material-liquid ratio of 1:10, the extraction temperature and time are the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com