Simple method for extracting natural taurine

A taurine, natural technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of large environmental pollution, large number of ion exchange resin regeneration, high cost, high extraction rate and production cost. Low, high utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

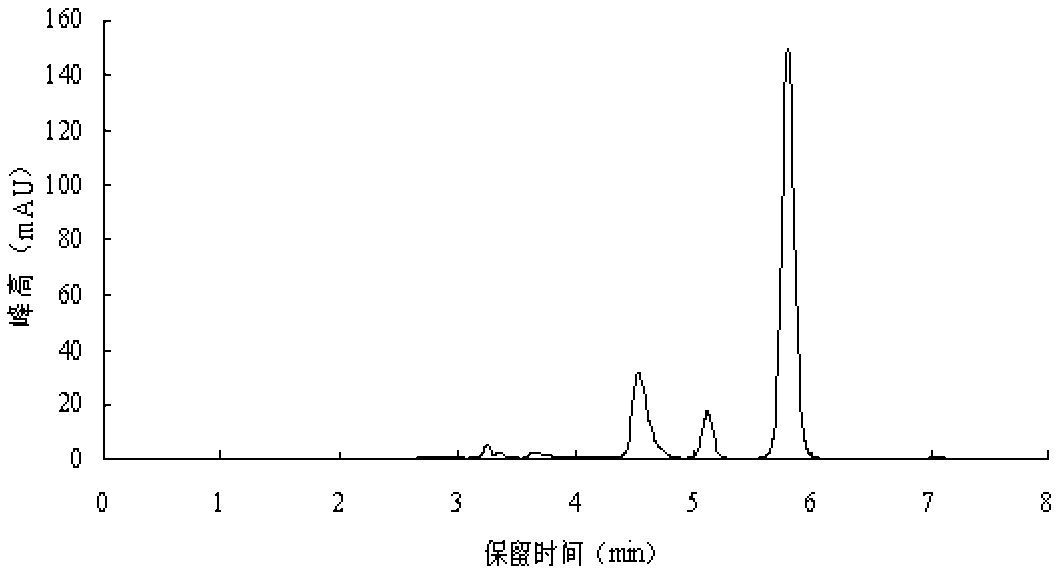

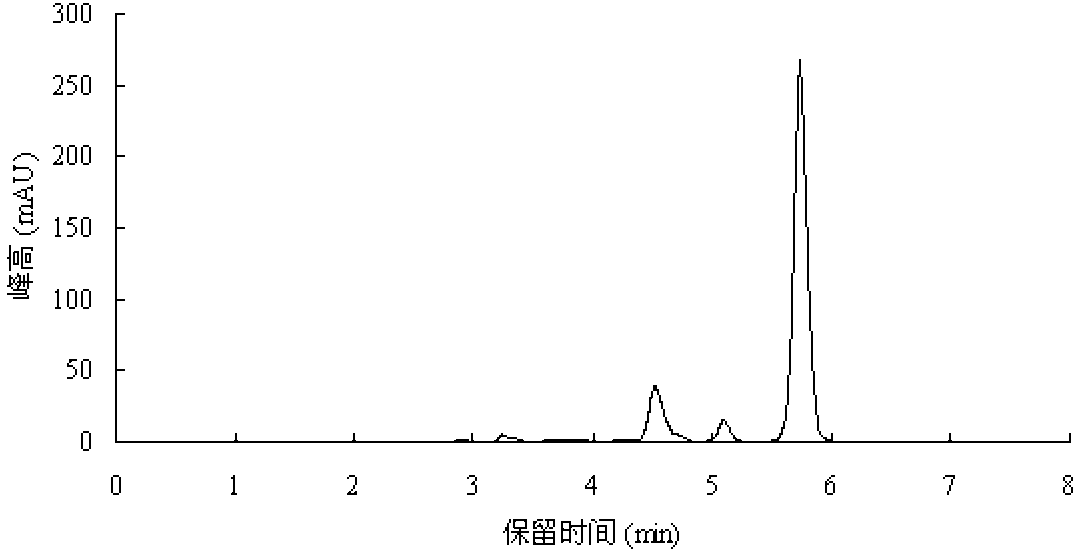

Image

Examples

Embodiment 1

[0031] Example 1: Extraction of natural taurine

[0032] (1) Raw material pretreatment: After cleaning the clams, cook them at 80°C for 60 minutes, collect the soup, heat and concentrate the soup to a solid content of 8%, and then use it as the raw material for extraction;

[0033] (2) Ethanol removal of impurities: Take 150 mL clam concentrated broth, add 450 mL 95% ethanol, stir at 70 °C for 40 min, and filter with suction to obtain the filtrate and precipitate. Add 100 mL of water and 450 mL of ethanol to the obtained precipitate, stir at 70 °C for 40 min, and filter with suction to obtain the filtrate and precipitate. Combine two filtrates to obtain supernatant;

[0034] (3) Concentration: The supernatant was concentrated by vacuum concentration to a soluble solid content of 44.5%. During the decompression concentration process, the temperature is kept at 70~80°C, and the vacuum degree is kept at -0.1~0.09 Mpa;

[0035] (4) Crystallization: After adding 3 times the v...

Embodiment 2

[0037] Example 2: Extraction of natural taurine

[0038] (1) Raw material pretreatment: After the clams were sanded and cleaned, they were steamed at 100 °C for 40 minutes, the soup was collected, and the soup was heated and concentrated to a solid content of 7% as the raw material for extraction;

[0039] (2) Ethanol removal of impurities: Take 300 mL clam concentrated broth, add 900 mL 95% ethanol, stir at 70 °C for 120 min, and obtain precipitate and filtrate. The filtrate was treated with activated carbon to obtain a supernatant;

[0040] (3) Concentration: The supernatant was concentrated by vacuum concentration to a soluble solid content of 48%. During the decompression concentration process, the temperature is kept at 70~80°C, and the vacuum degree is kept at -0.1~0.09 Mpa;

[0041] (4) Crystallization: After adding 3 times the volume of absolute ethanol to the concentrated solution, immediately remove impurities by suction filtration, and place the filtrate at 4 °C...

Embodiment 3

[0043] Example 3: Extraction of natural taurine

[0044] (1) Raw material pretreatment: after spitting and cleaning the variegated clams, steam them at 120 °C for 20 minutes, collect the soup, heat and concentrate the soup to a solid content of 8%, and then use it as the raw material for extraction;

[0045] (2) Ethanol removal of impurities: take 600 mL of concentrated clam broth, add 1800 mL of 95% ethanol, stir at 70 °C for 40 min, and obtain the precipitate and supernatant;

[0046](3) Concentration: The supernatant was concentrated by vacuum concentration to a soluble solid content of 45.5%. During the decompression concentration process, the temperature is kept at 70~80°C, and the vacuum degree is kept at -0.1~0.09 Mpa;

[0047] (4) Crystallization: After adding 3 times the volume of absolute ethanol to the concentrated solution, immediately remove impurities by suction filtration, and place the filtrate at 4 °C for more than 24 h to crystallize. Suction filtration a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com