The preparation method of polyphenylsulfone resin

A polyphenylsulfone and resin technology is applied in the field of preparation of polyphenylsulfone resin, which can solve the problems of discontinuous process flow, unclean polymer product purity, low purity, etc., to ensure purity and performance, high purity, and overcome ash content. lower effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present invention provides a preparation method of polyphenylsulfone resin, including polymerization reaction and precipitation and purification treatment of reaction products, wherein:

[0021] The raw materials of the polymerization reaction and their molar ratios are: 4,4'-dichlorodiphenyl sulfone: biphenol: catalyst: sulfolane: dehydrating agent=1:1:1.09~1.2:5.7~6.2:1.1~1.2;

[0022] The precipitation treatment of the reaction product is as follows: after the polymerization reaction is completed, the reaction temperature is first reduced to 100-120°C (preferably 110°C), and at the same time, sulfolane diluted raw material is added to the reactor, the amount of sulfolane added and the addition during the polymerization reaction The sum of the mass of sulfolane is 4 to 5 times the sum of the mass of 4,4'-dichlorodiphenyl sulfone and biphenyl diphenol; then the sedimentation liquid is added dropwise to the reactor, and the addition amount of the sedimentation liquid acco...

Embodiment 1

[0040] Take a 200L polymerizer as an example, prepare the raw materials according to the following quality: 4,4'-dichlorodiphenyl sulfone (16.08Kg), biphenol (10.43Kg), potassium carbonate (8.5Kg), sulfolane (40Kg), Trimethylbenzene (7.95Kg).

[0041] Weigh the above formula components accurately, and add sulfolane and 4,4'-dichlorodiphenyl sulfone into a 200L polymerizer equipped with a water separator, agitator (frame type and two-way stirring) and a heating device. Biphenyl diphenol and trimethyl benzene, pass inert gas nitrogen protection, start stirring (frame stirring 30r / min, paddle stirring 60r / min), heat the reactor jacket to 120°C, stir for 40 minutes after all the raw materials are dissolved Potassium carbonate was added, the temperature of the jacket of the polymerizer was raised to 200°C for 2.5 hours of reflux reaction, and trimethylbenzene and water were discharged from the water separator, and the temperature of the jacket of the polymerizer was raised to 230°C fo...

Embodiment 2

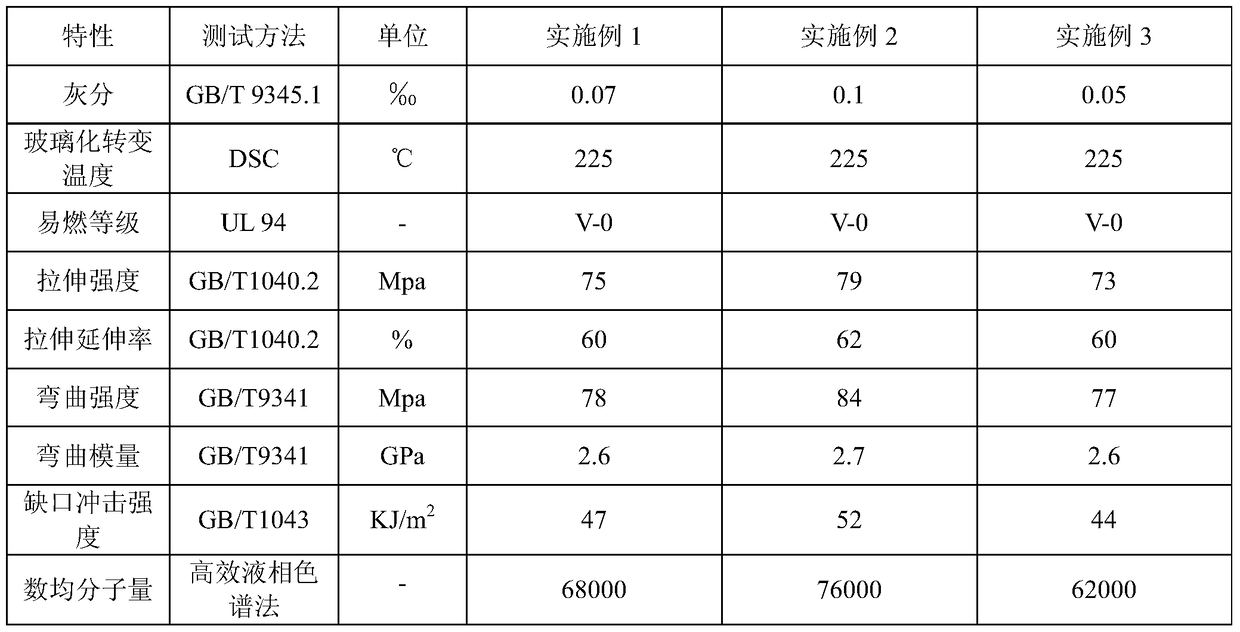

[0047] Refer to Example 1 for the specific method. The only difference from the examples is: extending the reflux reaction time by 30 minutes and the polymerization reaction time by 30 minutes; the properties of the obtained polyphenylsulfone resin are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com