Grid drive circuit with self-compensation function

A gate drive circuit and gate technology, applied in the liquid crystal field, can solve the problems of increasing the off-state leakage current of thin film transistors, and achieve the effects of saving design space, reducing overall power consumption, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

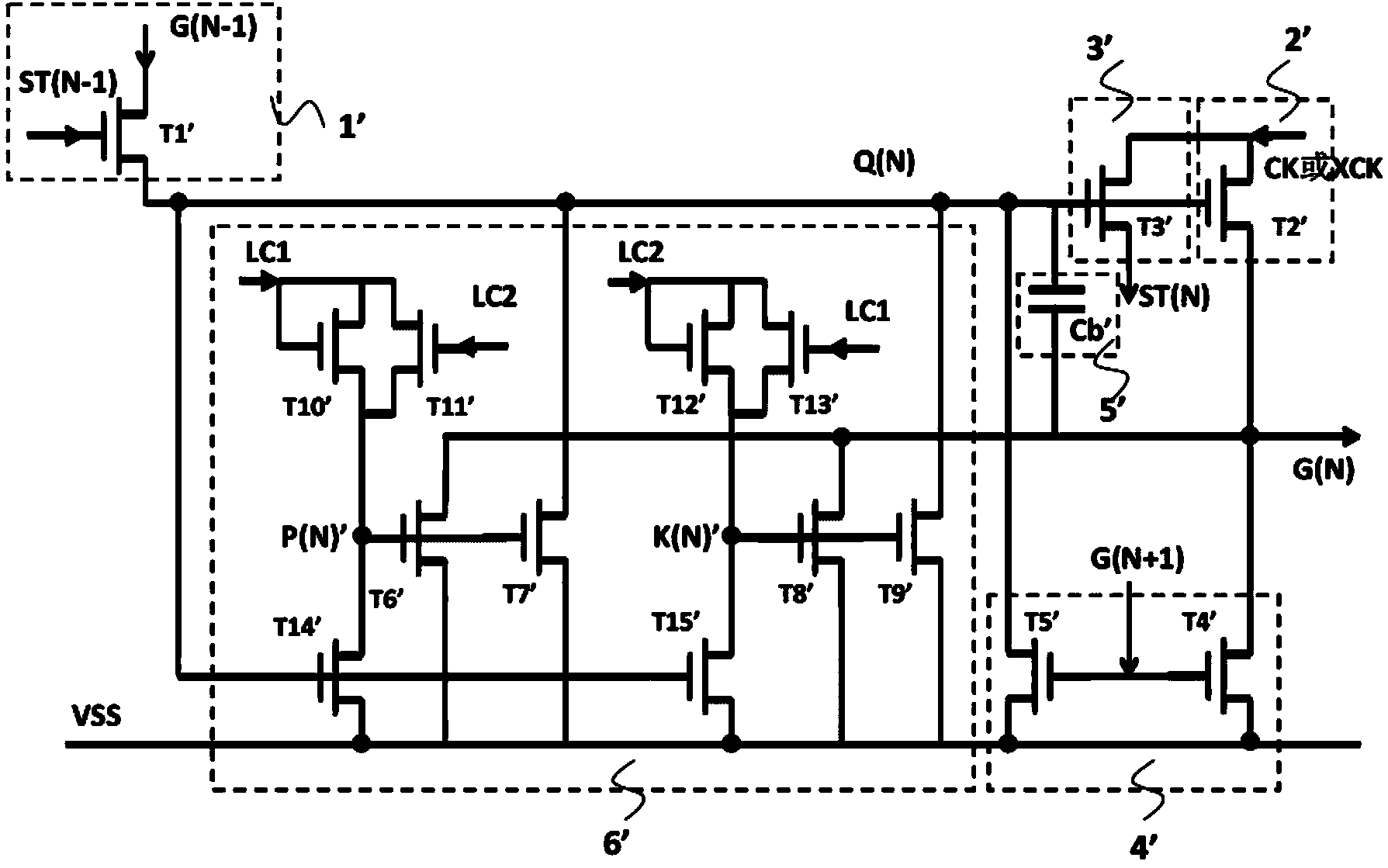

[0041] see image 3 , is a schematic diagram of a single-stage architecture of a gate drive circuit with a self-compensation function in the present invention. Including: a plurality of cascaded GOA units, charging the Nth level horizontal scan line G(N) in the display area according to the control of the Nth level GOA unit, the Nth level GOA unit includes: pull-up control module 1, pull-up module 2 , the downlink module 3, the first pull-down module 4, the bootstrap capacitor module 5, and the pull-down maintenance module 6; the pull-up module 2, the first pull-down module 4, the bootstrap capacitor module 5, and the pull-down maintenance circuit 6 are respectively It is electrically connected to the Nth level gate signal point Q(N) and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com