Air cylinder sleeve clamp

A cylinder liner and fixture technology, which is applied in the field of cylinder liner fixtures, can solve problems such as poor positioning reliability, affecting machining accuracy, and surface quality problems, and achieve high positioning accuracy, good clamping reliability, and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

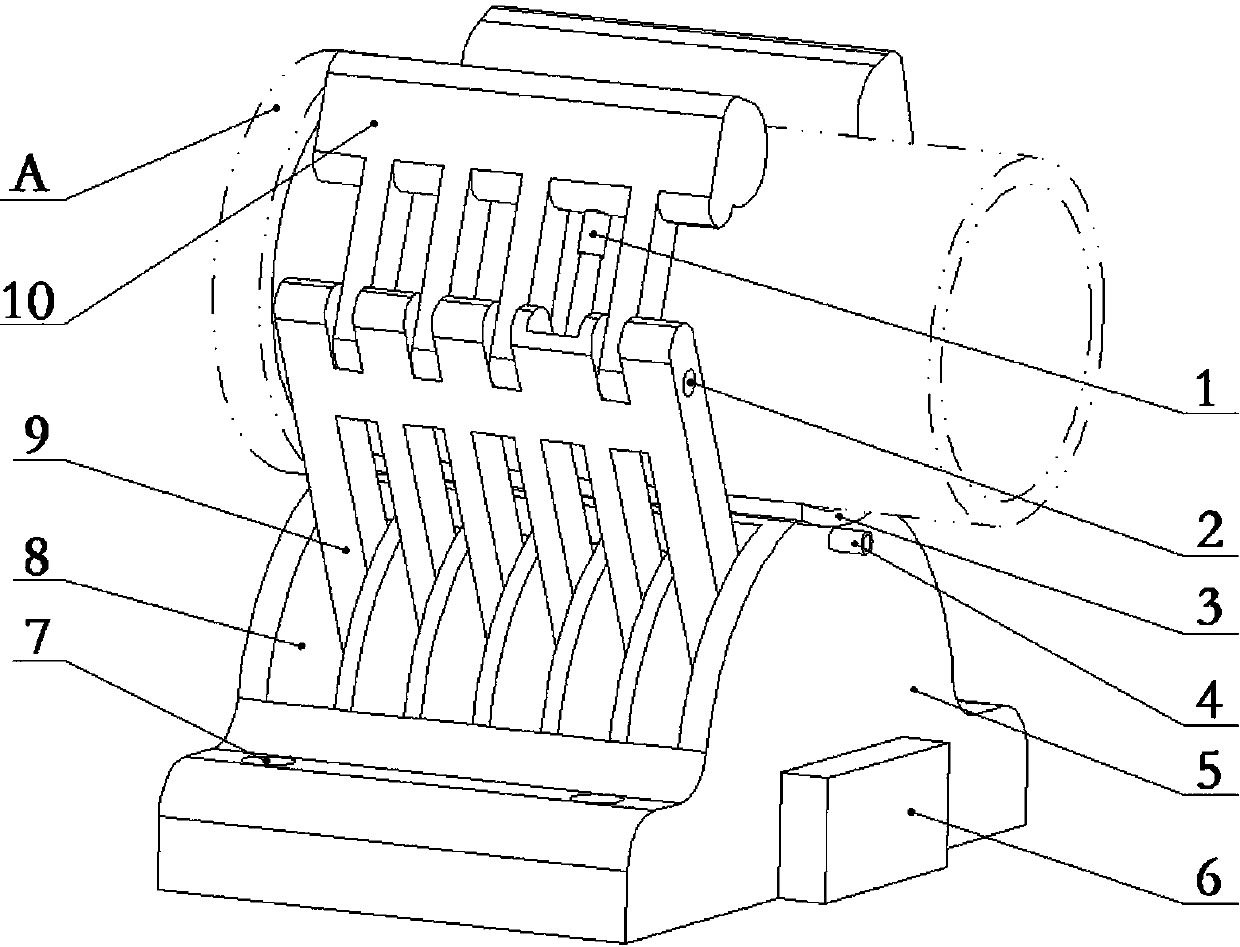

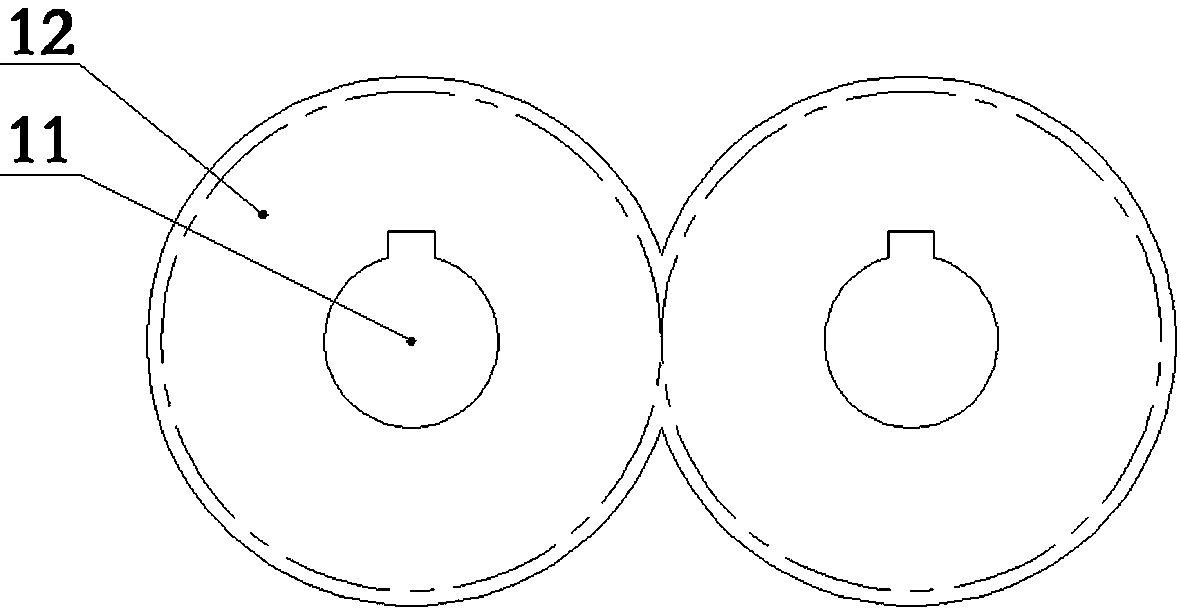

[0035] Refer to the attached figure 1 A cylinder liner clamp, in the figure, is a cylinder liner clamp in which the cylinder liner A to be positioned is clamped horizontally, but it can also be laid down to clamp the cylinder liner A in the vertical direction.

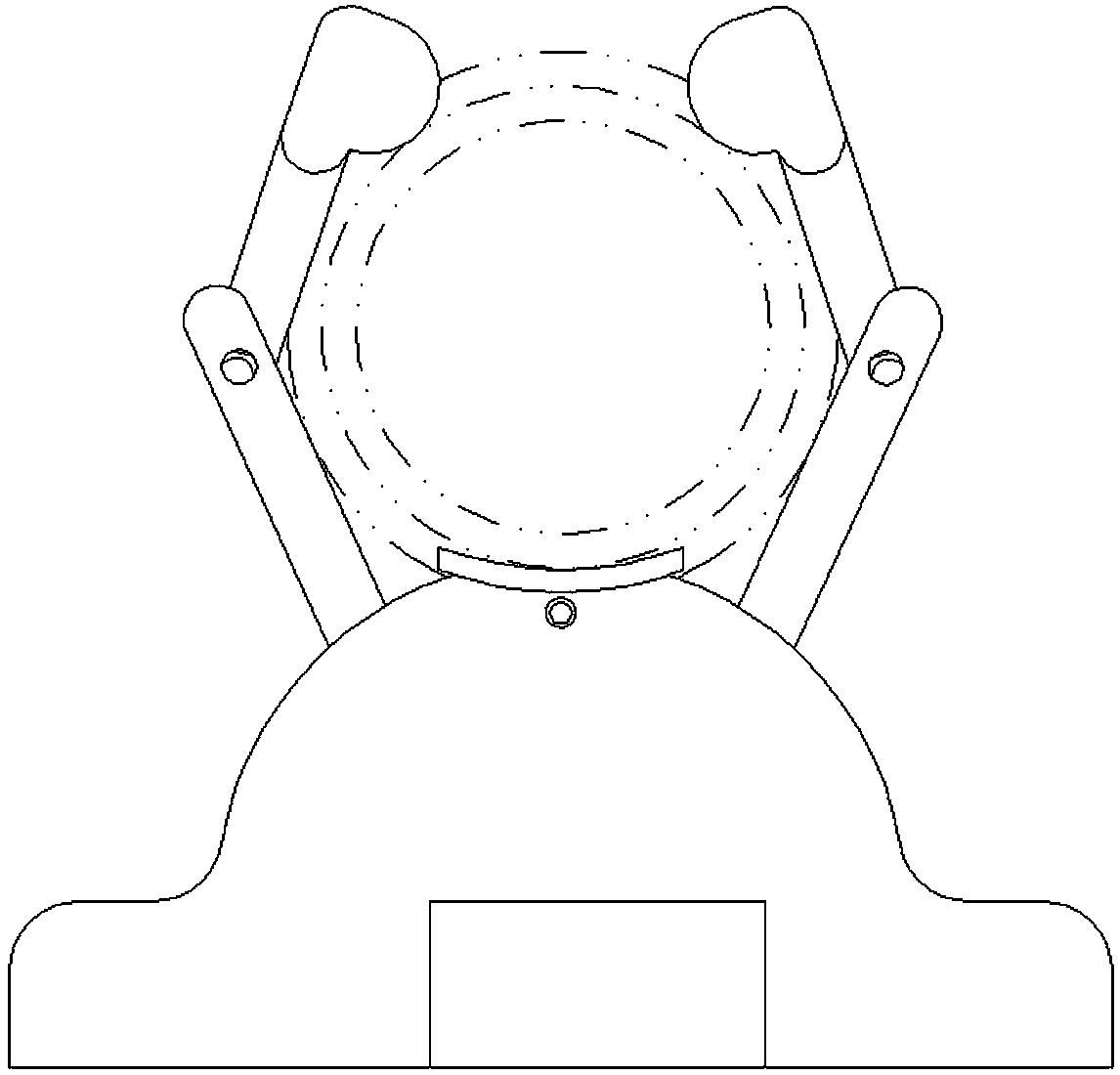

[0036] From figure 2 It can be seen from the figure that the cylinder liner fixture as a whole is a plane-symmetric structure, and the corresponding plane of symmetry is in figure 2 Middle is the vertical plane passing the axis of cylinder liner A.

[0037] Furthermore, in figure 1 Among them, the base 5 of the cylinder liner fixture is a plane-symmetrical structure about a given symmetrical plane. The symmetrical plane in the figure is a vertical plane. The top of the base 5 provides an initial support structure, so that the workpiece, that is, the cylinder Sleeve A is placed on the initial support structure before it is clamped.

[0038] Correspondingly, the initial support structure is also symmetrical about t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com