Multi-point drive belt conveyor and chain tensioning method for infinite car group chain

A belt conveyor, multi-point drive technology, applied in the multi-point drive endless car group chain belt conveyor and chain tensioning, continuous conveying equipment, in the field of car group chain tension, can solve the roller sag resistance It can improve the carrying capacity, enhance the reliability of work, and reduce the deviation of the belt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

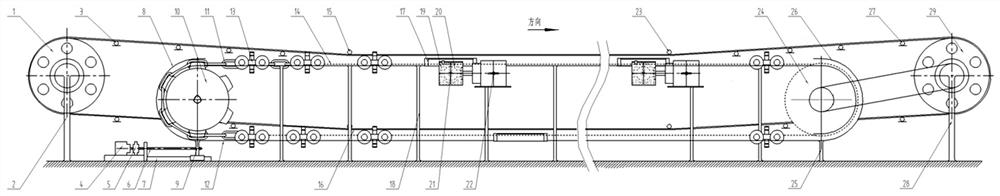

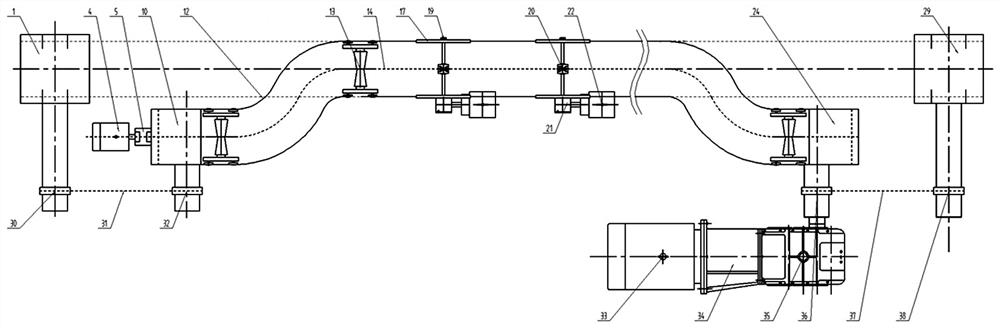

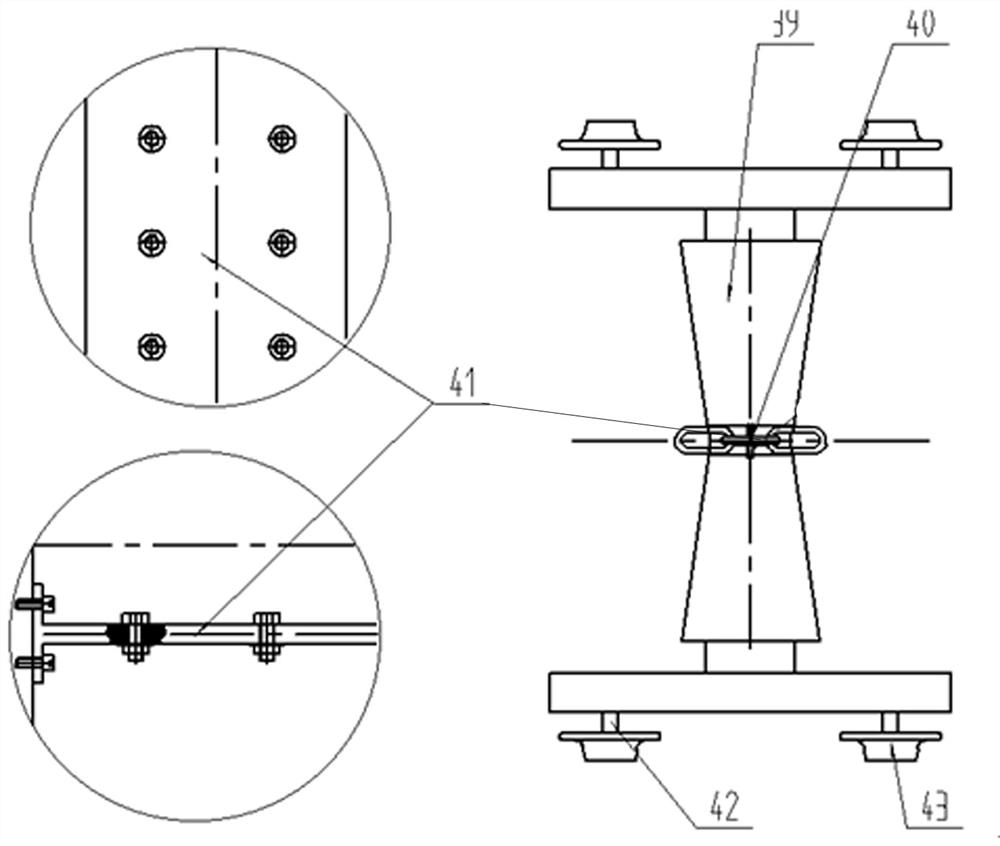

[0034]The belt conveyor chain tensioning method of the present invention is that the conveyor belt of the conveyor is driven by a non-polar closed ring train chain, and the train chain is driven by a multi-point sprocket to reduce the maximum tension of the chain, and the train chain is driven by a multi-point sprocket. The chain adopts a segmented tensioning method to ensure the tension of each chain segment of the train chain. Compared with the tensioning of the conveyor belt in the general-purpose belt conveyor, in order to realize long-distance transportation, it is difficult to realize one-time tensioning of the chain. Segmental tensioning method, segmental tensioning can realize the sequential tensioning of the circular link chain from the nose to the tail, and all the surplus is driven by the motor and reducer at the fixed position of the tail to drive the lead screw, and the lead screw drives the tail rail frame The sprocket and the tail rail move horizontally along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com