Patents

Literature

42results about How to "Low lubrication requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

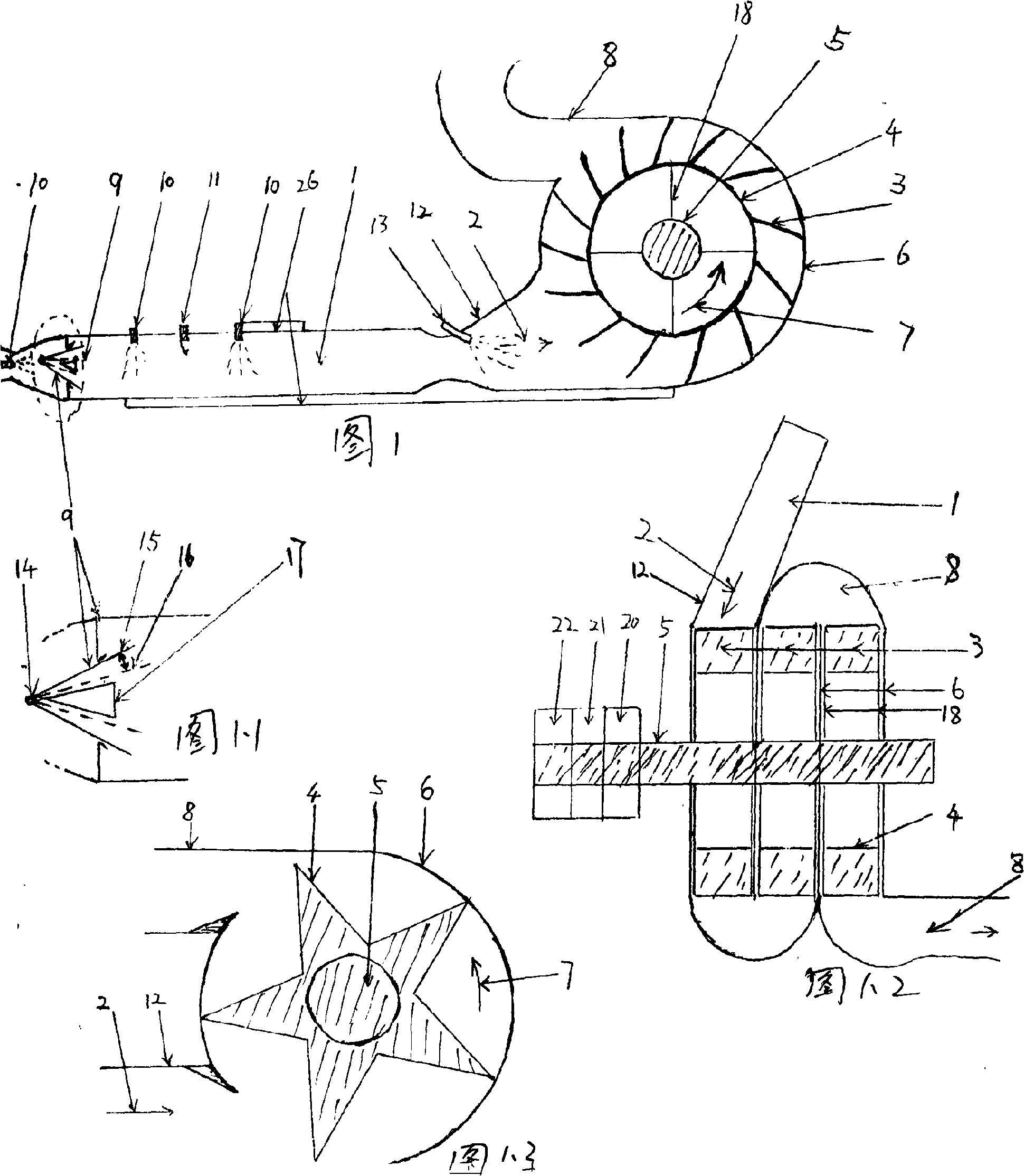

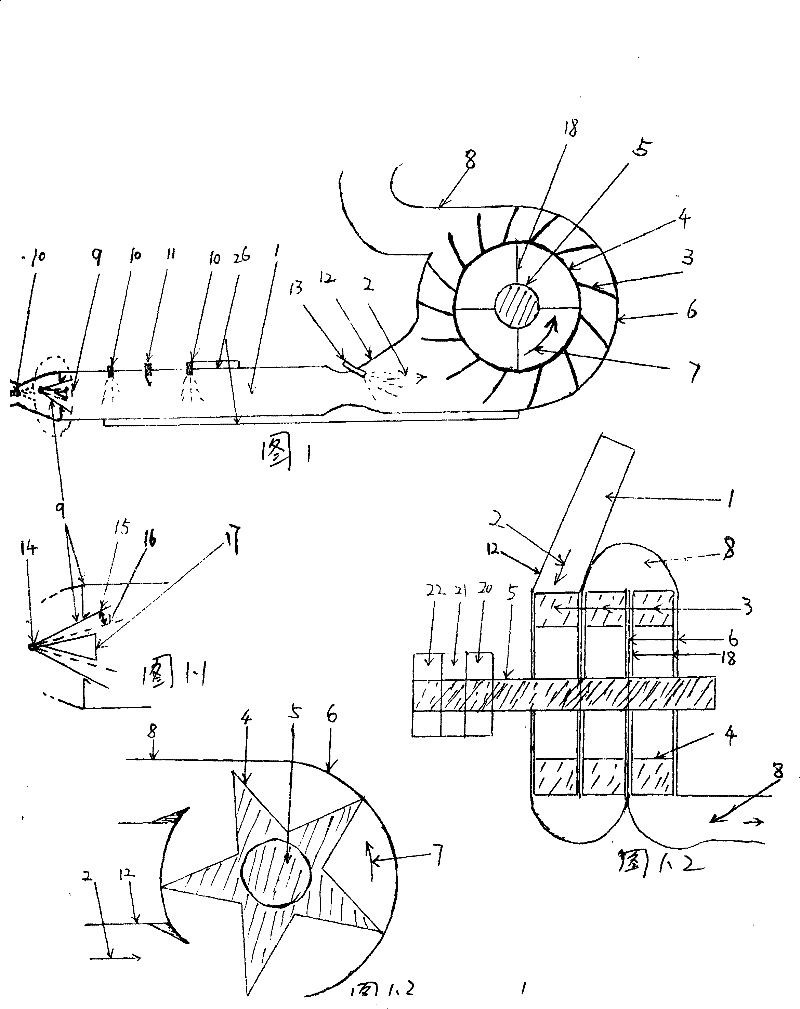

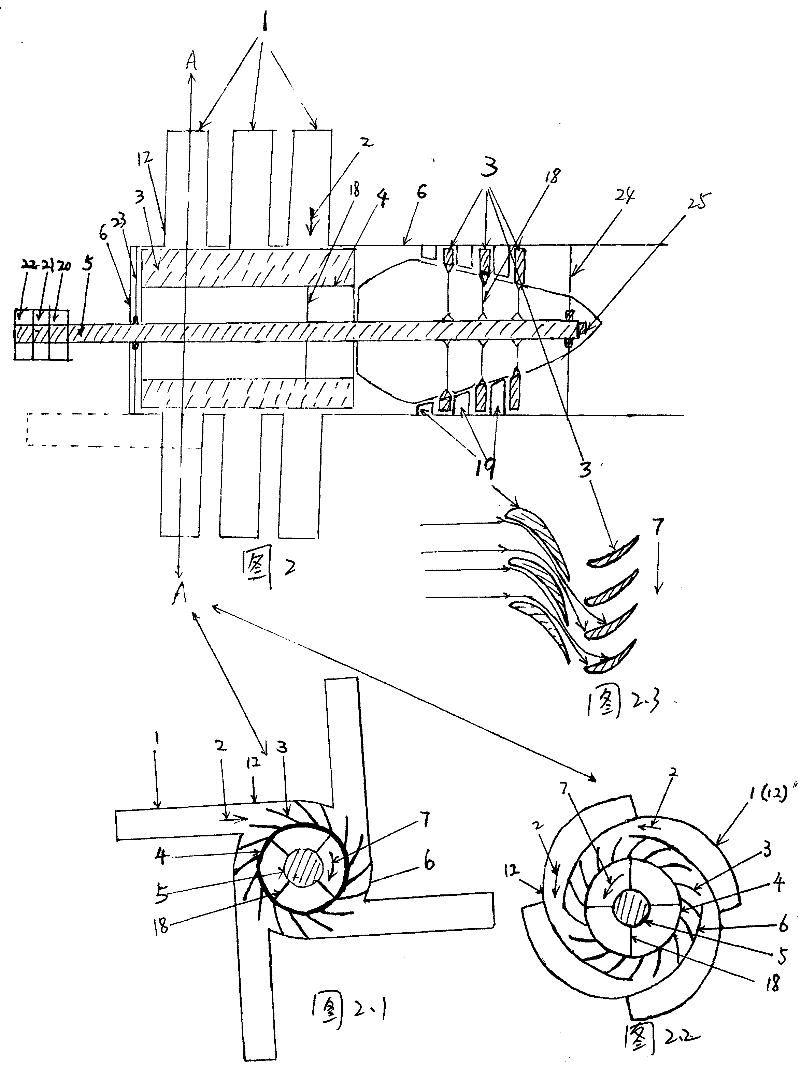

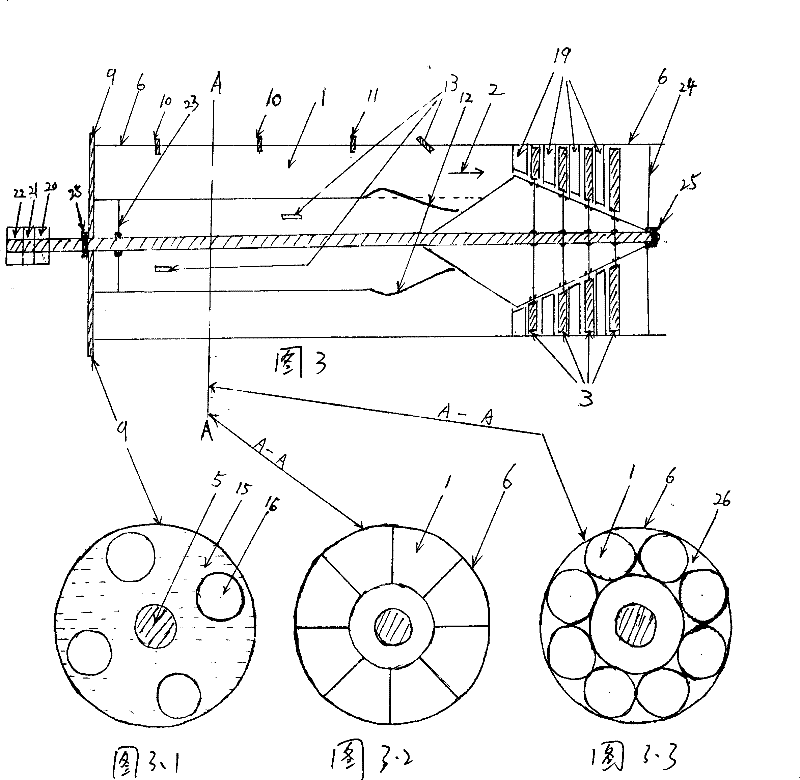

Pulse knock rotor spindle engine

InactiveCN101338702AIncrease useSingle purposeTurbine/propulsion engine coolingGas turbine plantsHigh pressureSubmarine

The present invention relates to a pulse detonation rotor shaft engine. In the technical proposal, the pulse detonation rotor shaft engine mainly consists of a pulse detonation engine, a rotor and an output shaft; propulsive gas with the high temperature and high pressure expansion of pulse which is ejected when the pulse detonation engine works is used as a power source to push the rotor to rotate; the rotor drives the output shaft to rotate; a pulse detonation rotor shaft engine uses the output shaft to output most energy produced by the pulse detonation engine by outputting torsion continuously; the output shaft drives various kinds of loads to work. The pulse detonation rotor shaft engine has the beneficial effects as follows: firstly, the pulse detonation rotor shaft engine can be used as a shaft engine to be widely applied in various kinds of dynamic systems, such as ship, submarine, tank, tractor, automobile, train, and the like and has wide purposes; secondly, the pulse detonation rotor shaft engine overcomes the disadvantage of the large noise of the prior pulse detonation engine; thirdly, compared with a piston type engine, the pulse detonation rotor shaft engine has the obvious advantages of simple structure, low cost, high reliability, long service life, light weight, less fraction resistance loss, etc.

Owner:RUGAO HUAYANG ALUMINUM PROD

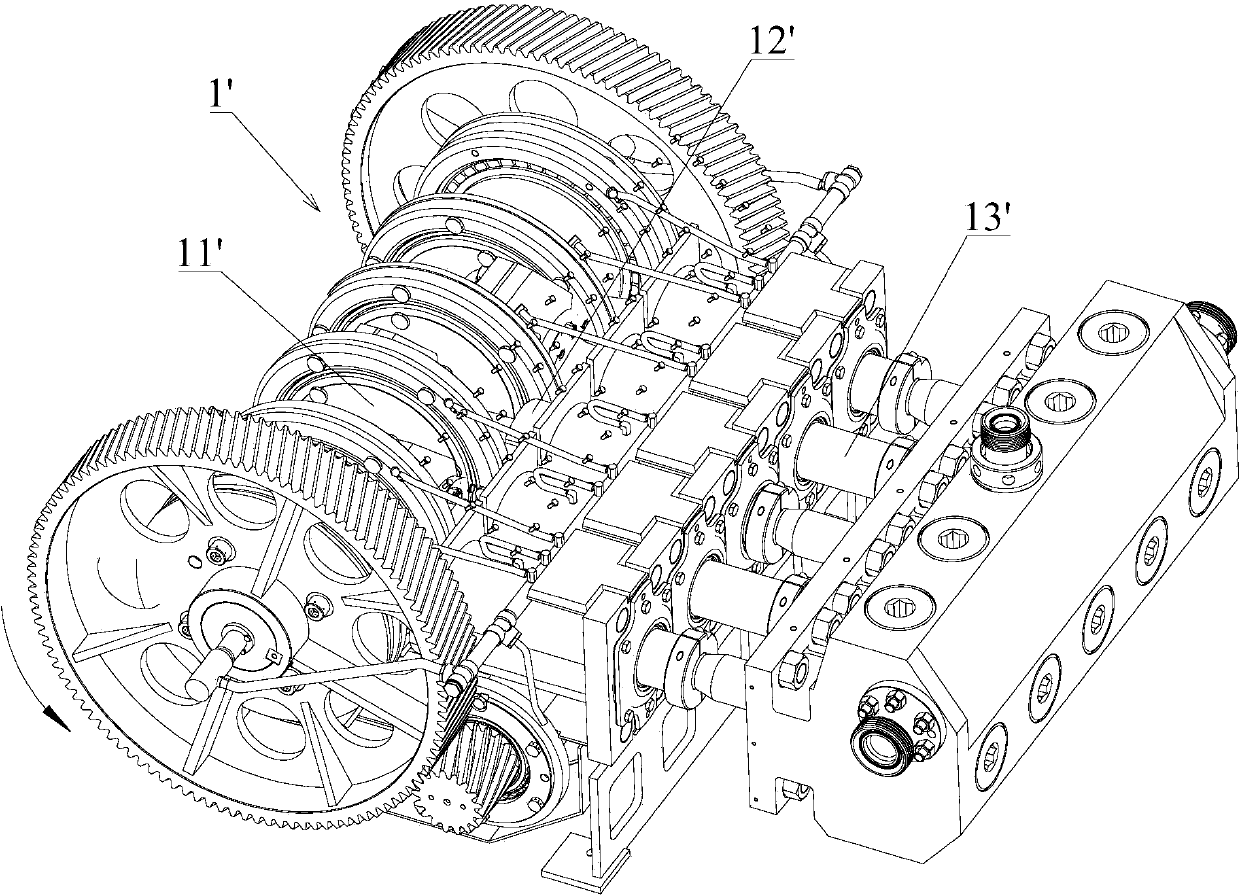

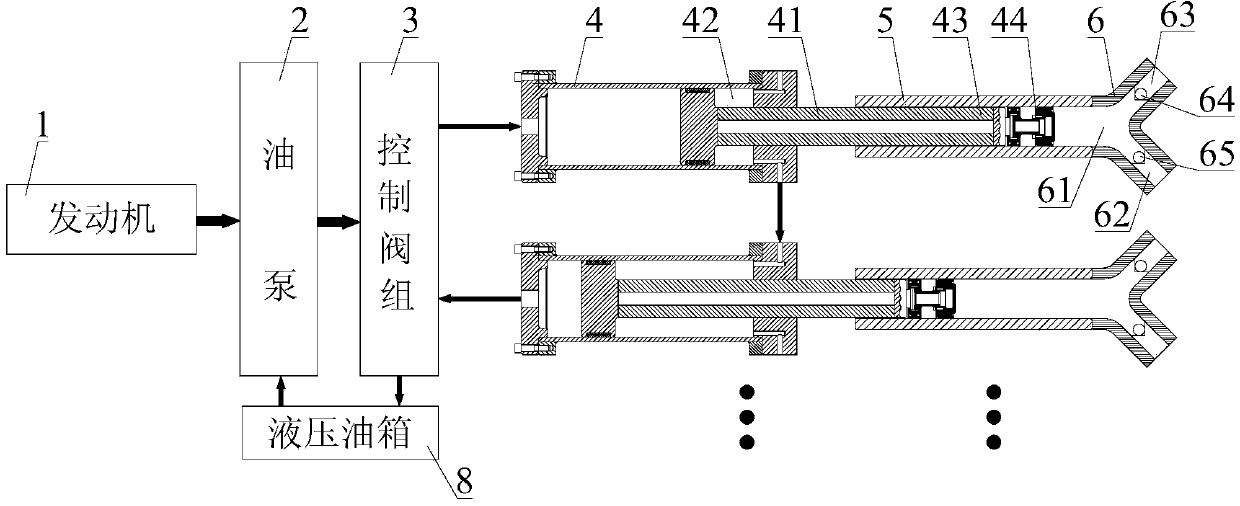

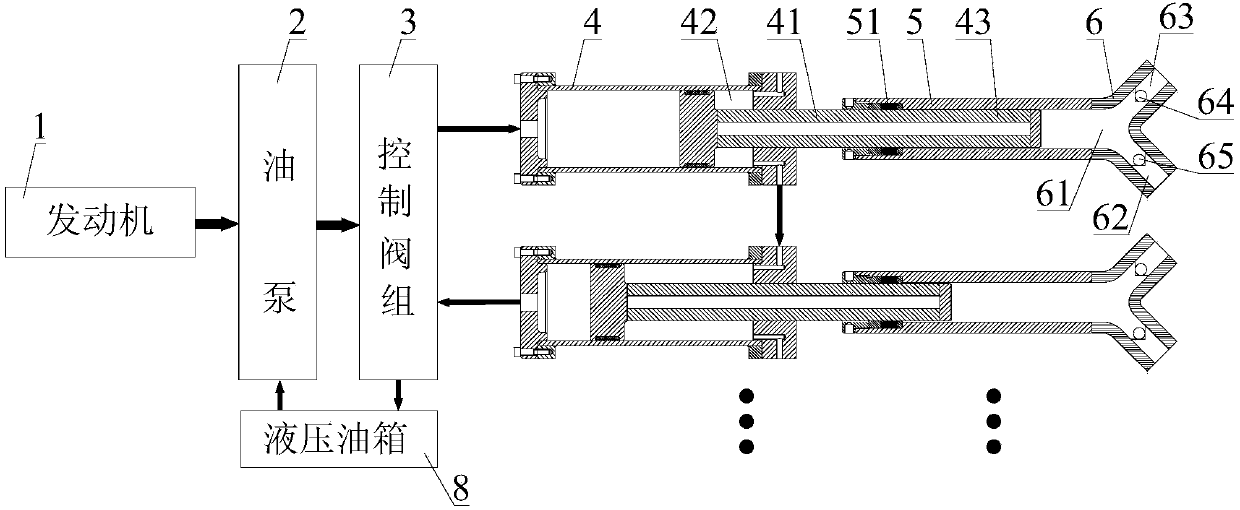

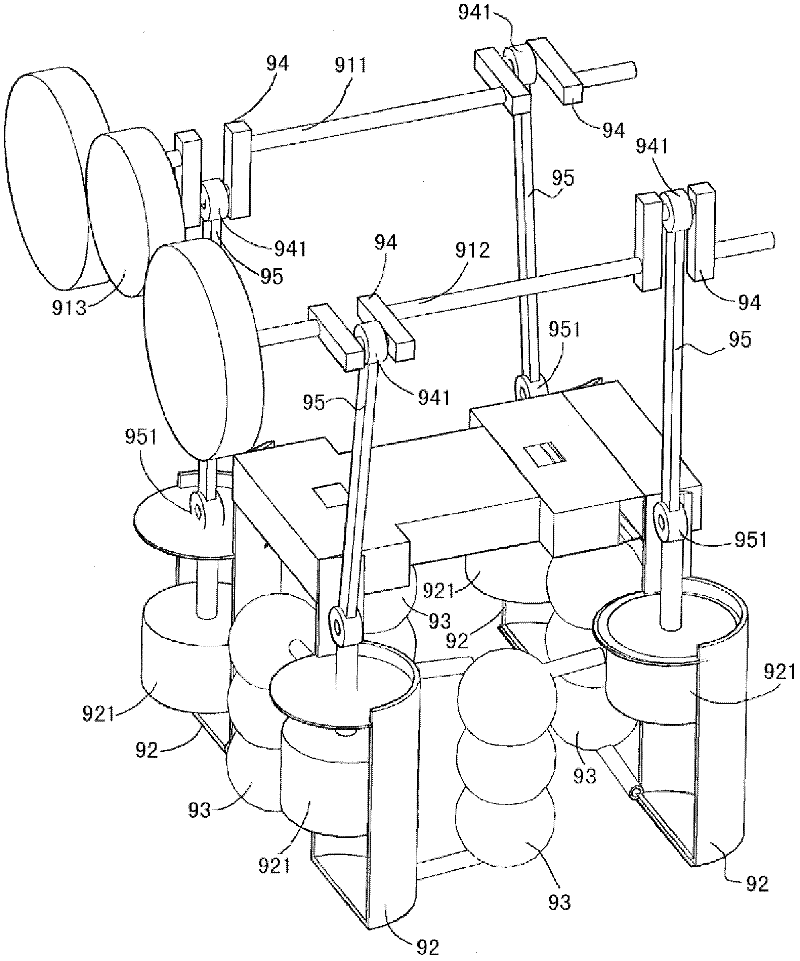

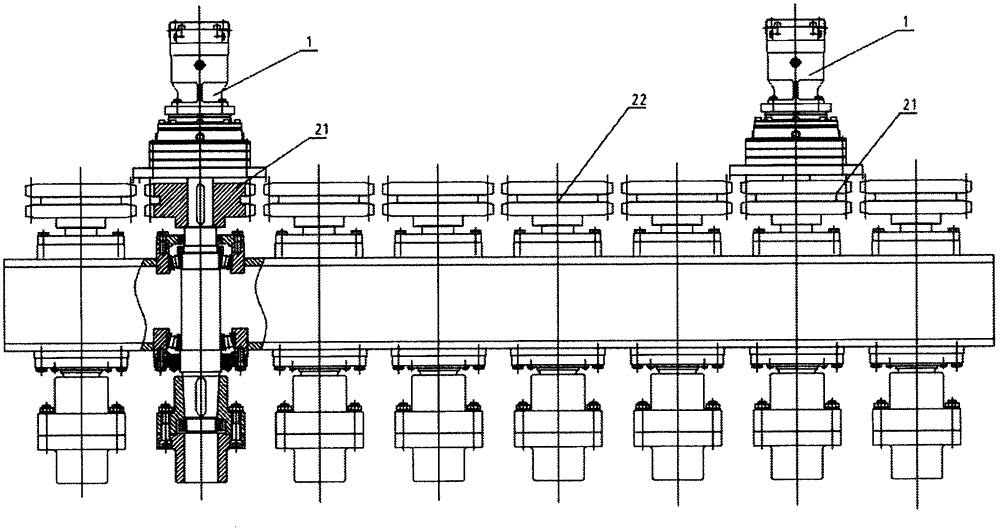

Fracturing pump system and fracturing truck

ActiveCN103742381AFlexible arrangementSimple structureFluid removalPiston pumpsEngineeringControl valves

The invention discloses a fracturing pump system and a fracturing truck. In the fracturing pump system, a first conveying mechanism and a second conveying mechanism comprise oil cylinders, supercharging cylinders and distribution valves. Each distribution valve comprises a first channel, a second channel and a third channel, wherein the first ends of the first channel, the second channel and the third channel are connected, a suction valve is arranged in the second channel, and a discharge valve is arranged in the third channel. Plug bodies are arranged at the extending end of piston rods of the oil cylinders and movably arranged in the supercharging cylinders, and outlets of the supercharging cylinders are connected with the second end of the first channel. An engine is used for driving an oil pump. A control valve group is used for controlling oil inlet and return states of the oil cylinders. By using the fracturing pump system, a stroke can be effectively increased, stoke times can be decreased, the service life of easily damaged parts can be prolonged, an output pressure and flow coverage range can be effectively widened, the structural complexity can be effectively reduced, the cost can be saved, and the lubrication and cooling requirements can be effectively reduced.

Owner:SANY PETROLEUM INTELLIGENT EQUIP CO LTD

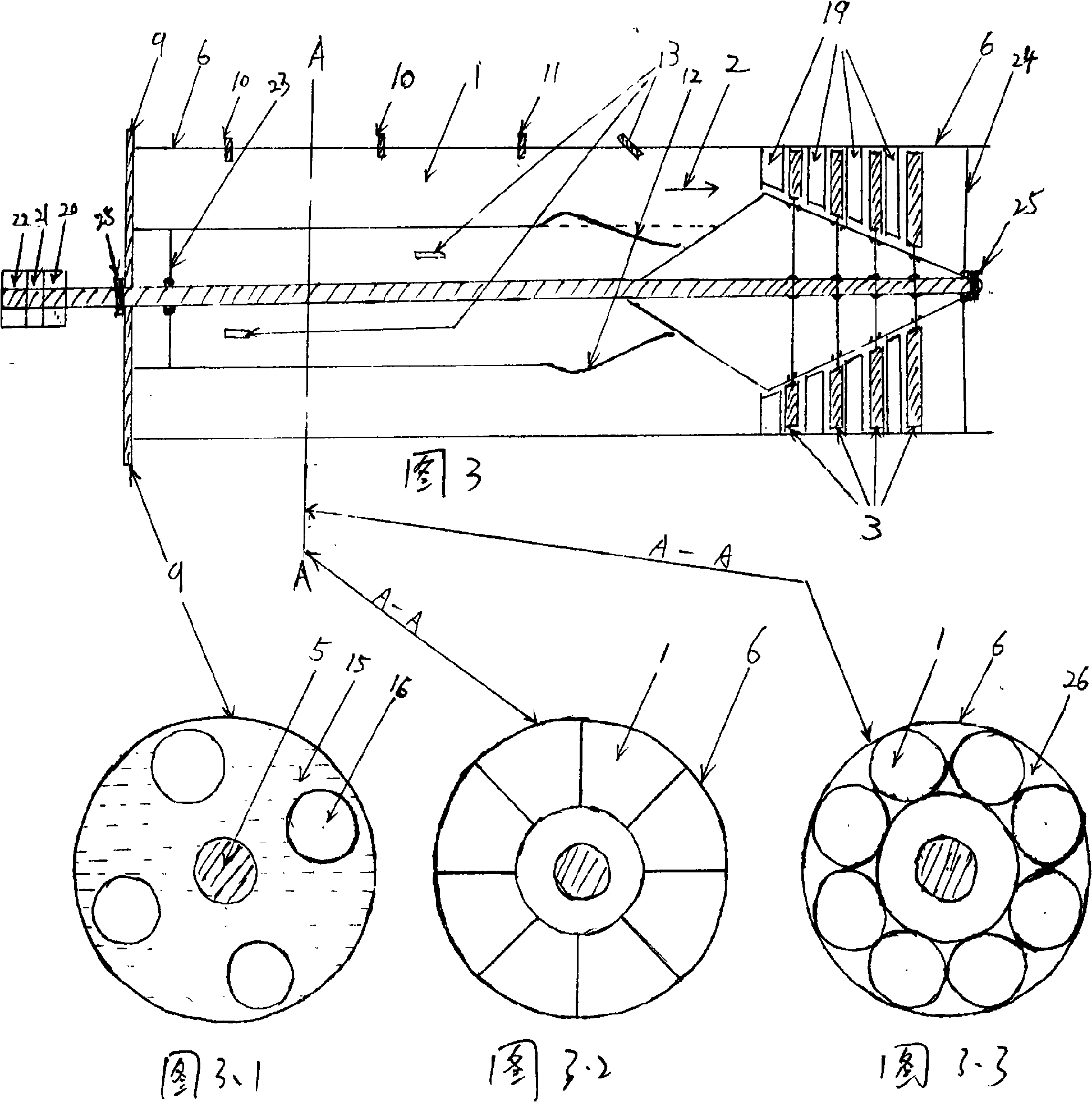

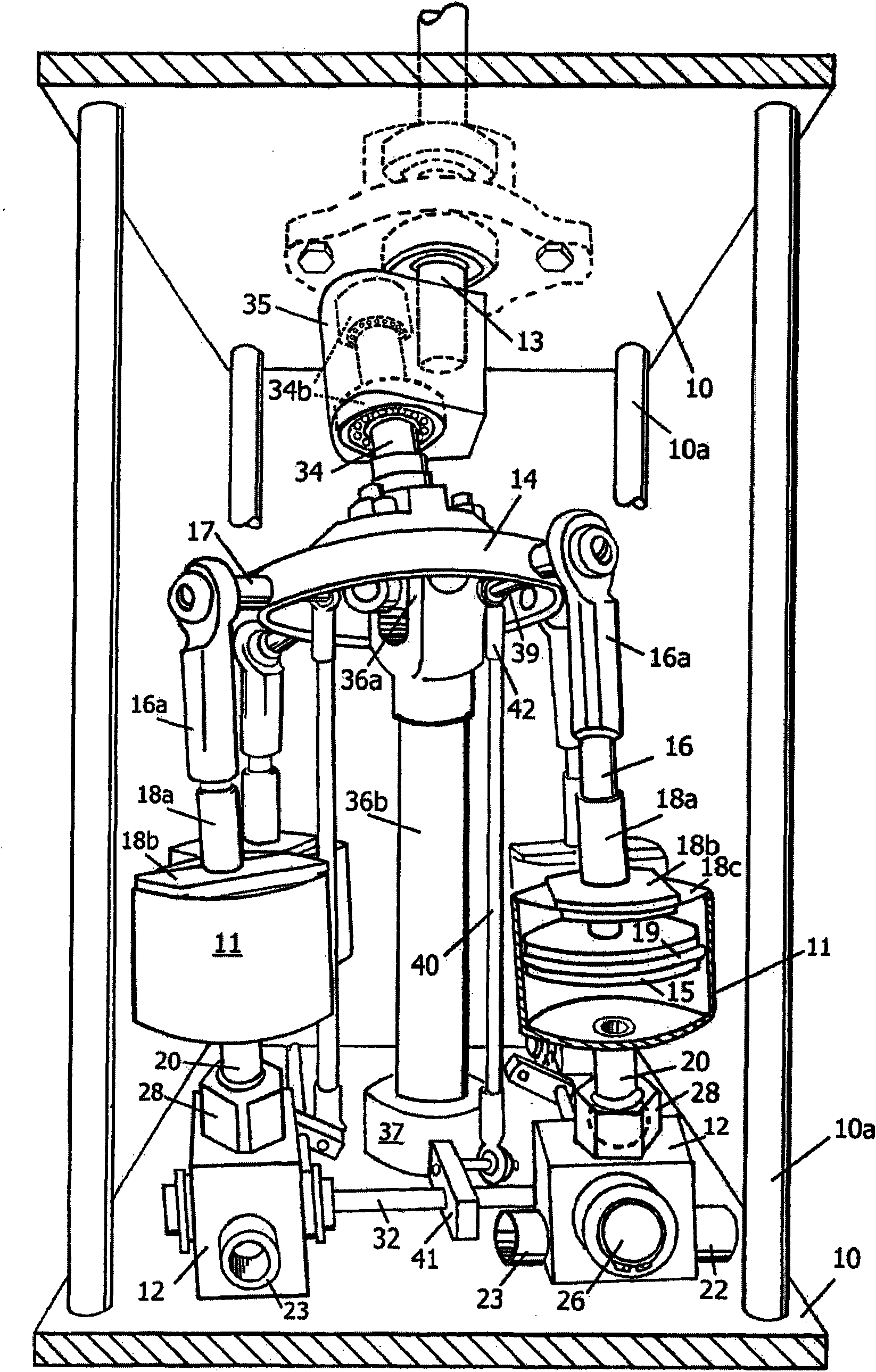

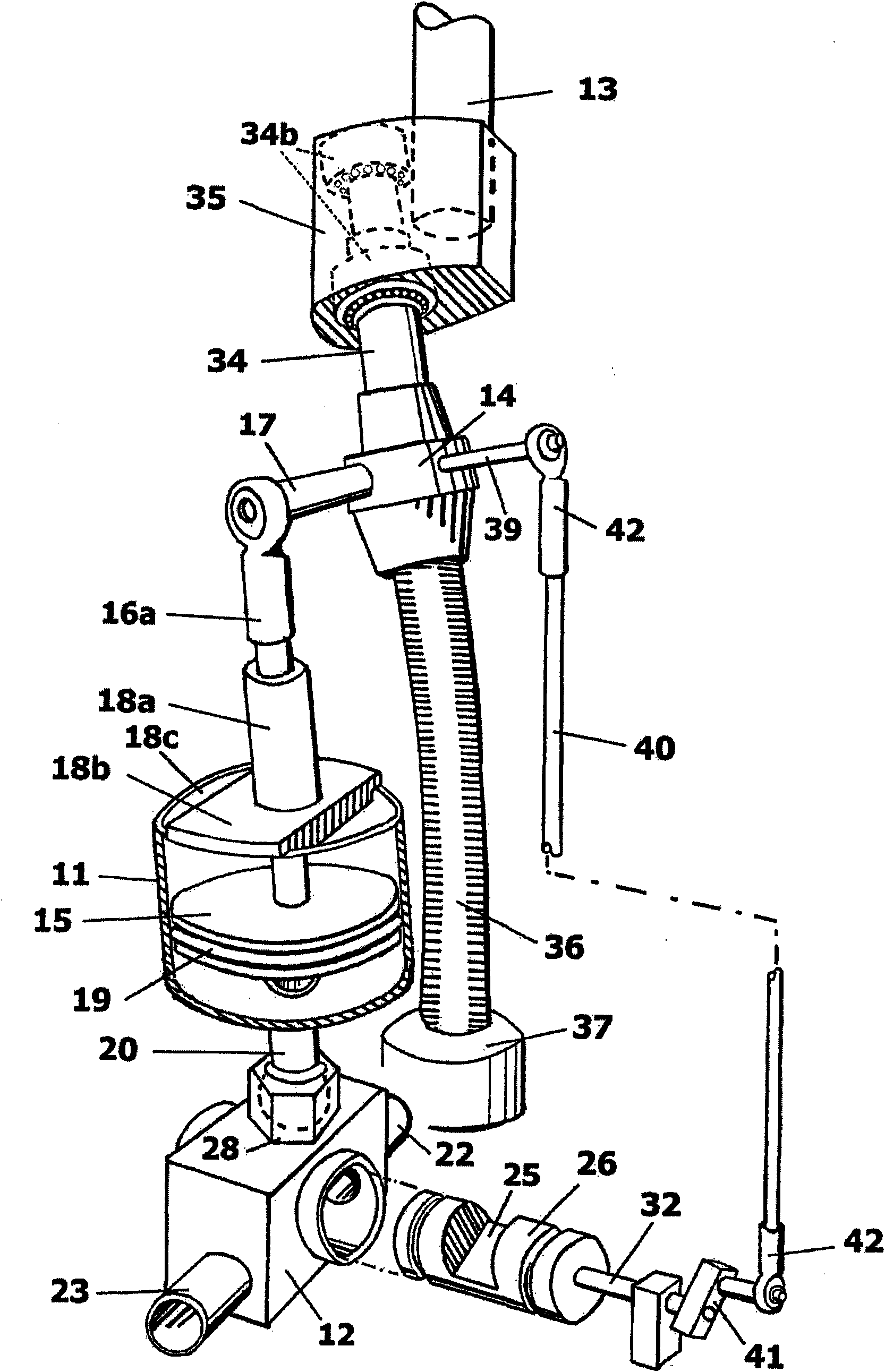

Straight-line piston fluid engine with wobble drive valve actuation

InactiveCN101910561AAchieve alignmentFacilitate communicationReciprocating piston enginesControl valvesRotation control

An axial piston fluid engine having single-acting cylinders 11 incorporating swivel-joint attachment 28 of the cylinders to rotary control valves 12 wherein straight-line piston movement is established for the elimination of side forces on the pistons 15. The pistons 15 and the control valves 12 are operatively connected to a common wobble drive member 14 and arranged in geometry of lever positions to coactively time the drive fluid into and out of the cylinders intermittently.

Owner:罗伯特·格林

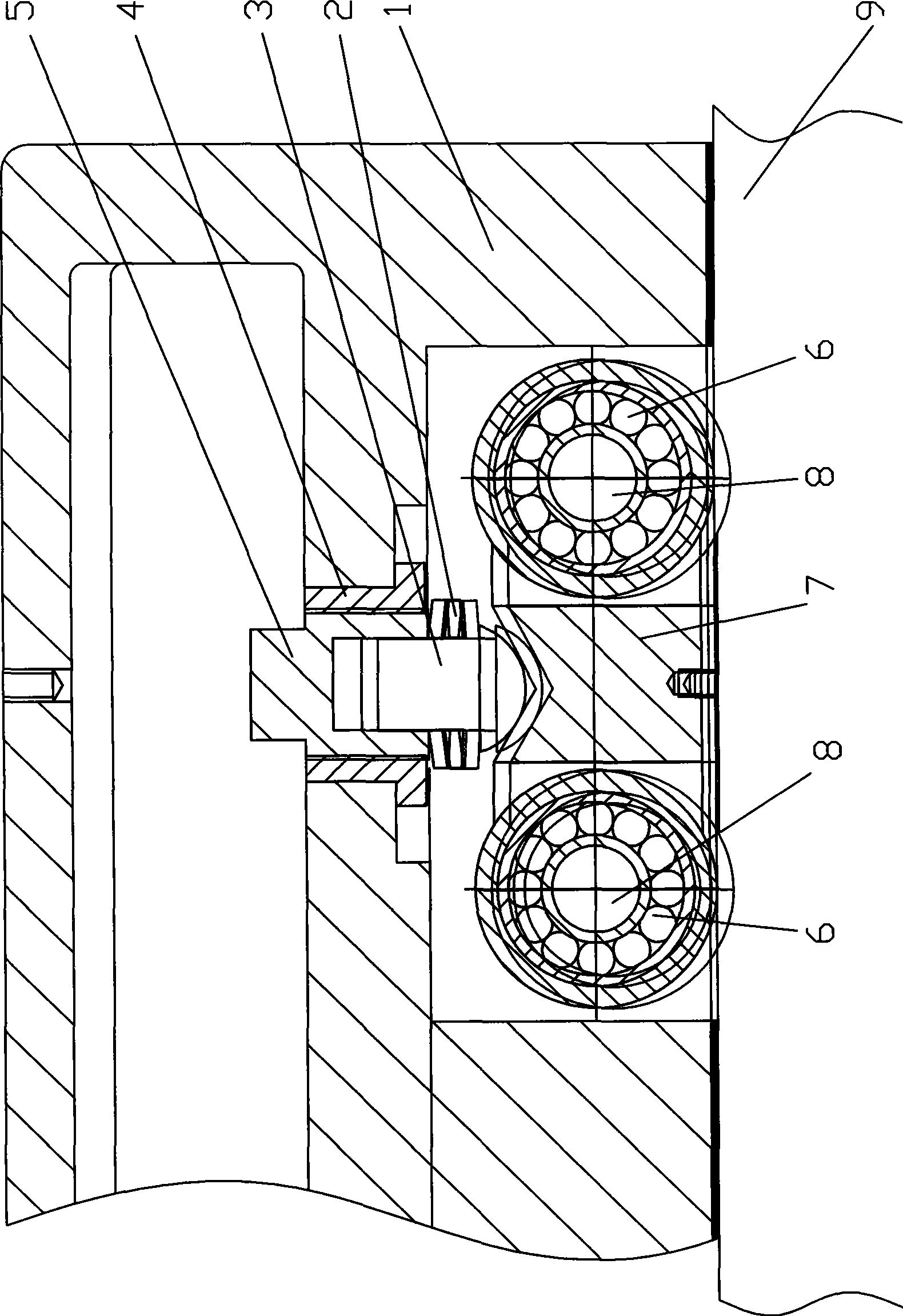

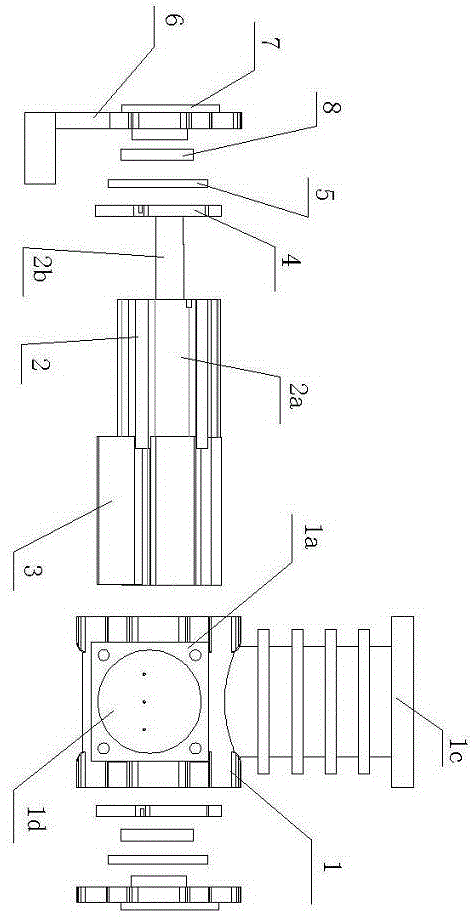

Sliding guide rolling unloading device

InactiveCN101508076AImprove contact stiffnessReduce friction areaLarge fixed membersEngineeringLubrication

The invention discloses a sliding device, in particular a slide guide rail rolling and unloading device for machine tool equipment. The device comprises a guide rail and a slide seat (1) which is positioned on the guide rail and can slide relative to the guide rail, and is characterized in that: at least three positions matched with the guide rail on the bottom surface of the slide seat (1) are provided with roller wheels (6), and the circumferential lateral surfaces of the roller wheels (6) are contacted with the upper surface of the guide rail positioned under the slide seat (1). In the device, as the slide seat and the guide rail do not directly contact, are supported by the roller wheel, and slide, the device realizes line contact of the roller wheel and the guide rail, greatly reduces the mutual friction area, reduces moving resistance, saves energy and lowers the requirement on lubrication compared with a sliding mode of surface contact.

Owner:DALIAN MACHINE TOOL GROUP CO LTD

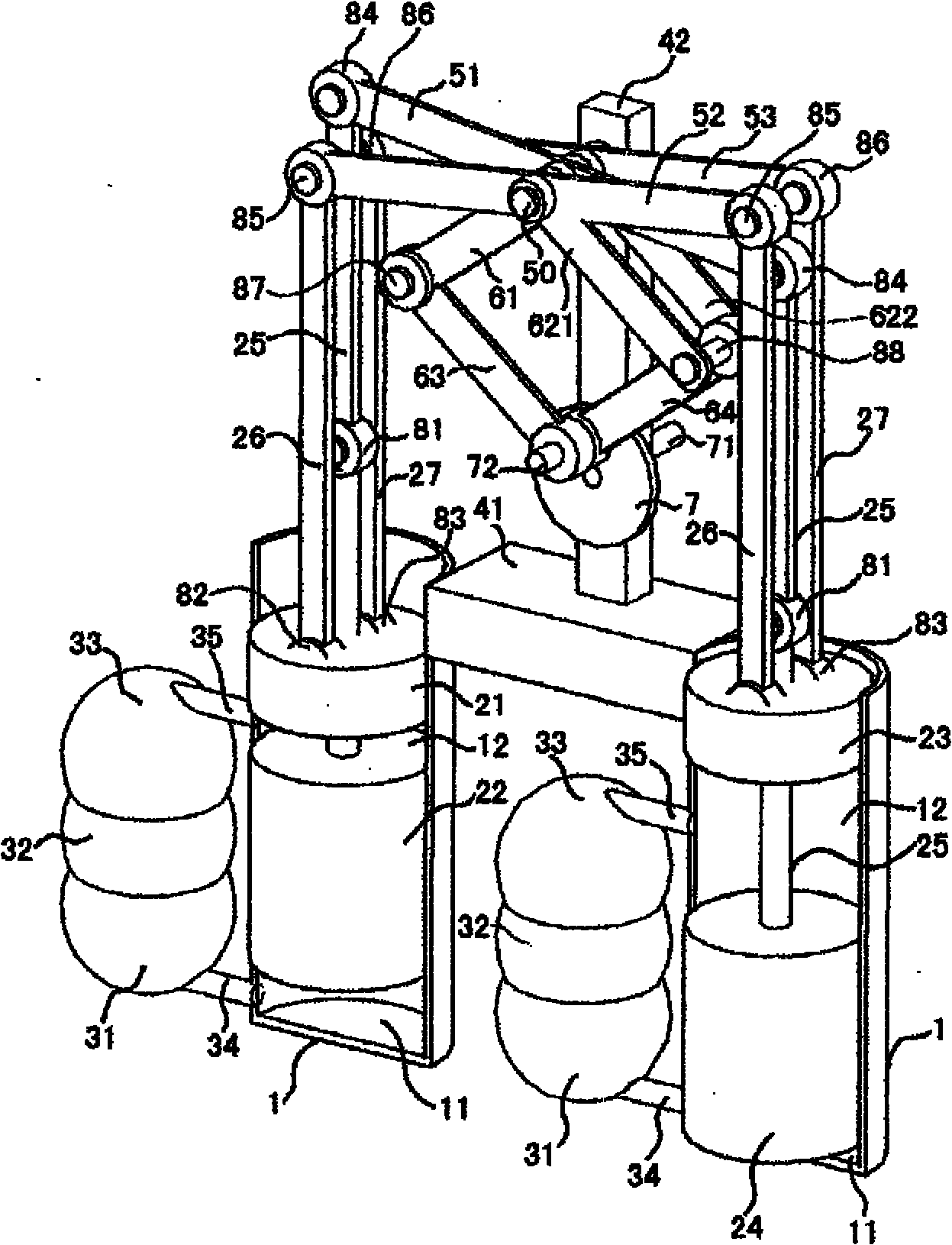

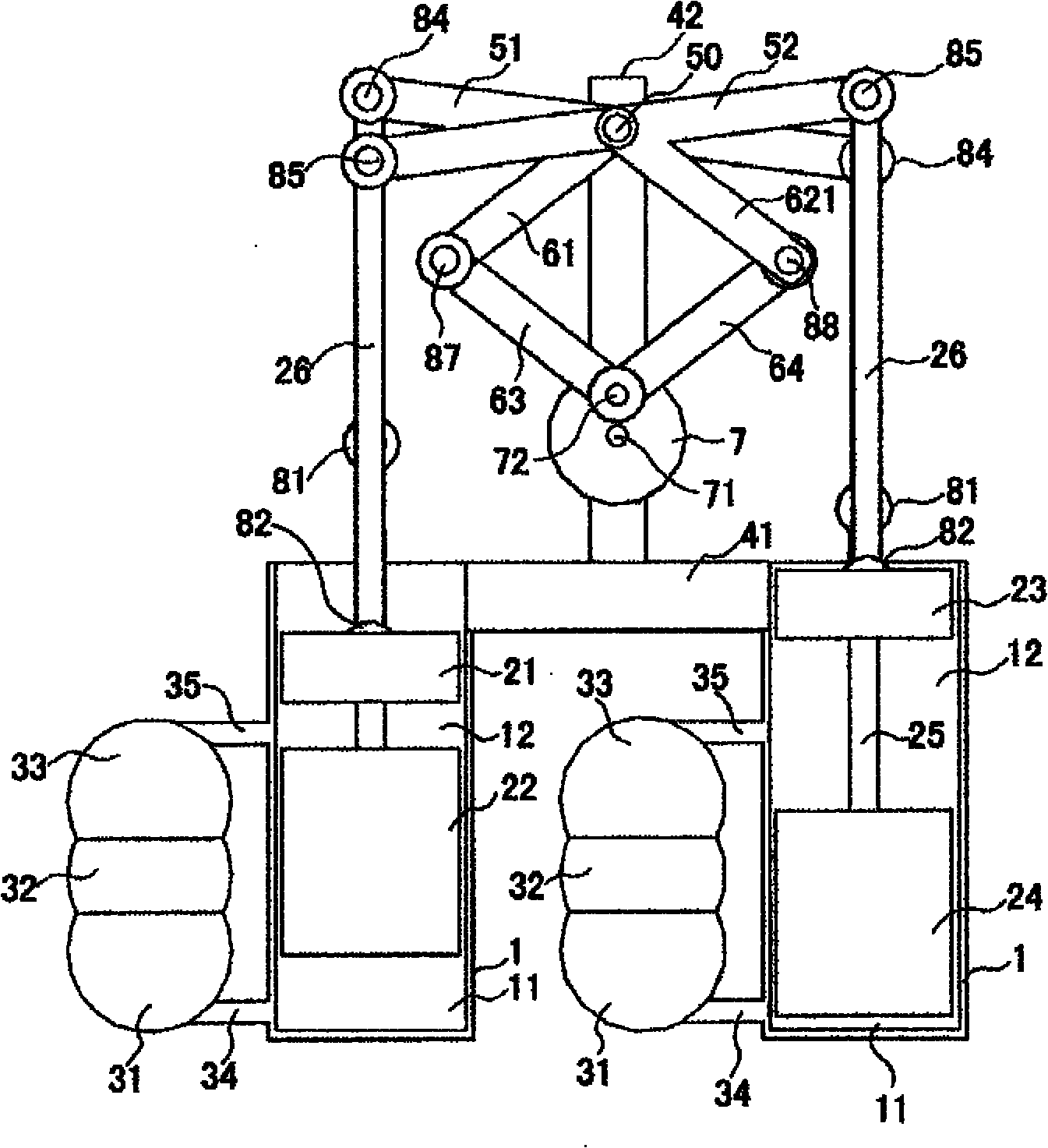

External combustion engine and transmission mechanism thereof

InactiveCN102182582AEasy to startReduce resistanceHot gas positive displacement engine plantsGas cylinderReciprocating motion

The invention discloses an external combustion engine and a transmission mechanism thereof. The external combustion engine comprises two groups of hot gas components, a transmission mechanism and a crank shaft, wherein each group of the hot gas components comprises a gas cylinder, a heater, a reheater and a cooler; a power piston replacement piston is arranged in the gas cylinder, and a cold cavity and a hot cavity are formed in the gas cylinder; the transmission mechanism comprises a connecting rod group and a swing rod group; the swing rod group comprises a center swing rod and edge swing rods; piston rods are hinged at two ends of the swing rod group respectively; a plane on which the center swing rod is placed and the planes on which the edge swing rods are placed are parallel to each other and coaxial with each other on a pivot shaft; the connecting rod group is surrounded by four connecting rods which are hinged between the pivot shaft and a crank shaft connecting rod neck; the first connecting rod and the second connecting rod are as long as each other and keep complementary angles from 30 to 60 degrees with the center swing rod and the edge swing rods; the third connecting rod and the fourth connecting rod are as long as each other, and the upper ends of the third connecting rod and the fourth connecting rod are hinged with each other; and a heat source heats the heater so that gas in a gas channel is expanded and contracted due to a reciprocating motion between a cold cavity and a hot cavity, and the crank shaft is driven by the transmission mechanism to do a periodic motion and work. The external combustion engine is easy to start and has low cost.

Owner:杨永顺

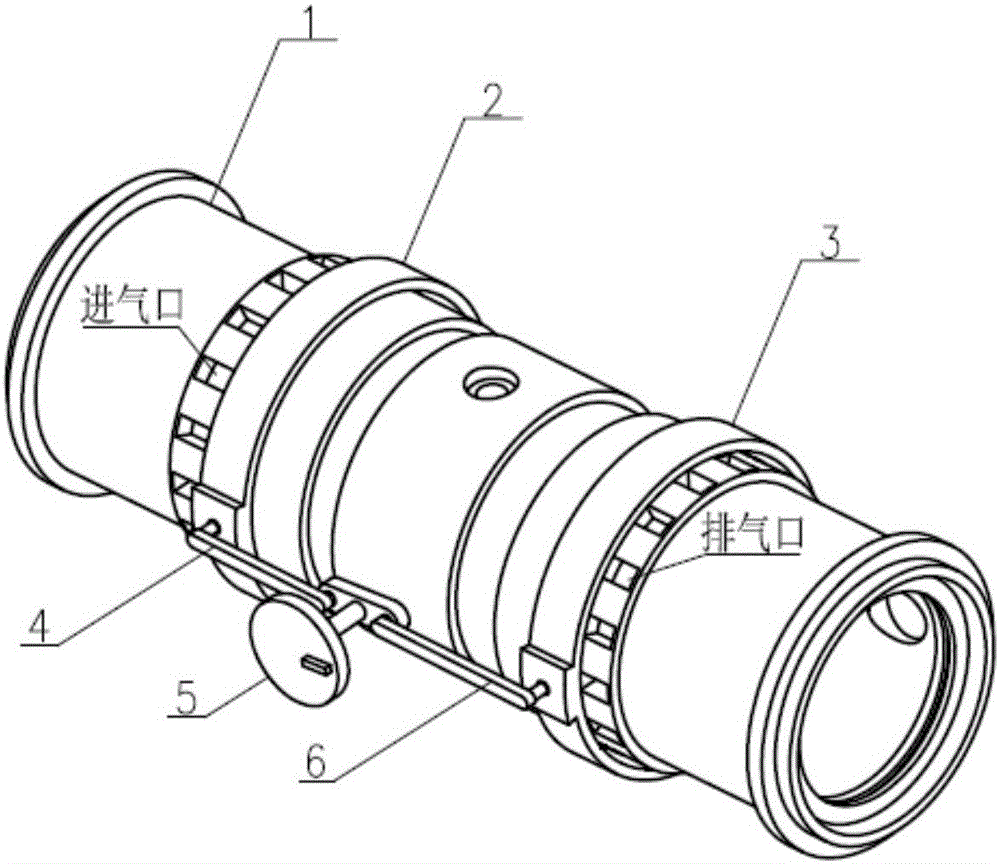

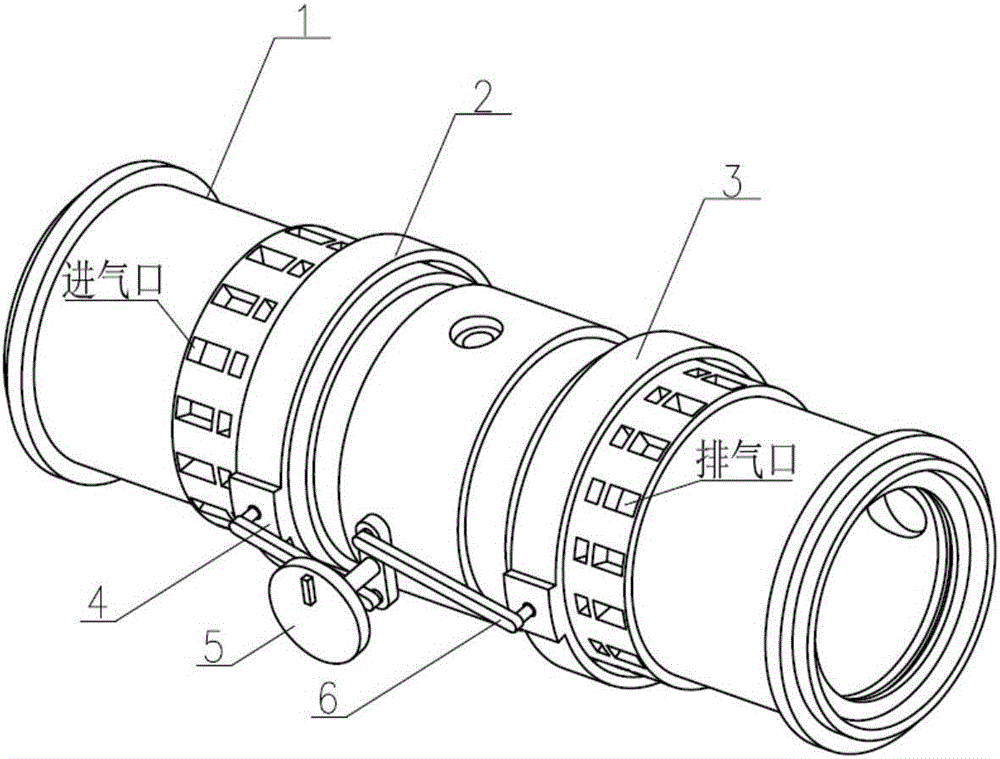

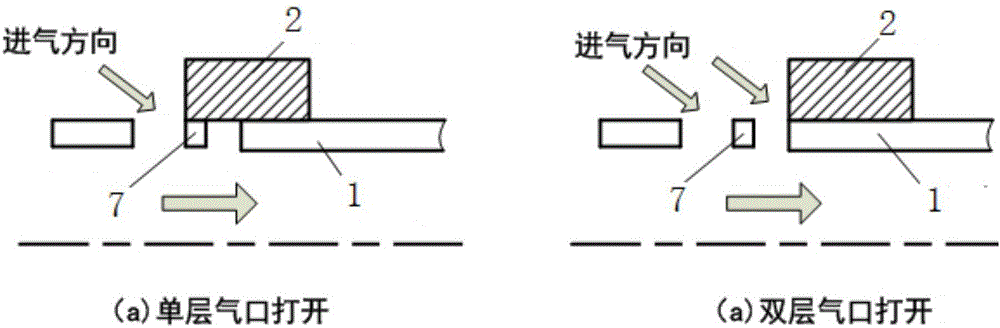

Variable gas distribution phase mechanism for opposed-piston engine

ActiveCN106837457AOptimized ventilation and combustion processImprove performanceValve arrangementsCylinder headsFree-piston engineEngineering

The invention discloses a variable gas distribution phase mechanism for an opposed-piston engine, and belongs to the technical field of internal combustion engine structures. The variable gas distribution phase mechanism comprises an air cylinder sleeve, an air inlet slide sleeve, an air outlet slide sleeve, an air inlet connecting rod, an air outlet connecting rod and an adjustable crank, wherein the air cylinder sleeve is provided with a plurality of layers of air ports; the number of the air port layers on the air cylinder sleeve corresponds to the relevant engine rotation speed, namely the air port adjusting type is adjusted by different shifts. The variable gas distribution phase mechanism consists of two crank slide block mechanisms in series; the adjustable crank is adjusted to drive the slide sleeves to move under the actions of the air inlet connecting rod and the air outlet connecting rod, so as to switch the number of air port layers in different shifts. The variable gas distribution phase mechanism has the advantages that the average effective pressure and the gas changing characteristic of the opposed-piston engine can reach the optimum state under various working conditions; the cost is reduced, and the system reliability is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

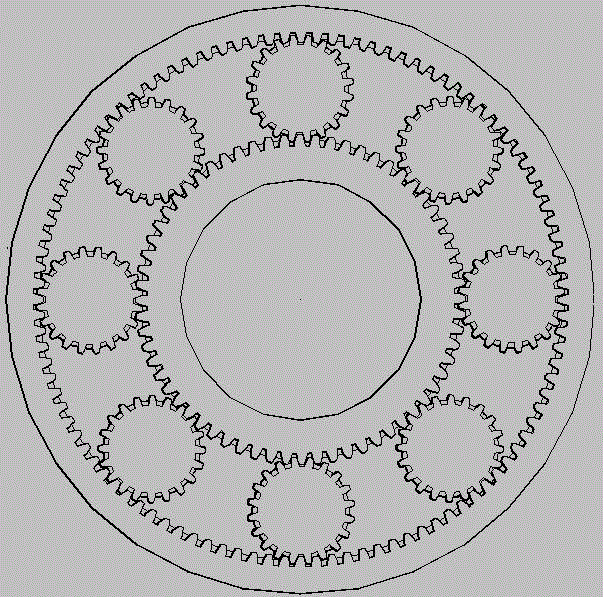

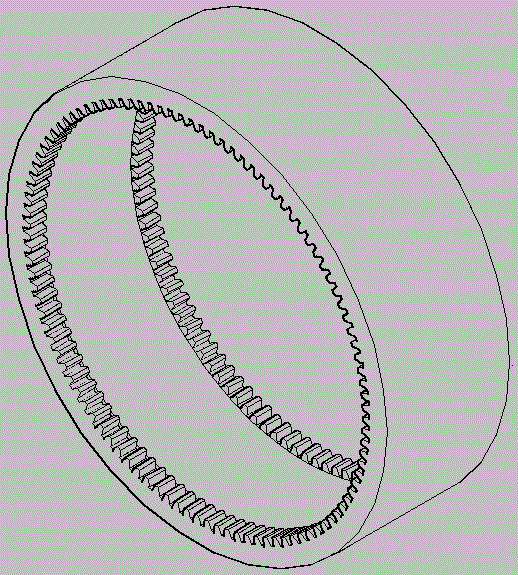

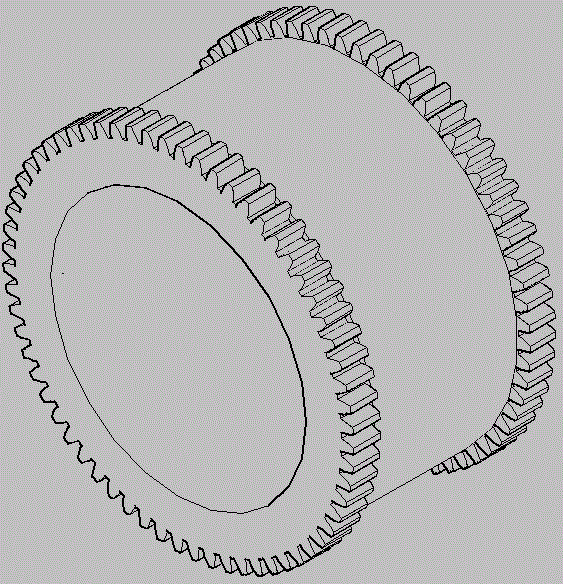

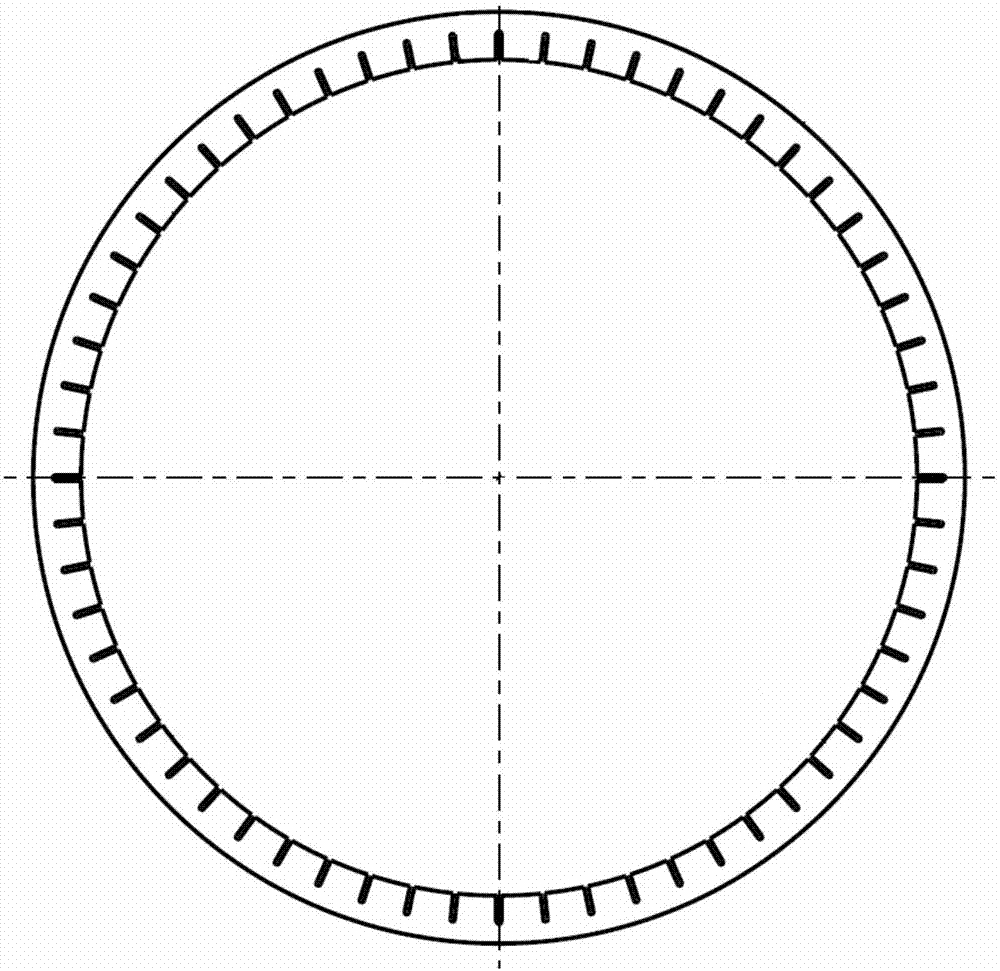

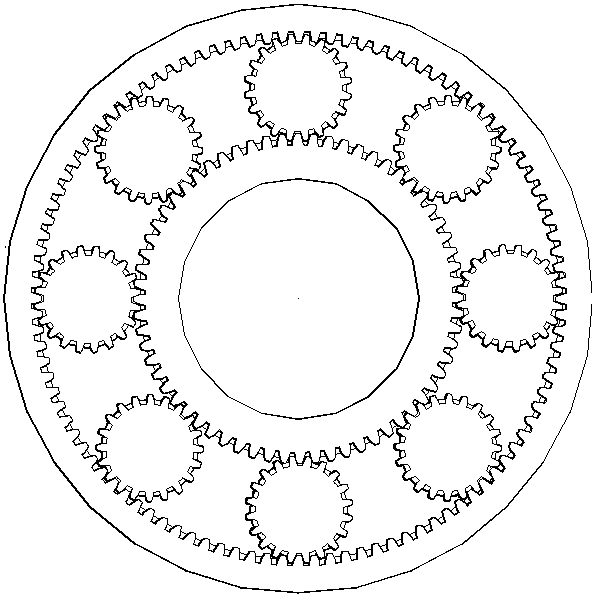

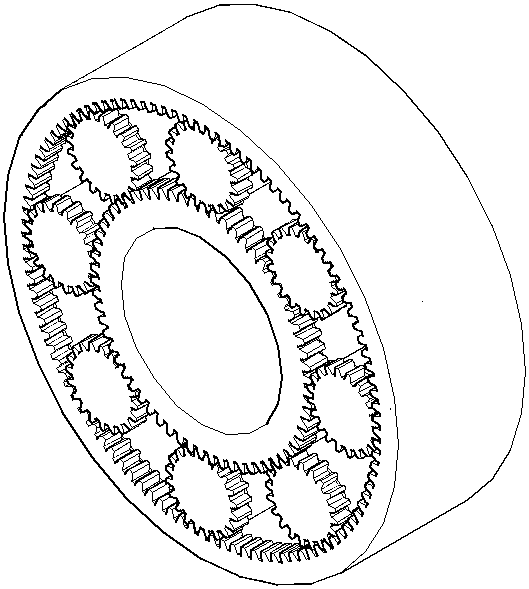

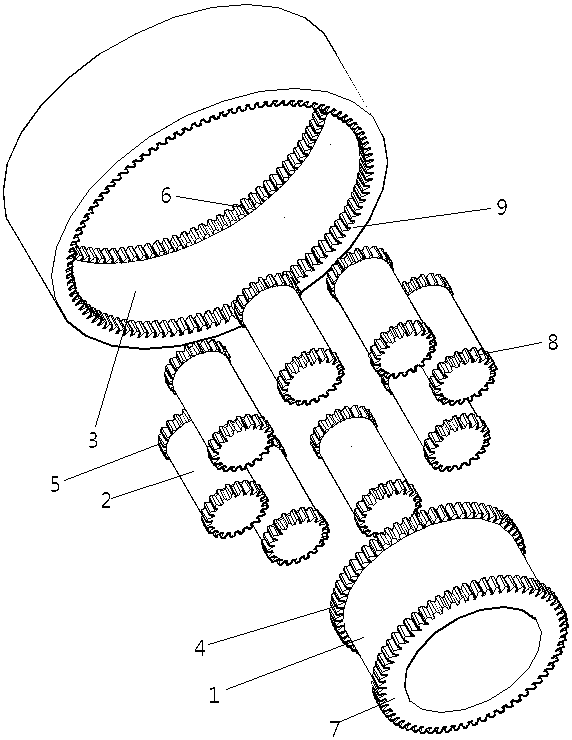

Planetary roller bearing

ActiveCN105805239AIncrease speedImprove efficiencyRolling contact bearingsToothed gearingsRolling-element bearingGear wheel

The invention discloses a planetary roller bearing, relates to the field of mechanical bearings, in particular to a high-speed precise heavy-duty bearing. Two sets of planetary gears are utilized for replacing an ordinary rolling bearing retainer, and the problems that according to the ordinary bearing retainer, due to the fact that the retainer is rubbed and abraded during high-speed running, a rolling body bounces and deviates from the rolling direction, heating of a bearing is intensified, the load is low, and even the bearing is in failure are solved. The planetary roller bearing is the precise heavy-duty bearing high in rotating speed and efficiency, long in service life and high in stability, the lubricating requirement is lower than that of a conventional bearing, and the maintaining cost is low.

Owner:王福成

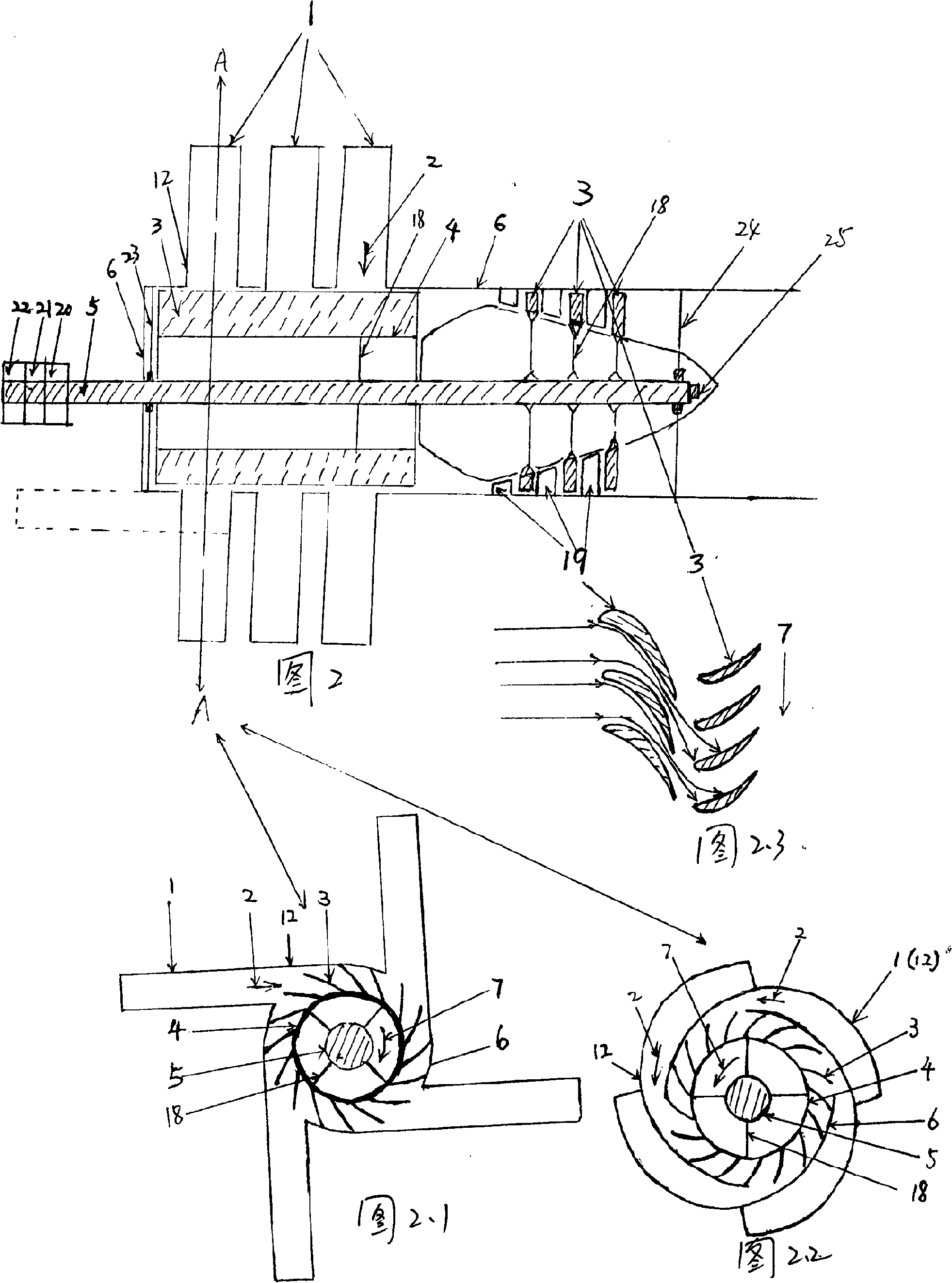

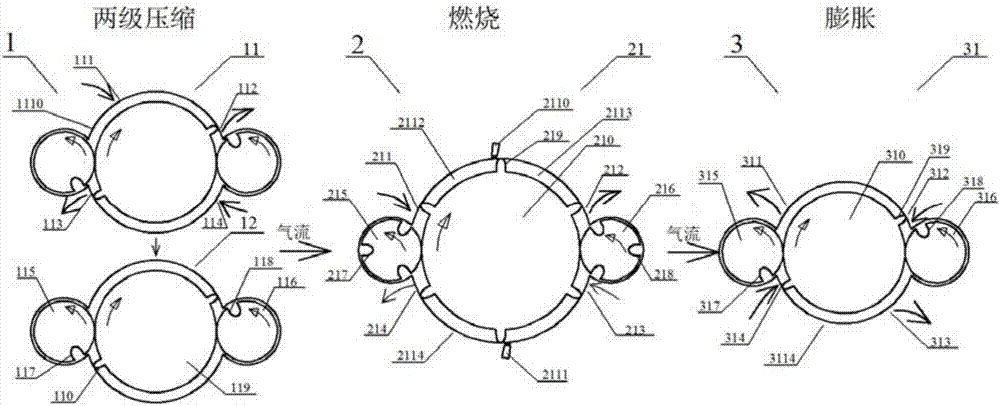

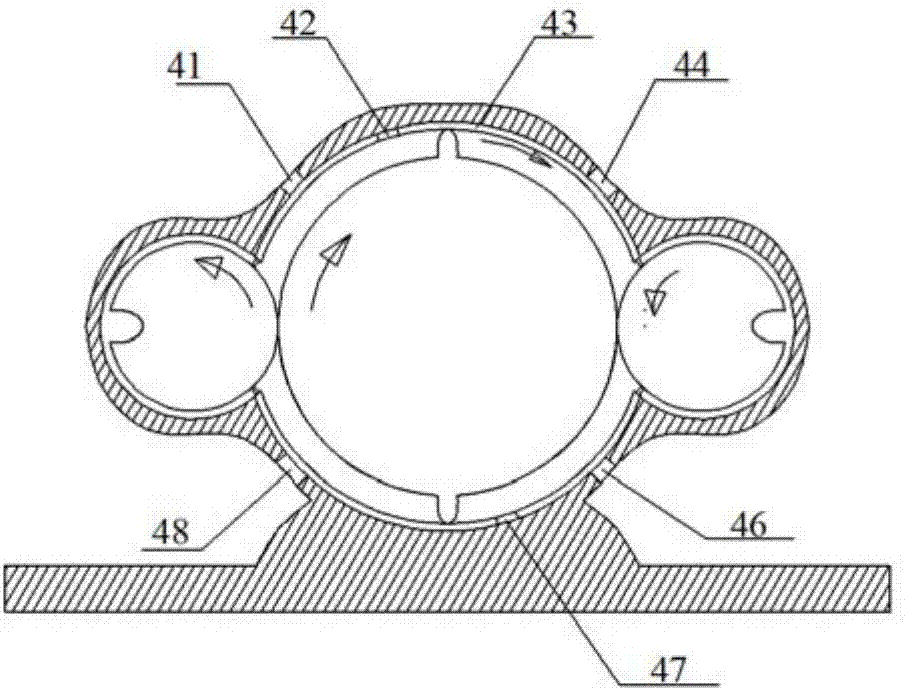

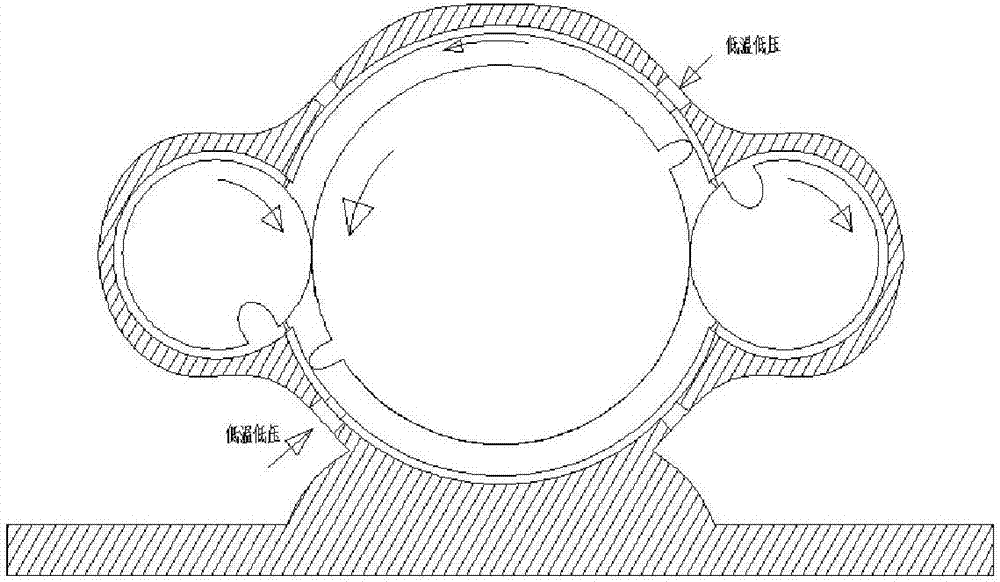

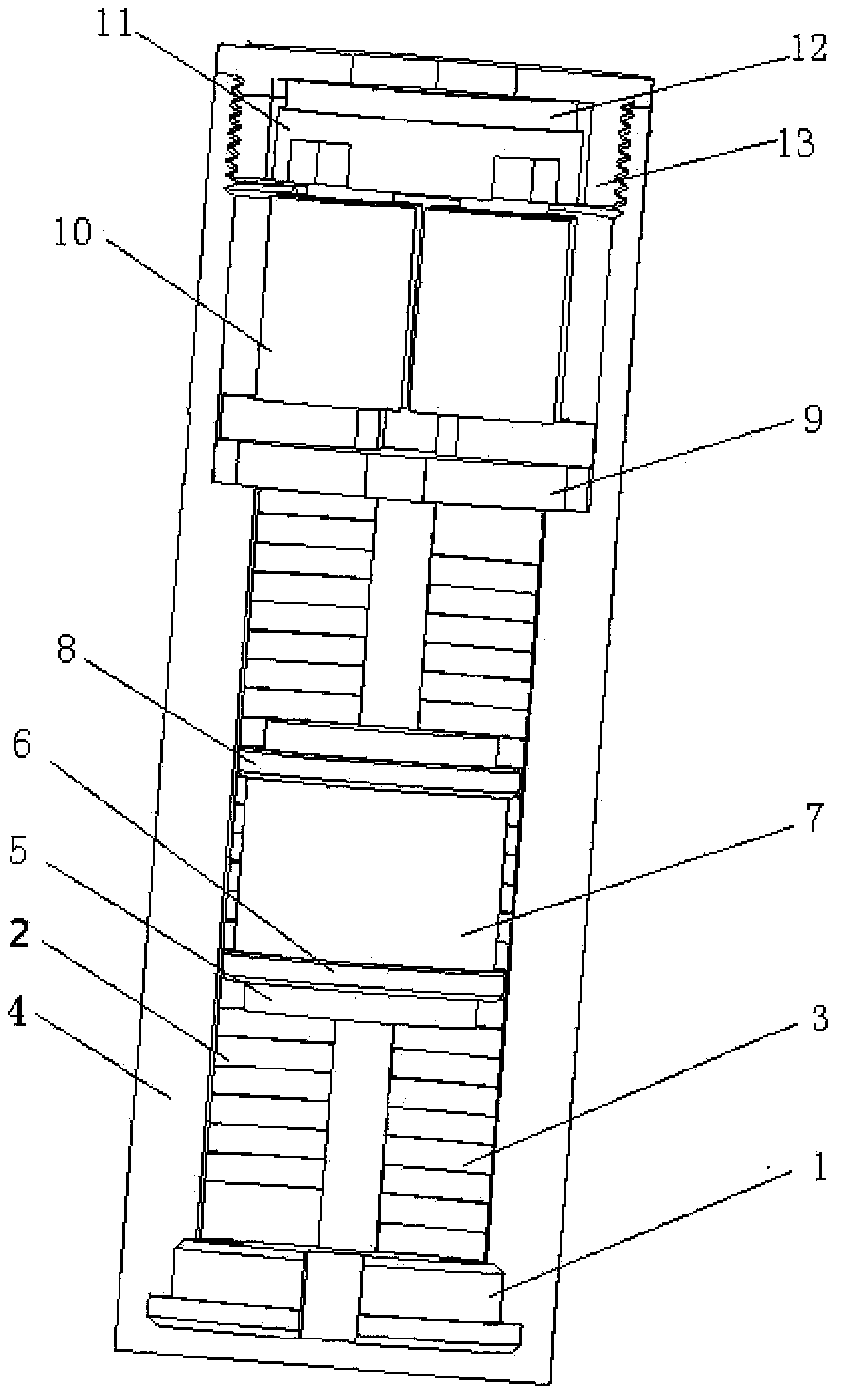

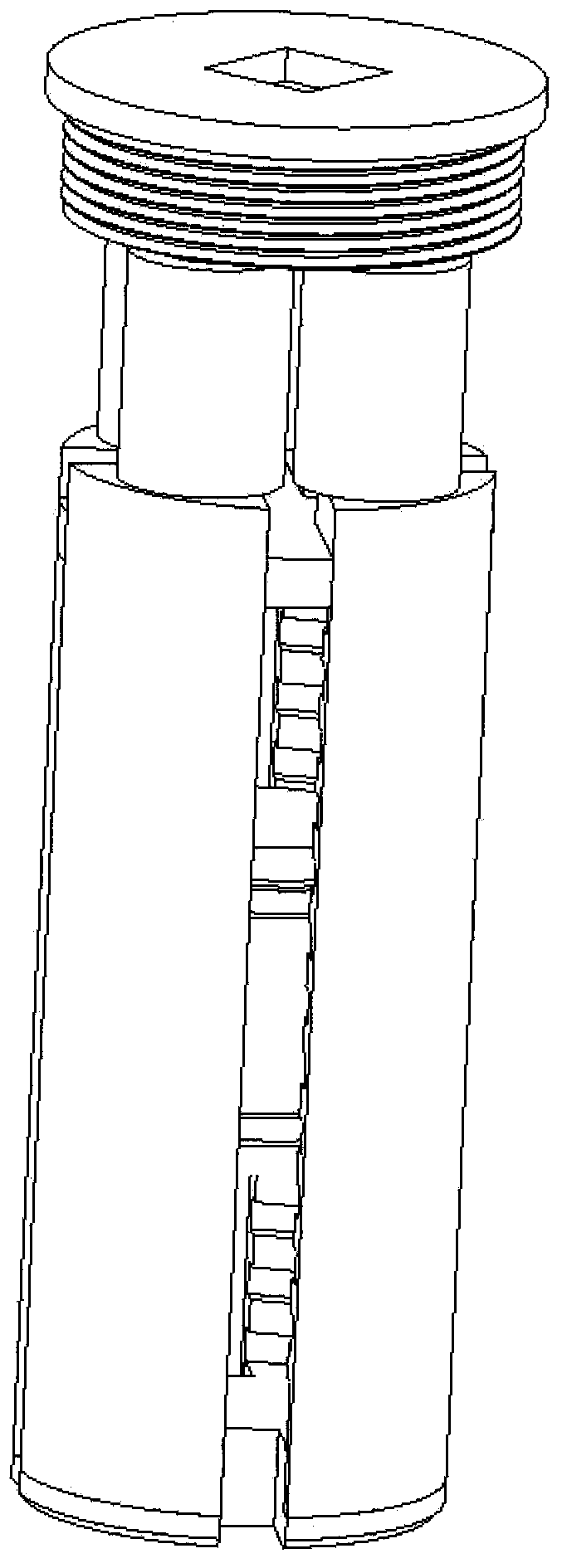

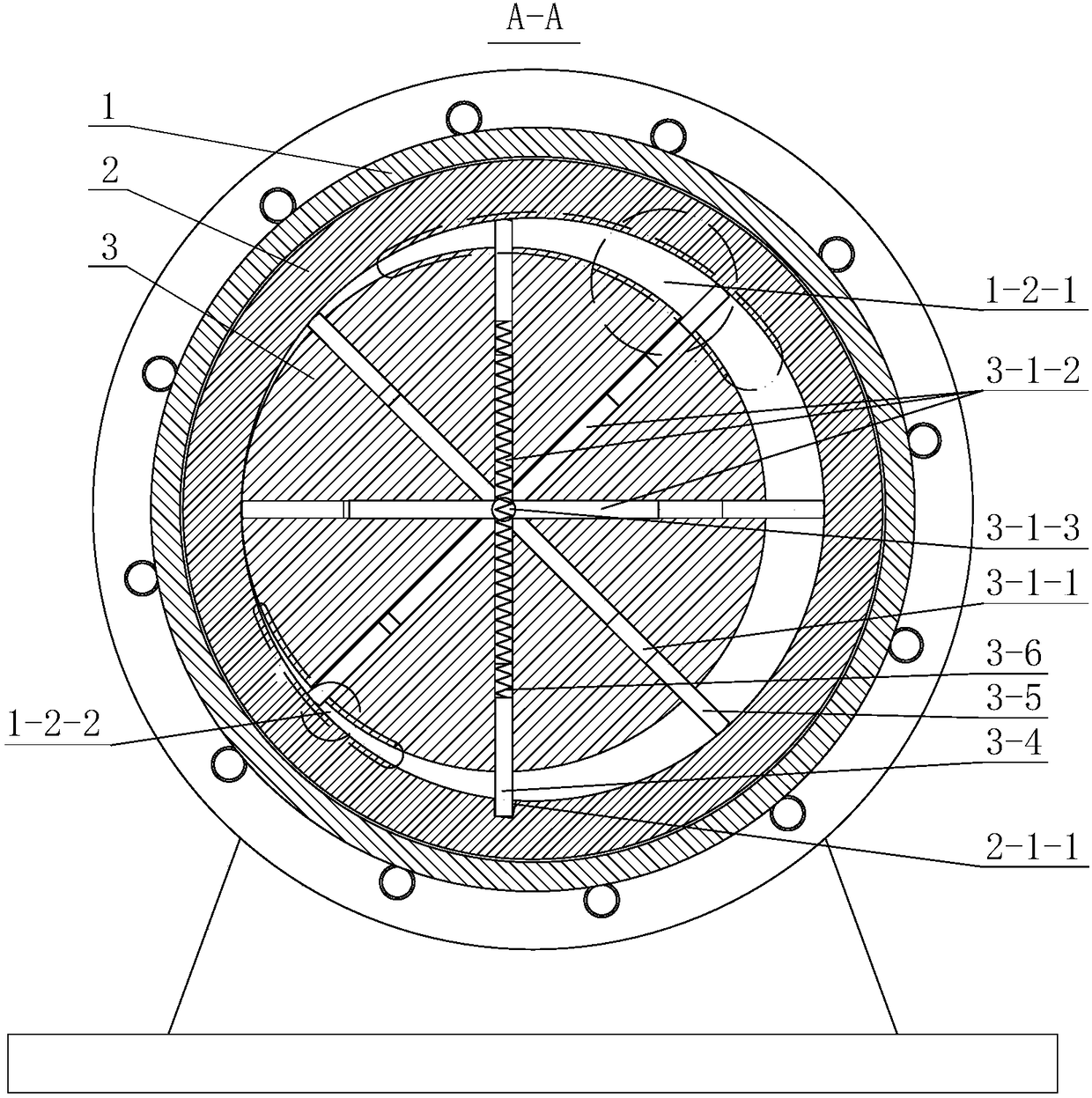

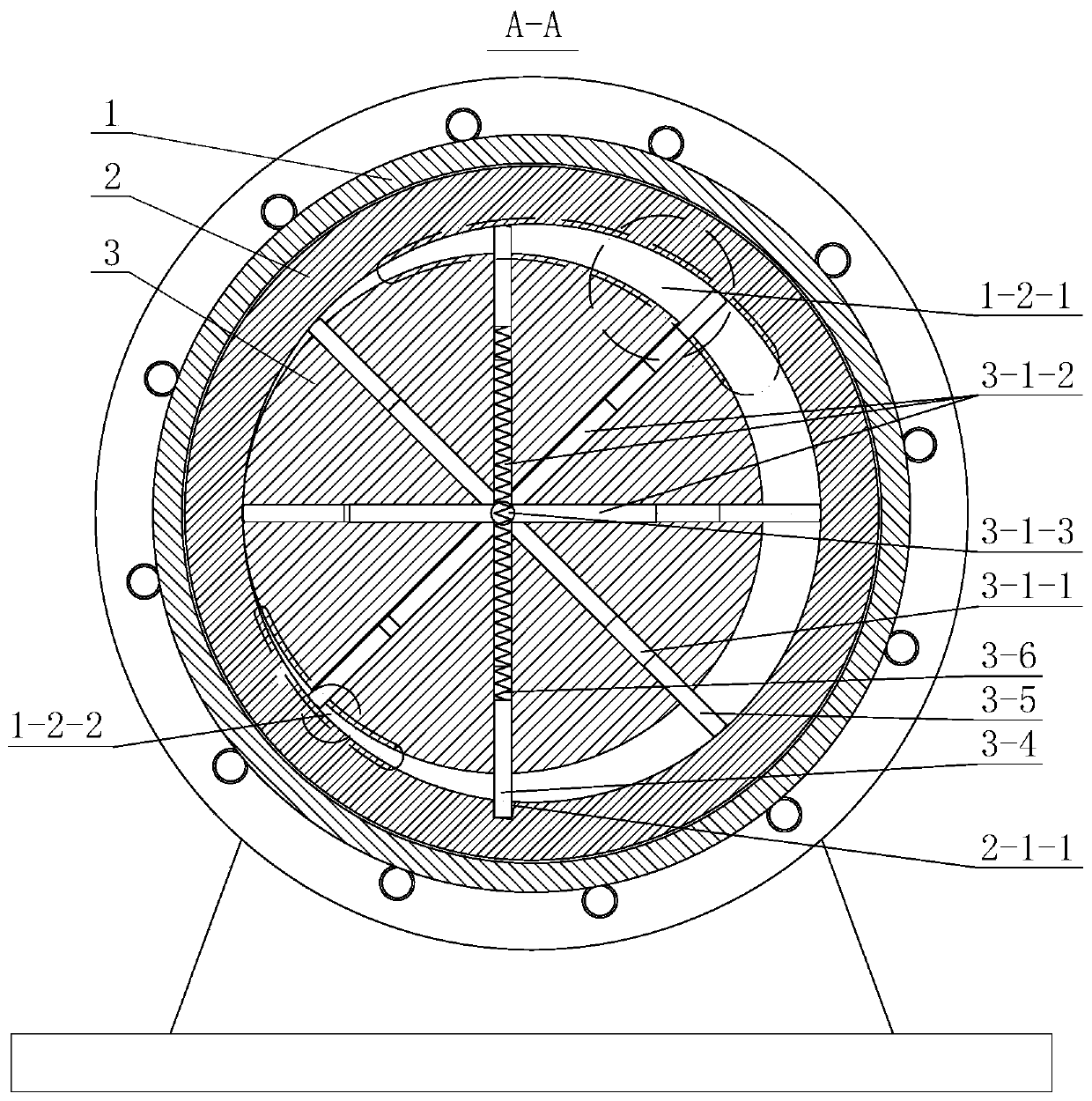

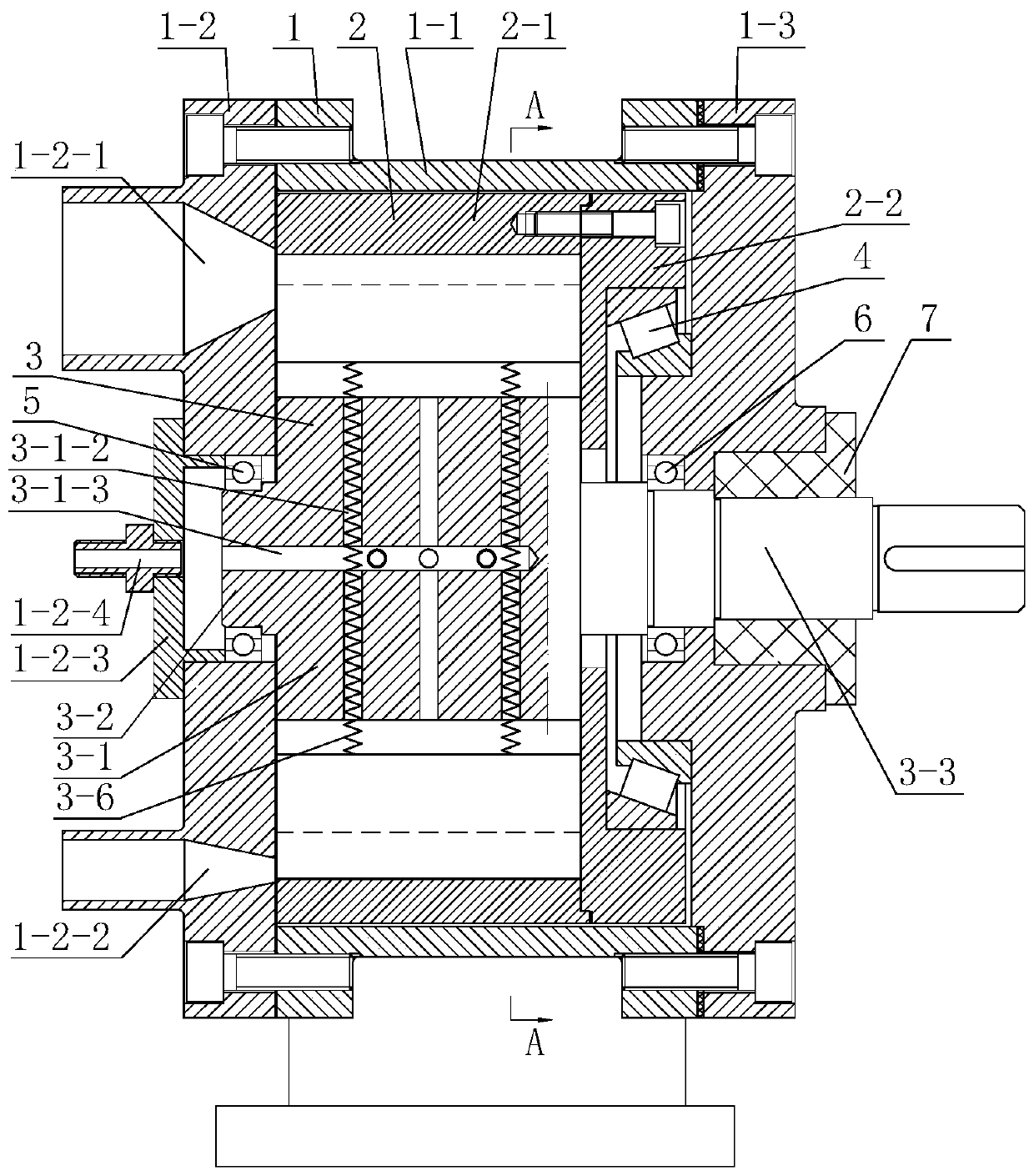

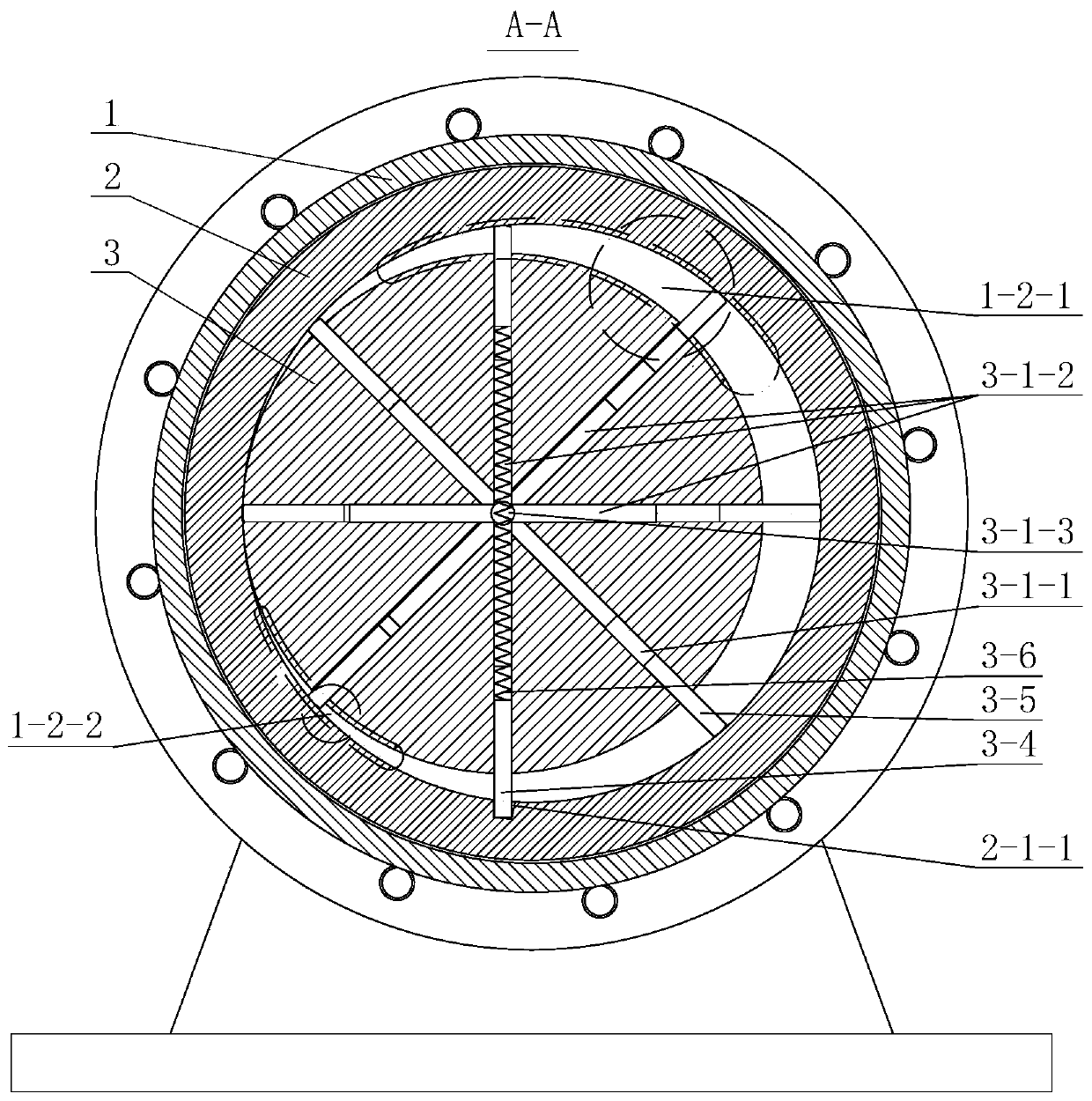

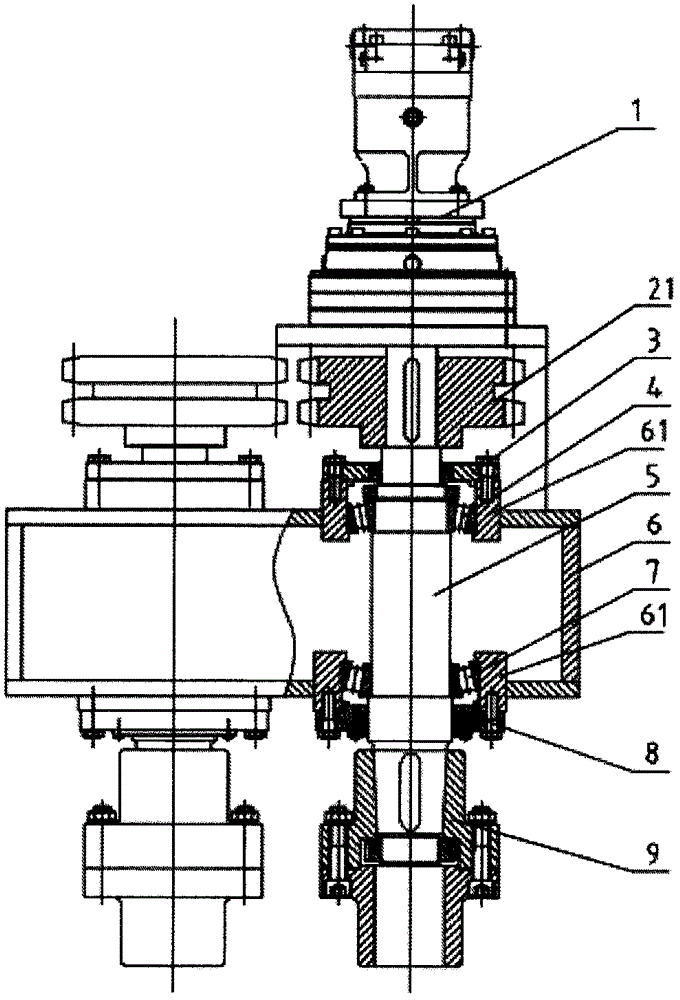

Rotor type engine

ActiveCN106948936ALow lubrication requirementsCycle simpleInternal combustion piston enginesRotary piston pumpsCombustorCore component

The invention provides a rotor type engine and relates to the technical field of engines. The rotor type engine comprises three functional levels including a compression level, a combustion level and an expansion level. The rotor type engine is characterized in that all levels are independent to one another and are connected in series into a whole through a main shaft, and each level is composed of one or more heating power conversion units. The heating power conversion units comprise compressors, combustors and expansion machines at different functional levels. The engine is mainly composed of a main rotor, an auxiliary rotor, a shell and a timing device; main components are all subjected to revolved body machining, the outer diameter of the main rotor is tangent to that of the auxiliary rotor and is two times that of the auxiliary rotor, and the angular speed of the auxiliary rotor is two times that of the main rotor; and the shell contains fixed air feeding openings and exhausting openings, the timing device is a cylindrical piece containing a circumferential air opening, and the timing device and the shell are subjected to sealed treatment through comb teeth. Core components of the compressors, the combustors and the expansion machines are all served as the timing device.

Owner:HUNAN UNIV

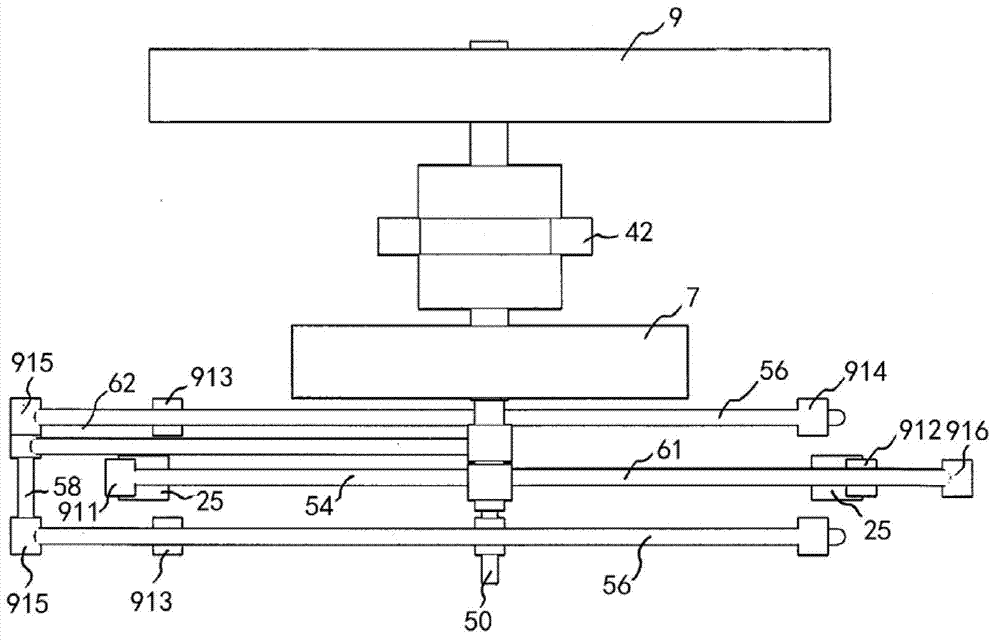

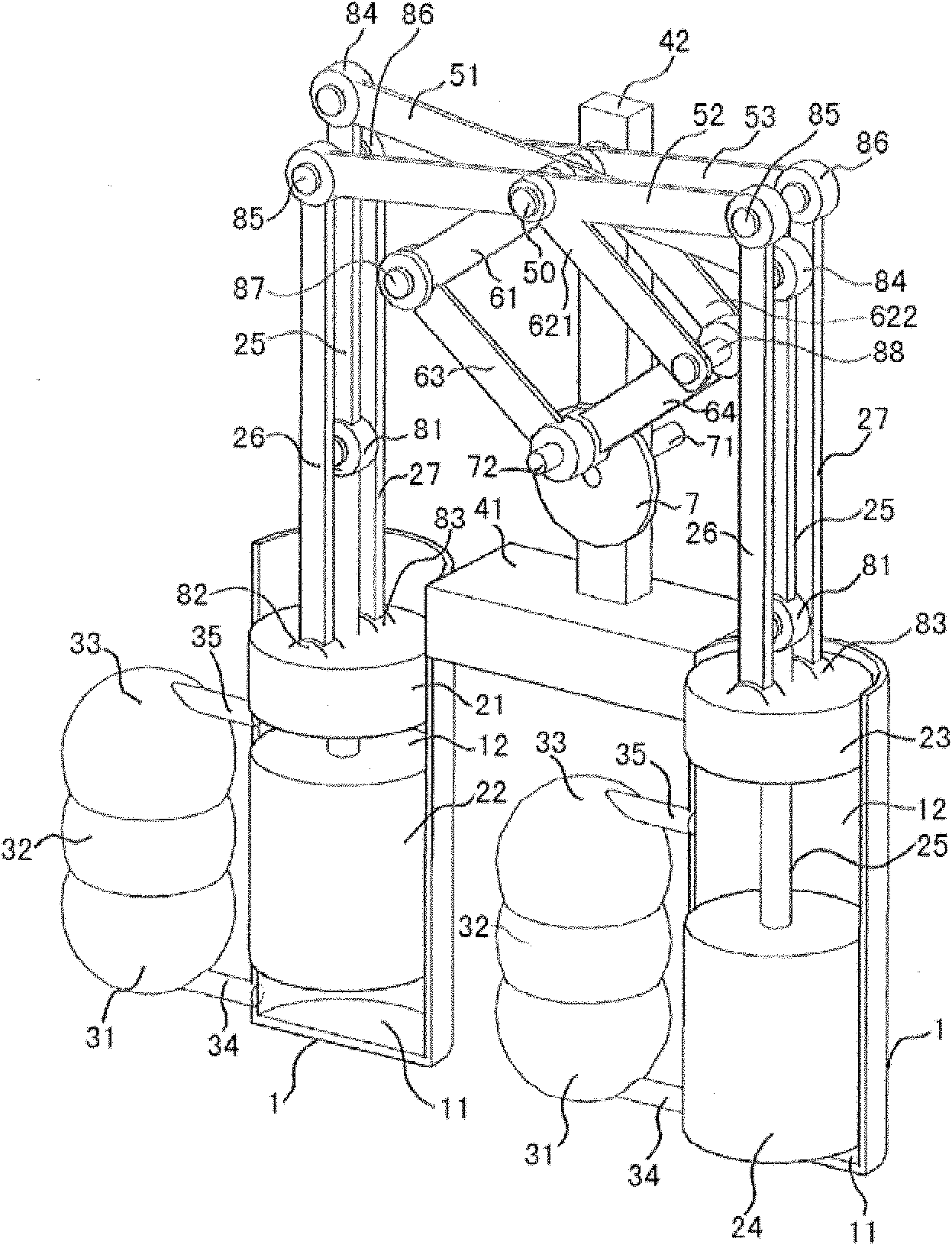

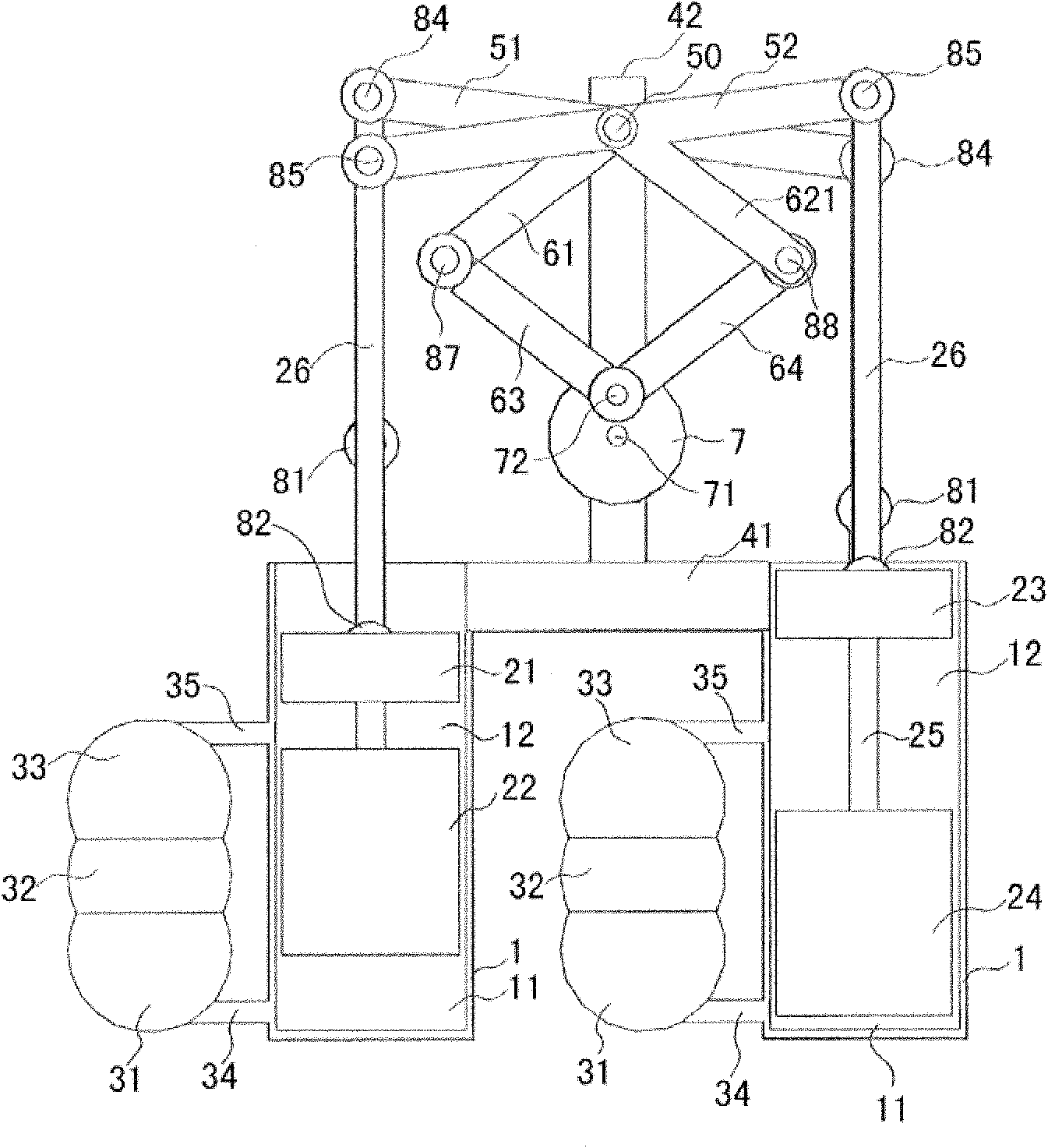

External combustion engine and transmission mechanism thereof

InactiveCN102251877AGuaranteed transmission effectLow costGearingEngine componentsExternal combustion engineEngineering

The invention discloses an external combustion engine and a transmission mechanism thereof. The external combustion engine comprises a hot gas assembly, the transmission mechanism and a crankshaft; the hot gas assembly comprises four groups of heaters, heat regenerators and coolers and four cylinders arranged in a rectangle; disconnected cold and hot cavities are formed in each cylinder; each hot cavity is communicated with a cold cavity gas circuit of a group of heater, heat regenerator and cooler and the other cylinder to form a gas passage; the transmission mechanism comprises a swinging rod group and a connecting rod group; the swinging rod group comprises a first swinging rod and a second swinging rod, the swinging planes of which are mutually parallel; the connecting rod group comprises four connecting rods, namely a first connecting rod and a second connecting rod with equal length, and a third connecting rod and a fourth connecting rod which are extended downwards from a second pivot and a first pivot respectively and have equal length; and the upper ends of the third connecting rod and the fourth connecting rod are hinged with the first connecting rod and the second connecting rod respectively, and the lower ends of the third connecting rod and the fourth connecting rod are hinged with a connecting rod neck of the crankshaft. The external combustion engine has low cost, and is convenient to manufacture.

Owner:杨永顺

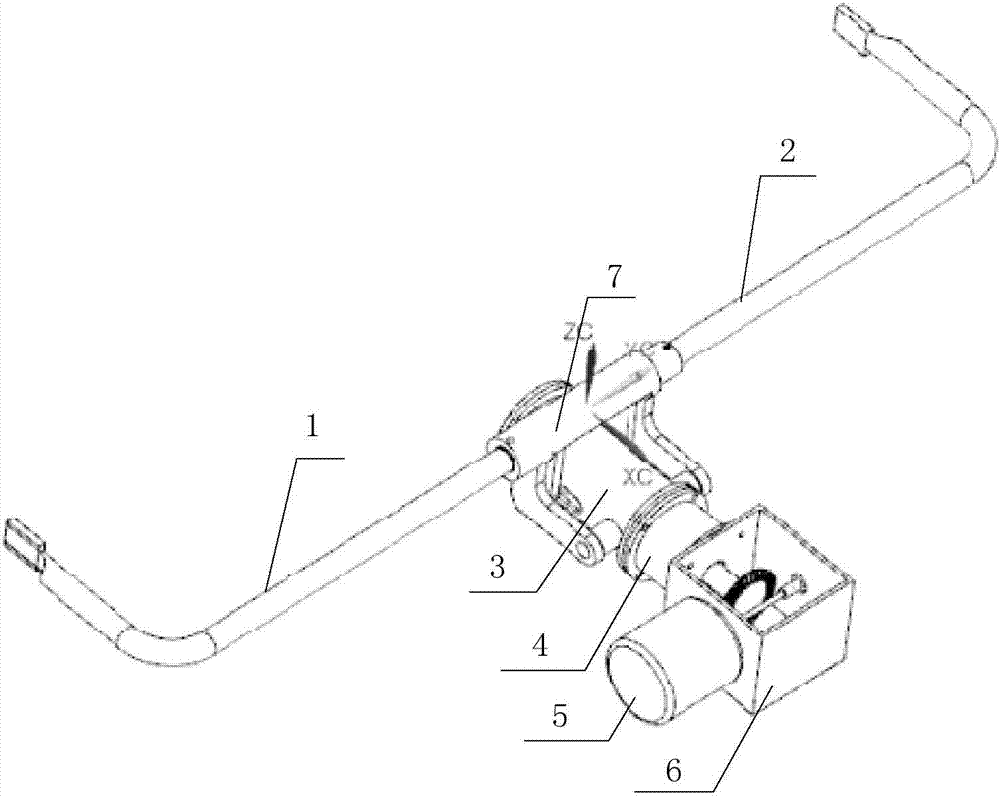

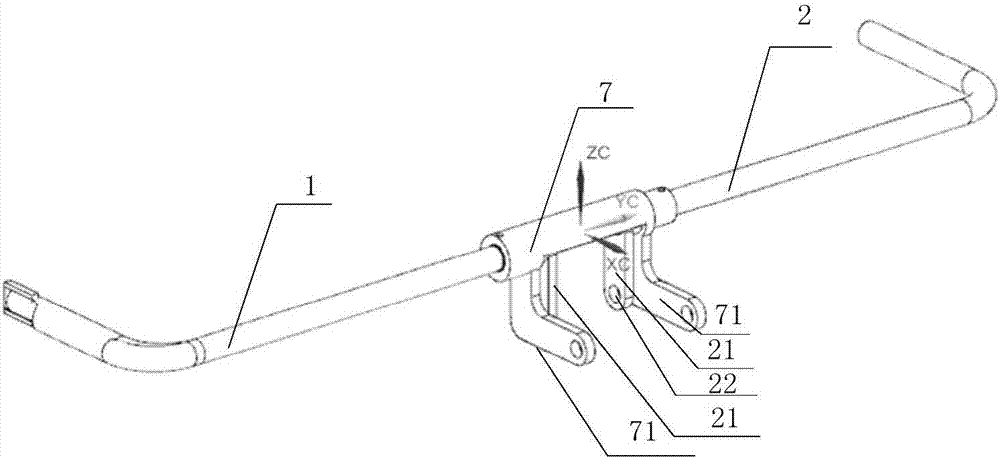

Motor type active transverse stabilizer bar

PendingCN107139673ASimple structureNo complex fitInterconnection systemsResilient suspensionsCouplingElectric machinery

Owner:NANJING UNIV OF SCI & TECH

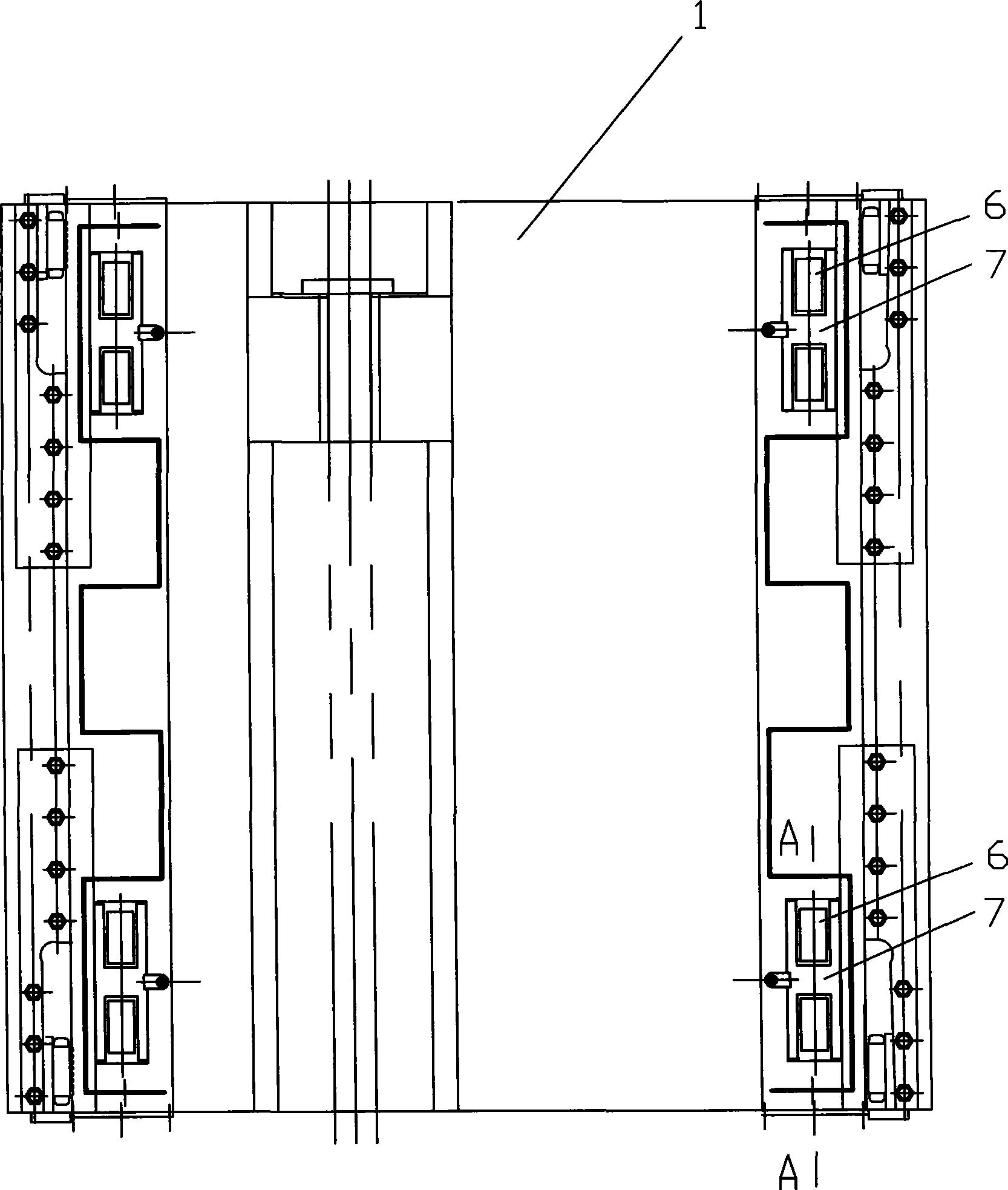

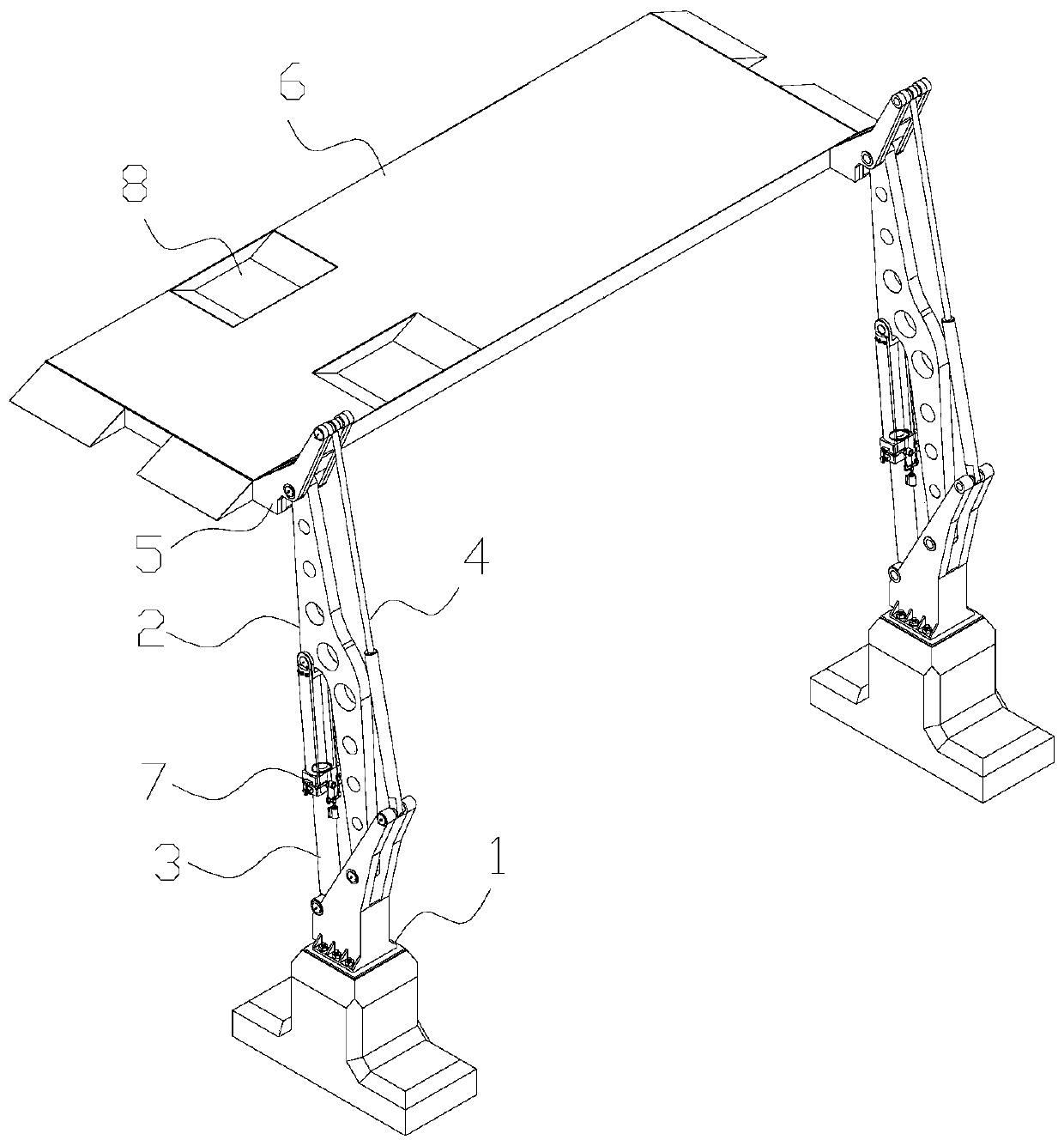

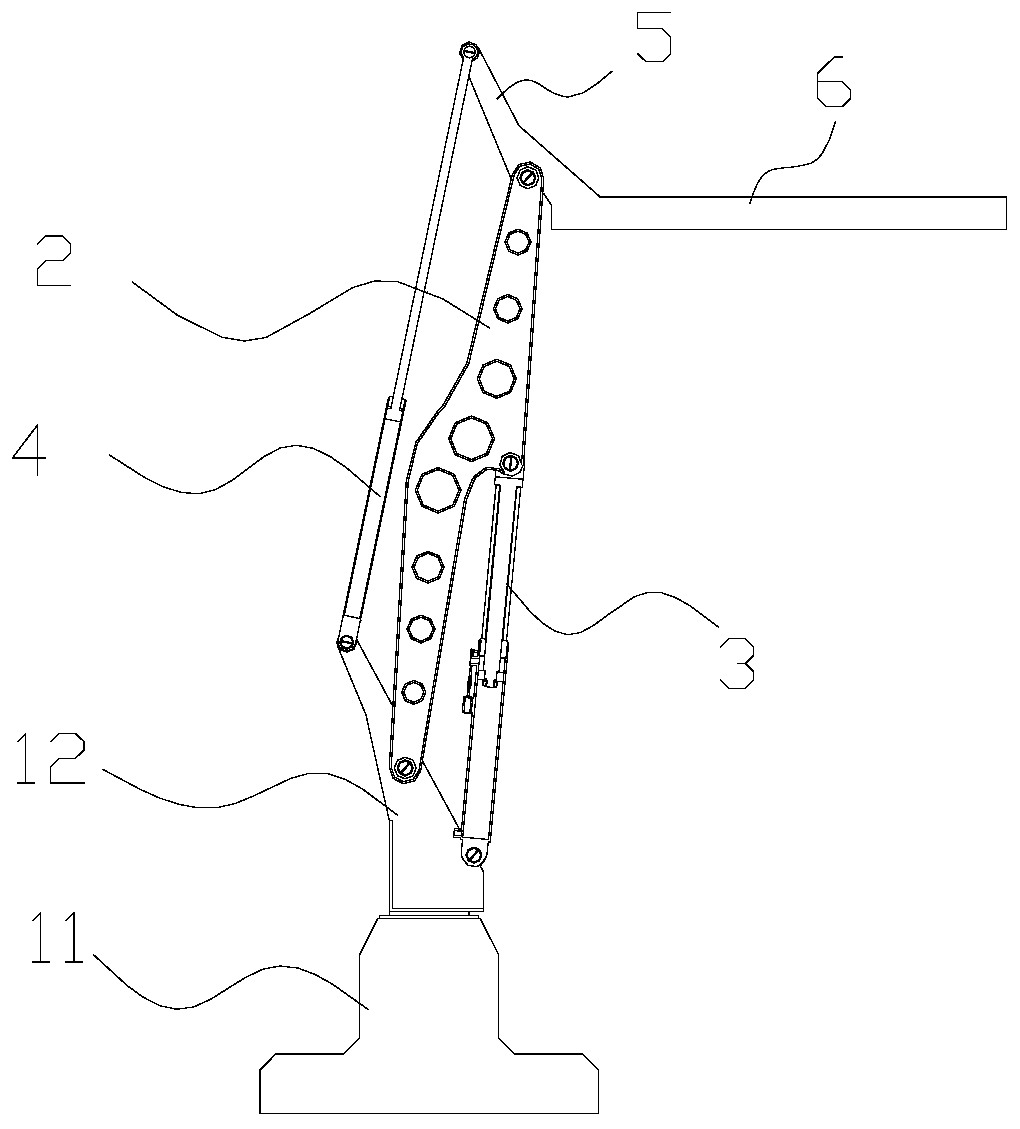

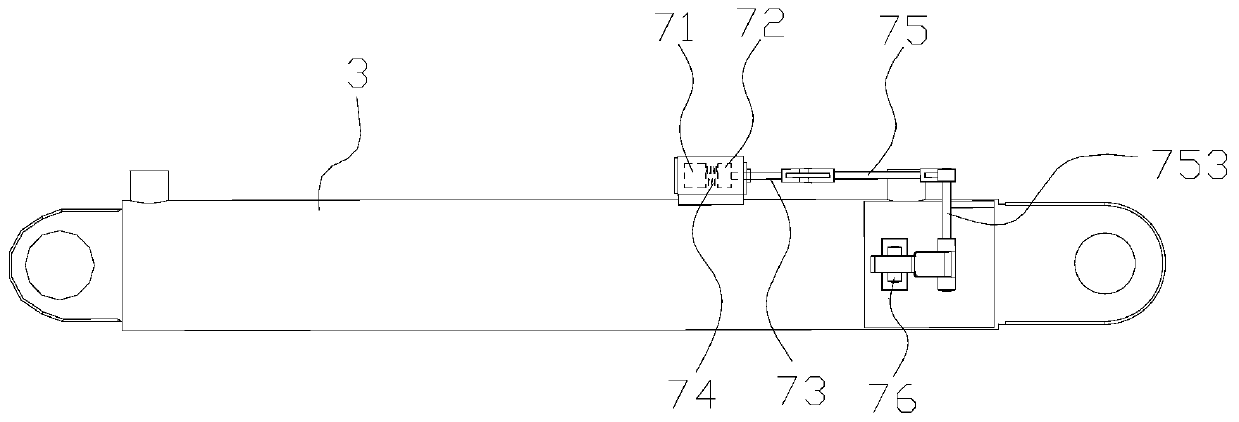

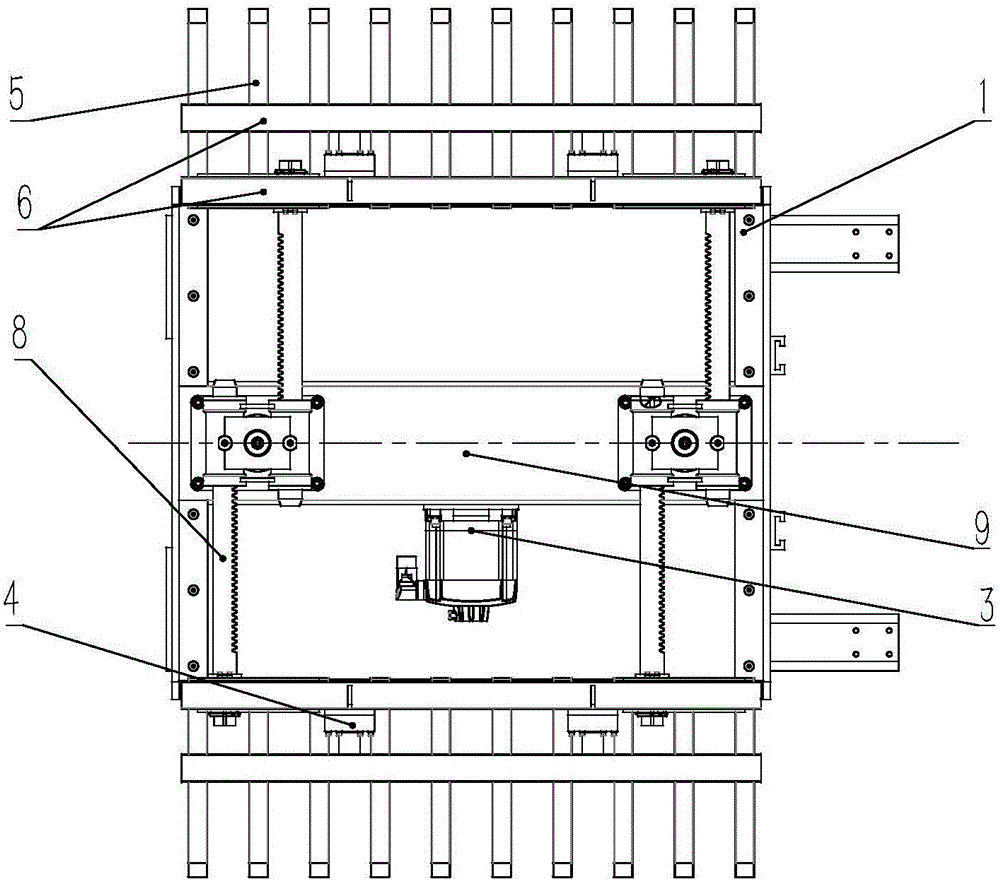

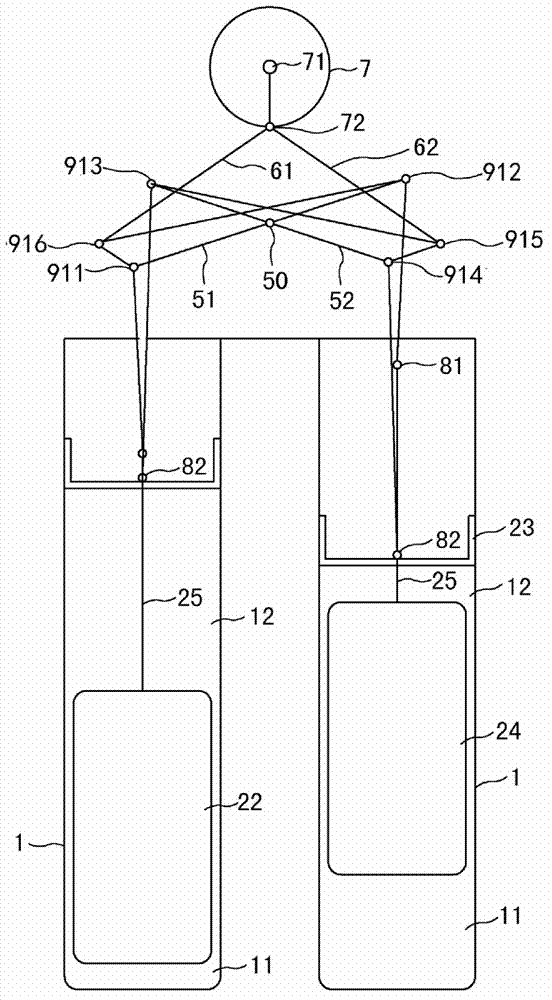

Non-avoidance stereoscopic parking device

The invention relates to a non-avoidance stereoscopic parking device and belongs to the technical field of stereoscopic parking devices. The non-avoidance stereoscopic parking device comprises bases,large arms, lifting hydraulic cylinders, connecting pieces, platform arms and a parking platform, wherein the large arms, the lifting hydraulic cylinders and the connecting pieces are all arranged onthe bases; the connecting pieces are arranged on the upper sides of the large arms; the lifting hydraulic cylinders are arranged on the lower sides of the large arms; one ends of the large arms are hinged to the bases and the other ends of the large arms are hinged to the lower ends of the platform arms; one ends of the connecting pieces are hinged to one ends of the bases, and the other ends of the connecting pieces are hinged to the upper ends of the platform arms; the large arms, the bases, the connecting pieces and the platform arms form parallelogram mechanisms by being arranged around; one ends of the lifting hydraulic cylinders are hinged to the bases, and the other ends of the lifting hydraulic cylinders are hinged to the large arms; the lifting hydraulic cylinders are equipped with lifting self-locking mechanisms; and the parking platform is fixedly connected with the platform arms. The stereoscopic parking device of the invention has the advantages of simple structure, smallsize, low cost and wide application range.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

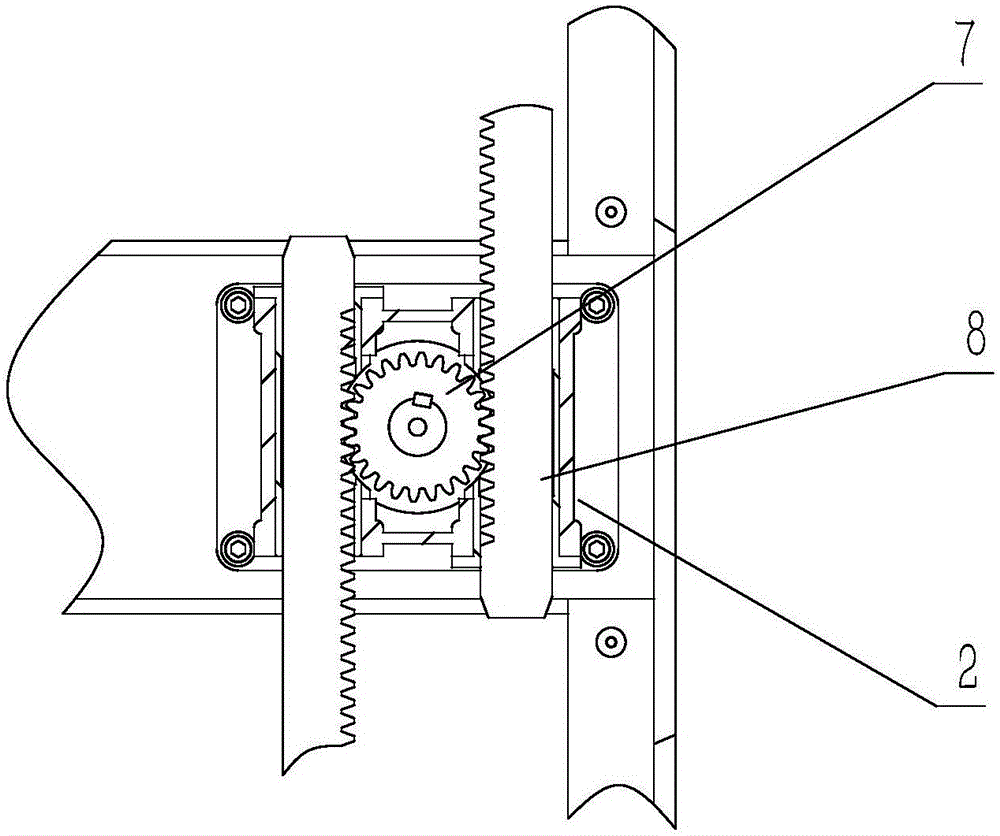

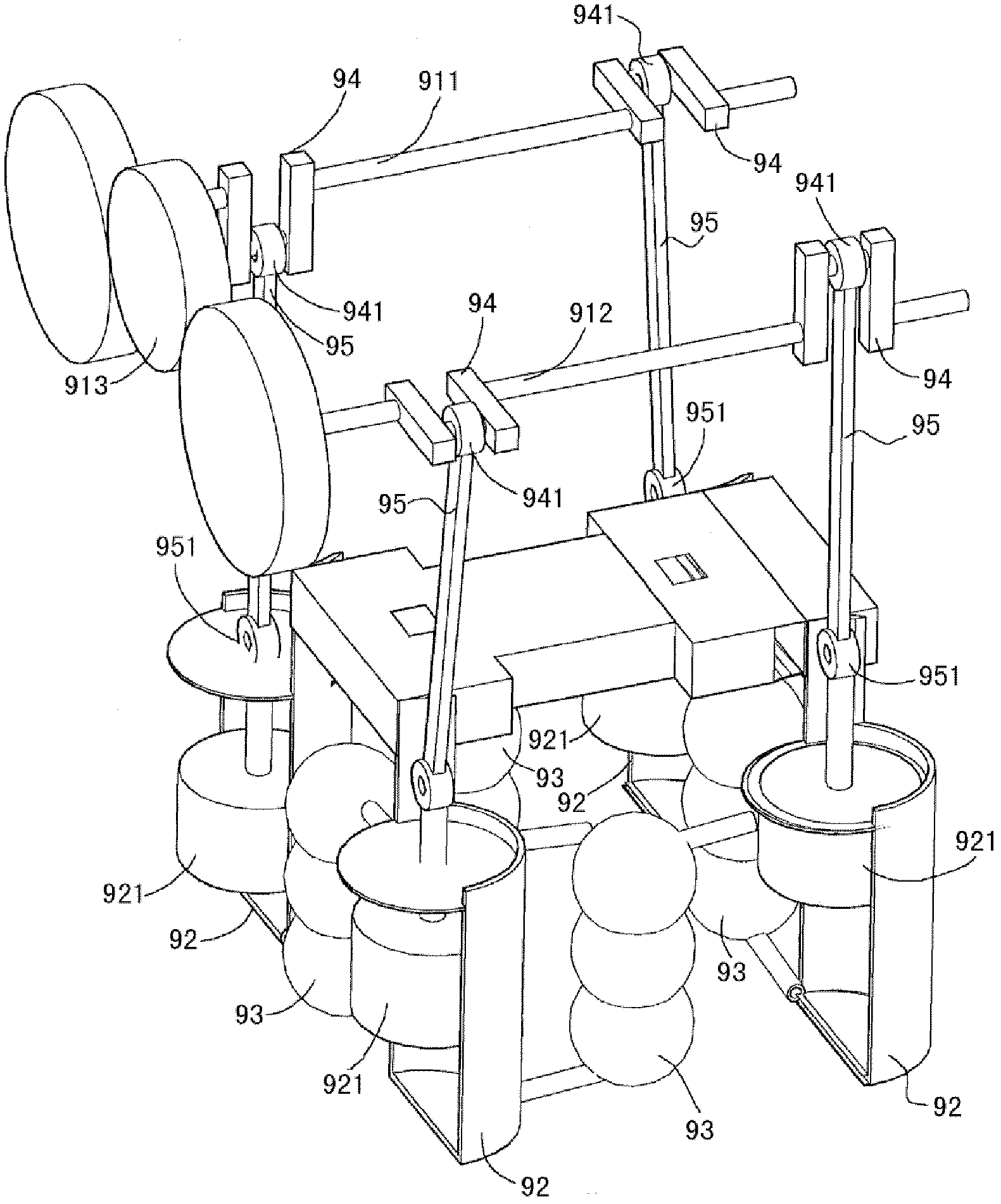

Combing mechanism for full-automatic underground parking lot and use method

The invention relates to a combing mechanism for a full-automatic underground parking lot and a use method. The combing mechanism comprises a box, a servo motor, a speed reducer, gears, racks, an entire vehicle component and a guide base, wherein the output end of the servo motor is used for driving the gears to be connected through the speed reducer; both sides of the gears are meshed with two racks; the end parts of the racks are fixedly connected with the entire vehicle component; the gears are used for driving the racks to translate in the guide base. The combing mechanism has the advantages that the combining mechanism is fixed to a trolley conveying mechanism, and plays roles in carrying rear wheels of a vehicle and correcting a vehicle position. The overall structure is simple and compact, the lubricating requirement is low, the fault rate is lowered, stable performance of underground parking lot equipment is ensured, and the requirement of underground damp environment can be met. Automatic parking is realized, and the parking efficiency is increased. A non-standard reducing mechanism is adopted to fulfill the aim of driving two gears with one servo motor. The entire vehicle component is of a steel structure form, so that the vehicle position can be corrected, and force needed for correcting the vehicle is displayed.

Owner:ANSHAN ZIZHU ENG EQUIP MFG

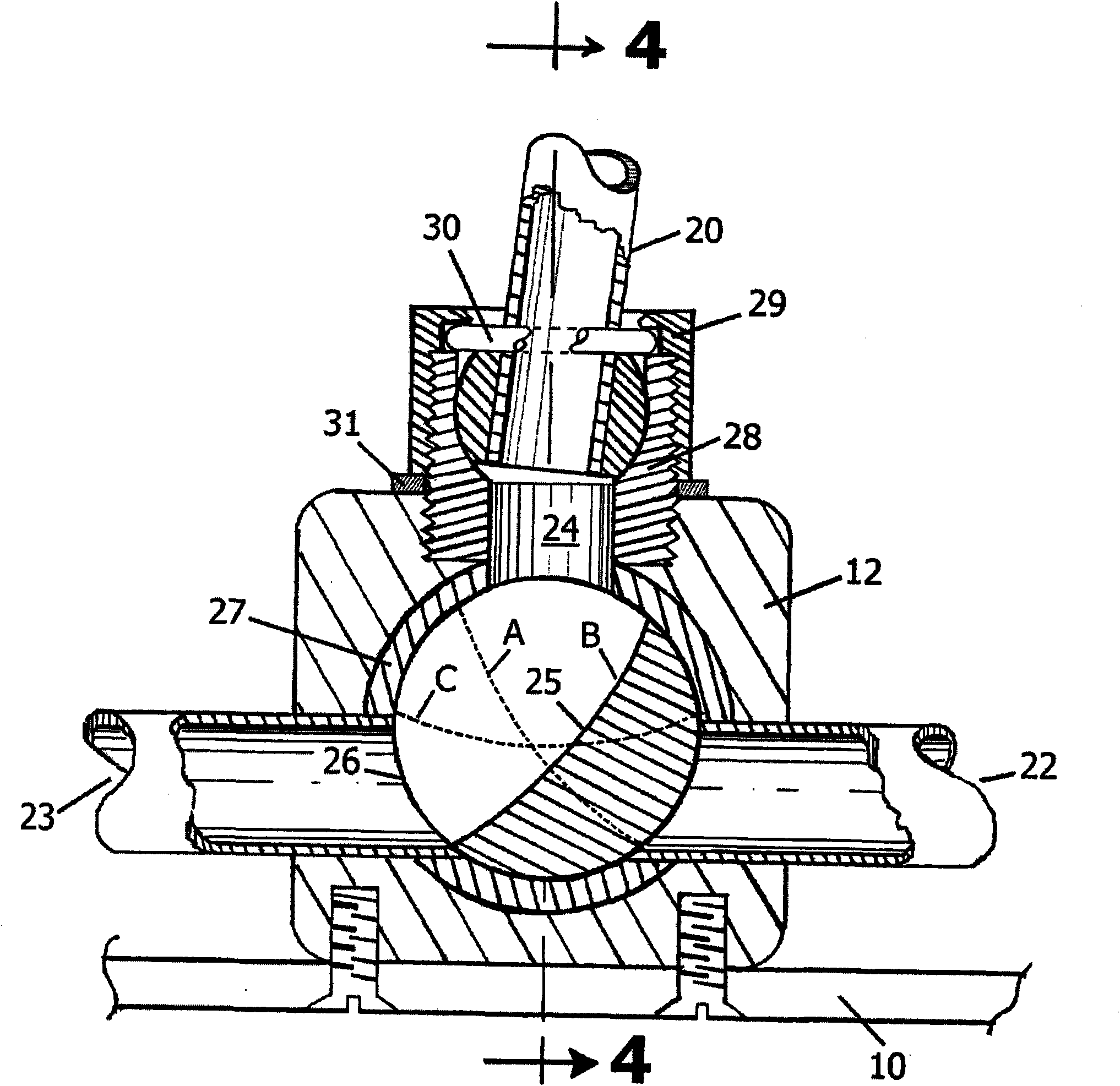

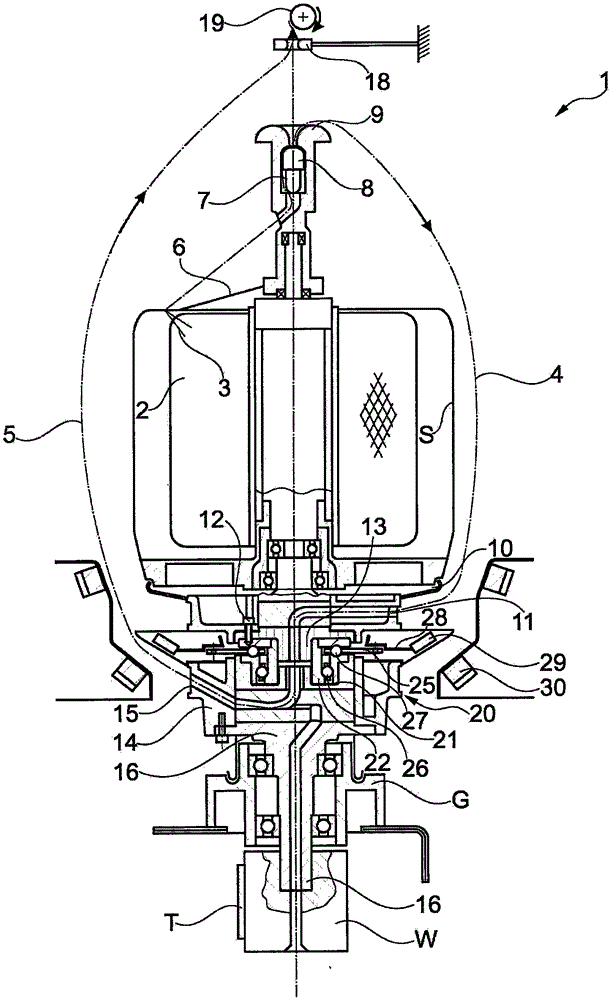

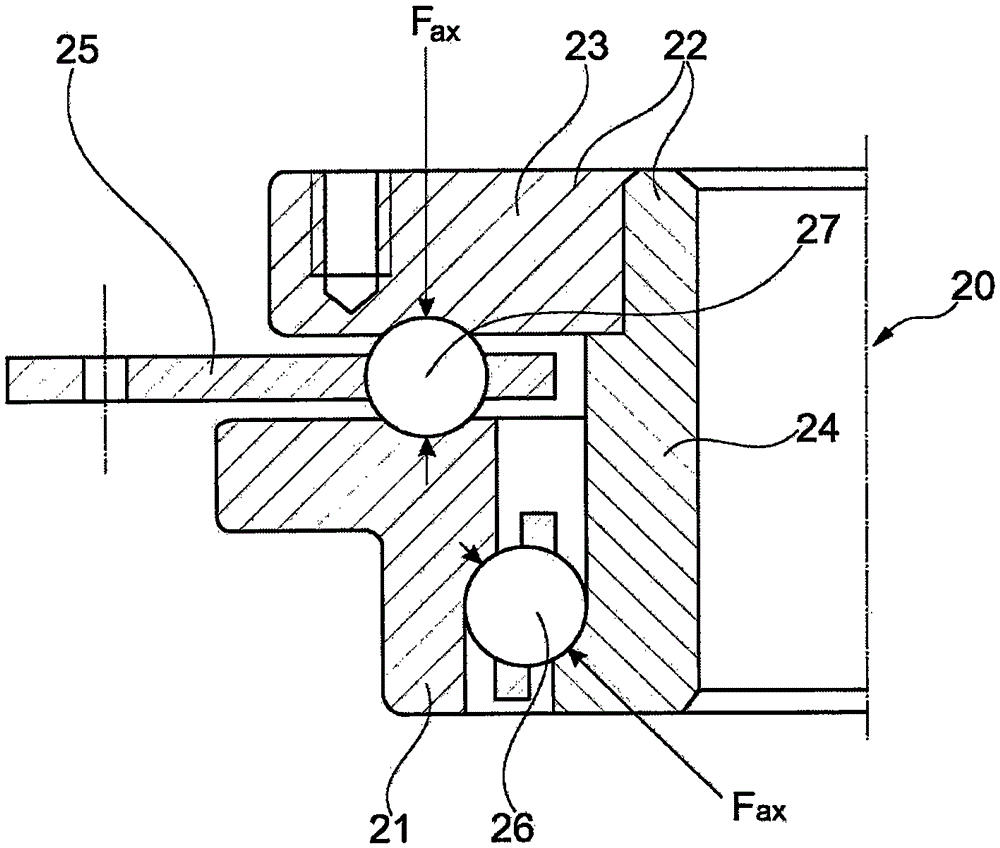

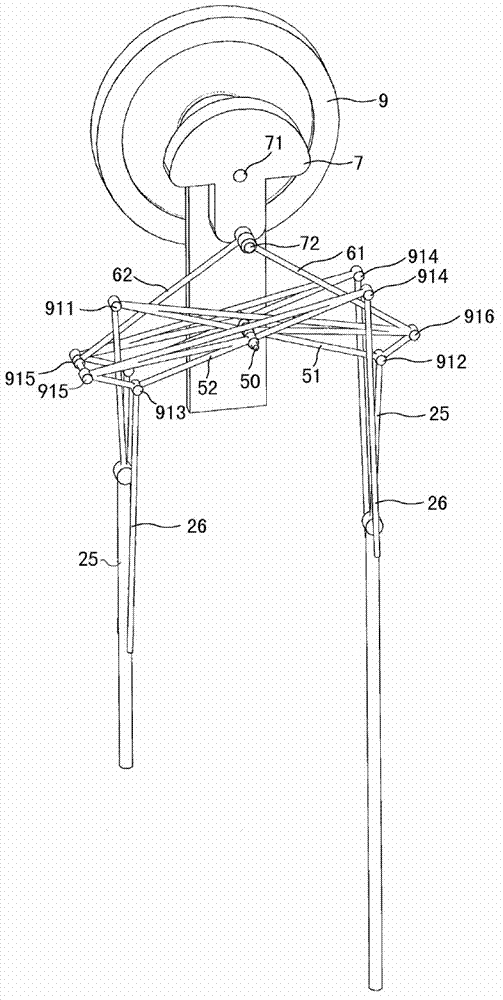

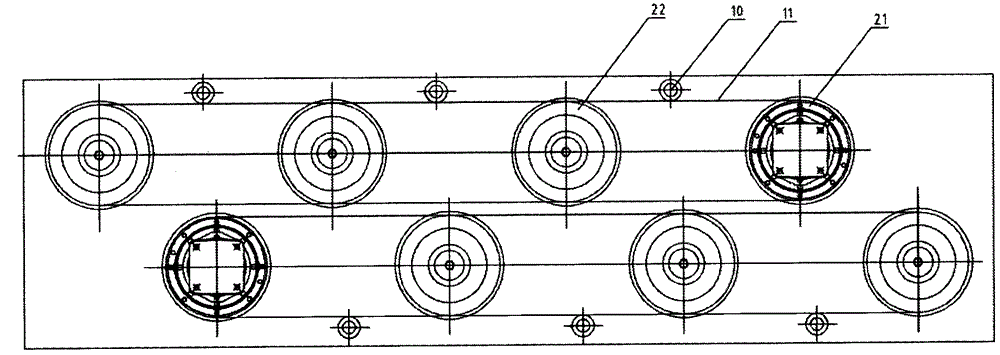

Multi-thread yarn spindle for yarn twisting machine

InactiveCN105671706AEnsure force actionEqual tensionRolling contact bearingsTextile treatmentYarnThrust bearing

The invention relates to a multi-thread twisting spindle (1) for yarn twisting machines. The multi-thread twisting spindle includes an upper rotor (10) and a lower rotor (14), which rotate concentrically in opposite directions, wherein one of the rotors (10, 14) is driven and transmits the movement to the other rotor (10, 14) by means of a transmission device (20). According to the invention, the movement between the driven rotor (10, 14) and a transmission device output rotor (10, 14) is transmitted via at least one thrust bearing (27) and at least one radial bearing (26), wherein a cage (25) arranged in the thrust bearing (27) is present which is secured against rotation.

Owner:SAURER GERMANY GMBH & CO KG

Electromagnetic vibration power generation device

An electromagnetic vibration power generation device comprises a casing, wherein a vibrator capable of vertically sliding is arranged in the casing. The vibration power generation device further comprises four induction coils, a front magnet yoke, a back magnet yoke, a left magnet yoke, a right magnet yoke, an upper magnet yoke support and a lower magnet yoke support. The casing is a cylinder with a bottom and is made of non-magnetic materials, four guide rails are evenly distributed on the inner lateral wall of the cylinder, the vibrator can be slidingly arranged on the guide rails, and the smallest dimension of each guide rail in the radial direction is smaller than the radius of the top of each protruded square tooth on each magnet yoke. The lower magnet yoke support, the magnet yokes, the vibrator, the upper magnet yoke support, the induction coils and yoke tops are arranged in the casing from bottom to top in sequence. The four magnet yokes are made of soft magnetic materials and symmetrically distributed in an adjacent mode along the circumferential direction of a cavity of the casing, the two magnet yokes at opposite positions are completely identical, and the square teeth of the adjacent magnet yokes are distributed in a convex-concave stagger mode. The electromagnetic vibration power generation device is small in vibration resistance, high in magnetic circuit utilization rate and high in power generation efficiency.

Owner:SHANDONG SHENGRUN AUTOMOBILE

Sliding piece type compressor with cylinder rotating with rotor

ActiveCN108194357AReduce friction lossImprove efficiencyRotary piston pumpsRotary piston liquid enginesPneumatic cylinderFriction loss

The invention discloses a sliding piece type compressor with a cylinder rotating with a rotor. The sliding piece type compressor with the cylinder rotating with the rotor includes a cylindrical machine shell, wherein a pneumatic cylinder is arranged in the cylindrical machine shell and is coaxial with the cylindrical machine shell. The rotor is arranged in the pneumatic cylinder and is arranged eccentrically with the pneumatic cylinder, and an air inlet and an air outlet are formed in the left end surface of the machine shell. The air inlet and the air outlet are correspondingly located in a position changed from being small to being big and a position change from being big to being small along the direction of the rotor rotation, the positions are located in crescent shaped clearance areas between the pneumatic cylinder and the rotor. More than eight even numbered axial rectangular grooves are evenly formed in the rotor, and at least two radial through holes are formed in the rectangular grooves. A sliding piece is embedded in the rectangular grooves, and one wide sliding piece is embedded in the inner wall of the pneumatic cylinder. The rest of the sliding pieces abut against theinner wall of the pneumatic cylinder under the action of a compression spring. The compressor has the advantages of small friction loss and high efficiency because the pneumatic cylinder rotates along the compressor.

Owner:SOUTHEAST UNIV

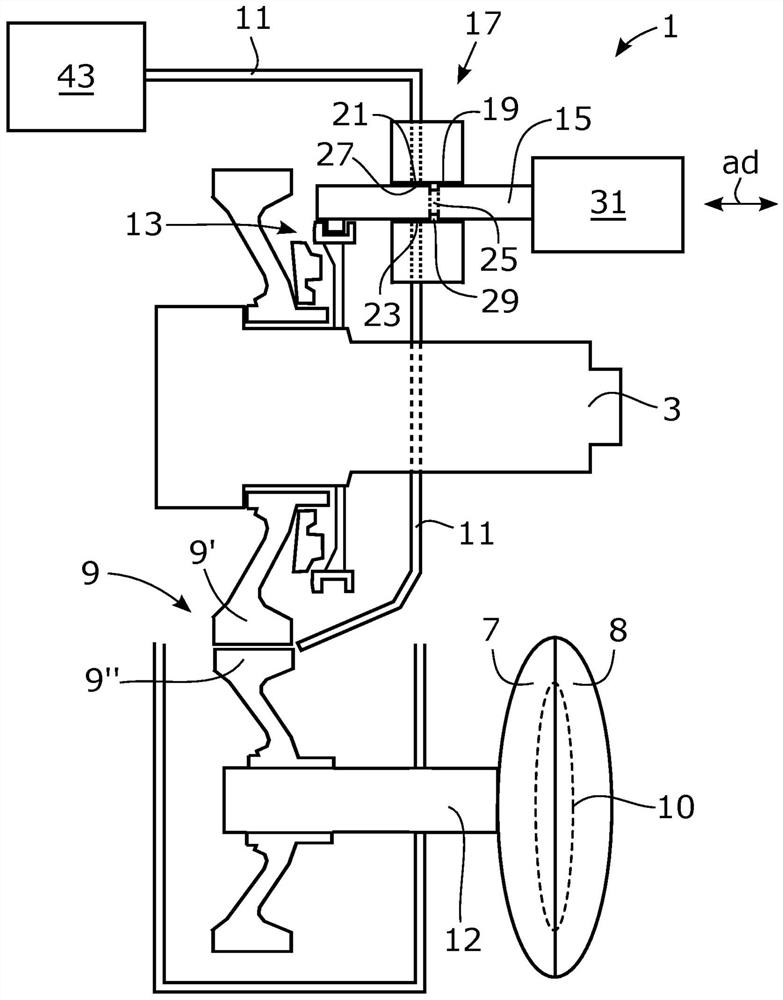

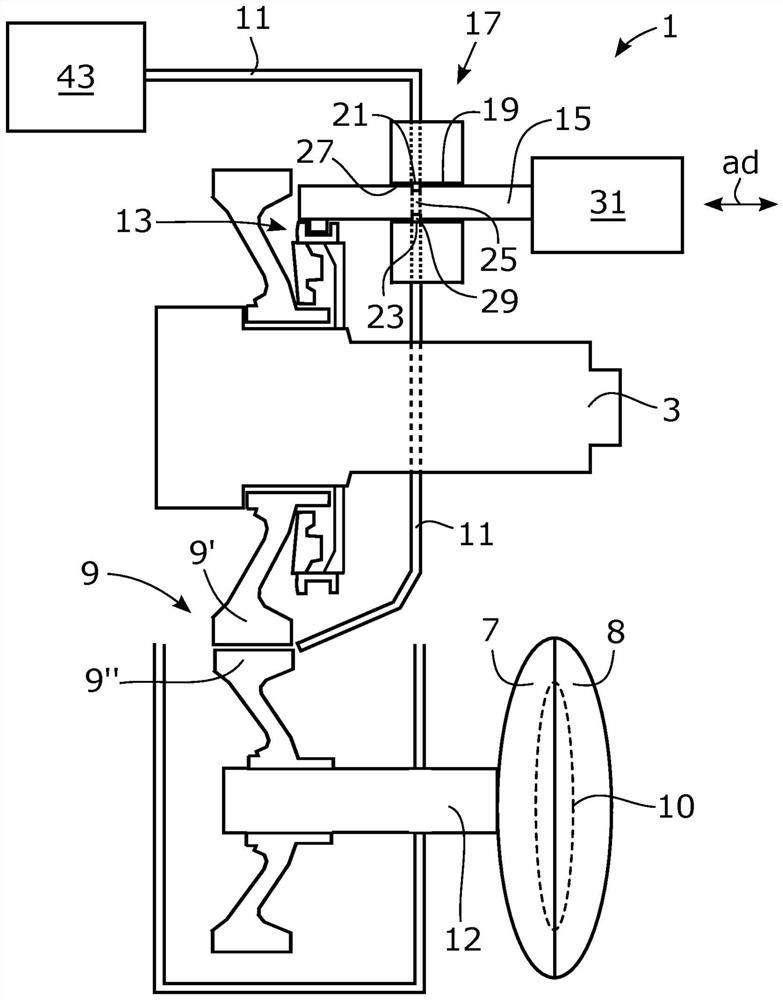

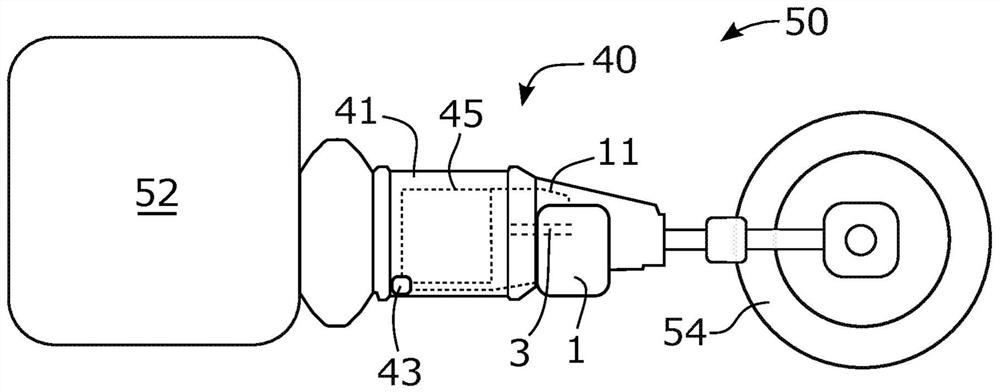

Retarder arrangement and related devices

PendingCN112673197ALow parasitic lossOptimize layoutBraking element arrangementsLiquid resistance brakesActuatorControl theory

A retarder arrangement (1) is disclosed configured to brake rotation of a shaft (3) of a vehicle (5). The retarder arrangement (1) comprises a retarder rotor (7), a retarder transmission (9), a lubricant feed conduit (11) arranged to conduct lubricant to the retarder transmission (9), a coupling device (13), and an actuator element (15). The actuator element (15) is moveable between an actuated position and an unactuated position to move the coupling device (13) between an engaged state and a disengaged state. The coupling device (13) is configured to, in the engaged state, connect the retarder rotor (7) to the shaft (3) via the retarder transmission (9), and in the disengaged state, disconnect the retarder rotor (7) from the shaft (3). The lubricant feed conduit (11) comprises a valve (17) mechanically connected to the actuator element (15). The present disclosure further relates to a transmission arrangement (40), a power train (50), and a vehicle (5).

Owner:SCANIA CV AB

External combustion engine and transmission mechanism thereof

InactiveCN102787942AReduce resistanceConstant volumeHot gas positive displacement engine plantsCombustionExternal combustion engine

The invention discloses an external combustion engine and a transmission mechanism thereof. The transmission mechanism of the external combustion engine comprises a connecting rod group and an oscillating rod group, wherein the connecting rod group includes a first connecting rod and a second connecting rod, the upper ends of the first connecting rod and the second connecting rod are hinged to a connecting rod neck of a crankshaft of the external combustion, the oscillating rod group includes a central oscillating rod and two side oscillating rods, the two side oscillating rods are symmetrically arranged on two sides of the central oscillating rod, the oscillating plane of the central oscillating rod is parallel to the oscillating planes of the two side oscillating rods, and the central oscillating rod and the side oscillating rods are coaxial with a pivot. The central oscillating rod is provided with a first hinge point and a second hinge point which are used for hinging a piston rod of a replacement piston, and the distance between the first hinge point and the pivot is equal to that between the second hinge point and the pivot. The side oscillating rods are respectively provided with a third hinge point and a fourth hinge point which are used for hinge a piston rod of a power piston, and the distance between the third hinge point and the pivot is equal to that between the fourth hinge point and the pivot. The lower end of the second connecting rod is hinged to a fifth hinge point, on the first side of the pivot, of the side oscillating rods, and the lower end of the first connecting rod is hinged to a sixth hinge point, on the second side of the pivot, of the side oscillating rods. By the transmission mechanism of the external combustion engine, distance between two air cylinders can be shortened.

Owner:杨永顺

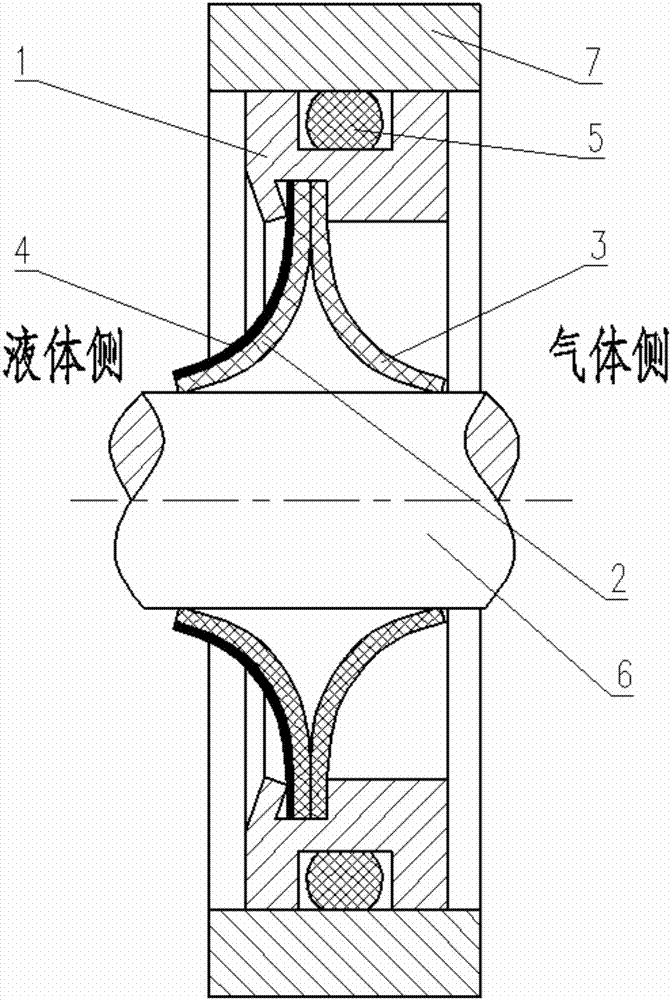

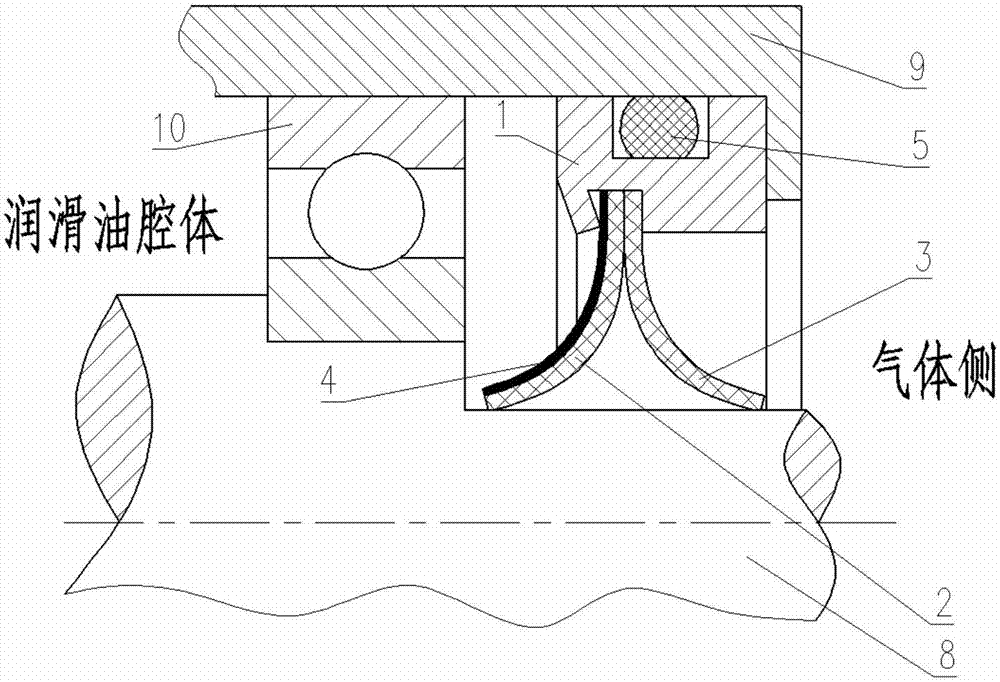

A Rotary Sealing Structure Capable of Two-way Sealing

Owner:CHINA NORTH VEHICLE RES INST

Positive displacement air compressor with folded blade type swing mechanism

InactiveCN105626527ASimple structureReduce vibrationRotary piston pumpsRotary piston liquid enginesAir compressionEngineering

The invention discloses a positive displacement air compressor with a folded blade type swing mechanism. The swing mechanism comprises a columnar rotor, folded blades and supporting sliding blocks. Folded blade placing grooves are axially formed in the outer side wall of the columnar rotor. The folded blades are arc-shaped blades, and the radian of the inner side faces of the folded blades is matched with the radian of the folded blade placing grooves. The supporting sliding blocks are arranged at the two ends of each folded blade placing groove correspondingly. The two side edges of each folded blade are hinged to the columnar rotor and the supporting sliding blocks correspondingly. The supporting sliding blocks are embedded into rotary sliding rings which are coaxial with a working cavity through embedding grooves. End caps are arranged at the two ends of the working cavity. An eccentric bearing is arranged in the center of each end cap. Supporting shafts are arranged at the two ends of the columnar rotor. The swing mechanism is inserted into the working cavity to make the supporting shafts penetrate through the rotary sliding rings to be fixed to the eccentric bearings in the centers of the end caps in an inserted mode. According to the positive displacement air compressor, through the structural design of the swing mechanism, the columnar rotor and the supporting sliding blocks are in a non-concentric rotation state during rotation, and the purposes of inlet-air compression and exhausting are achieved by forming a changeable volume cavity in a stator shell.

Owner:郎槟

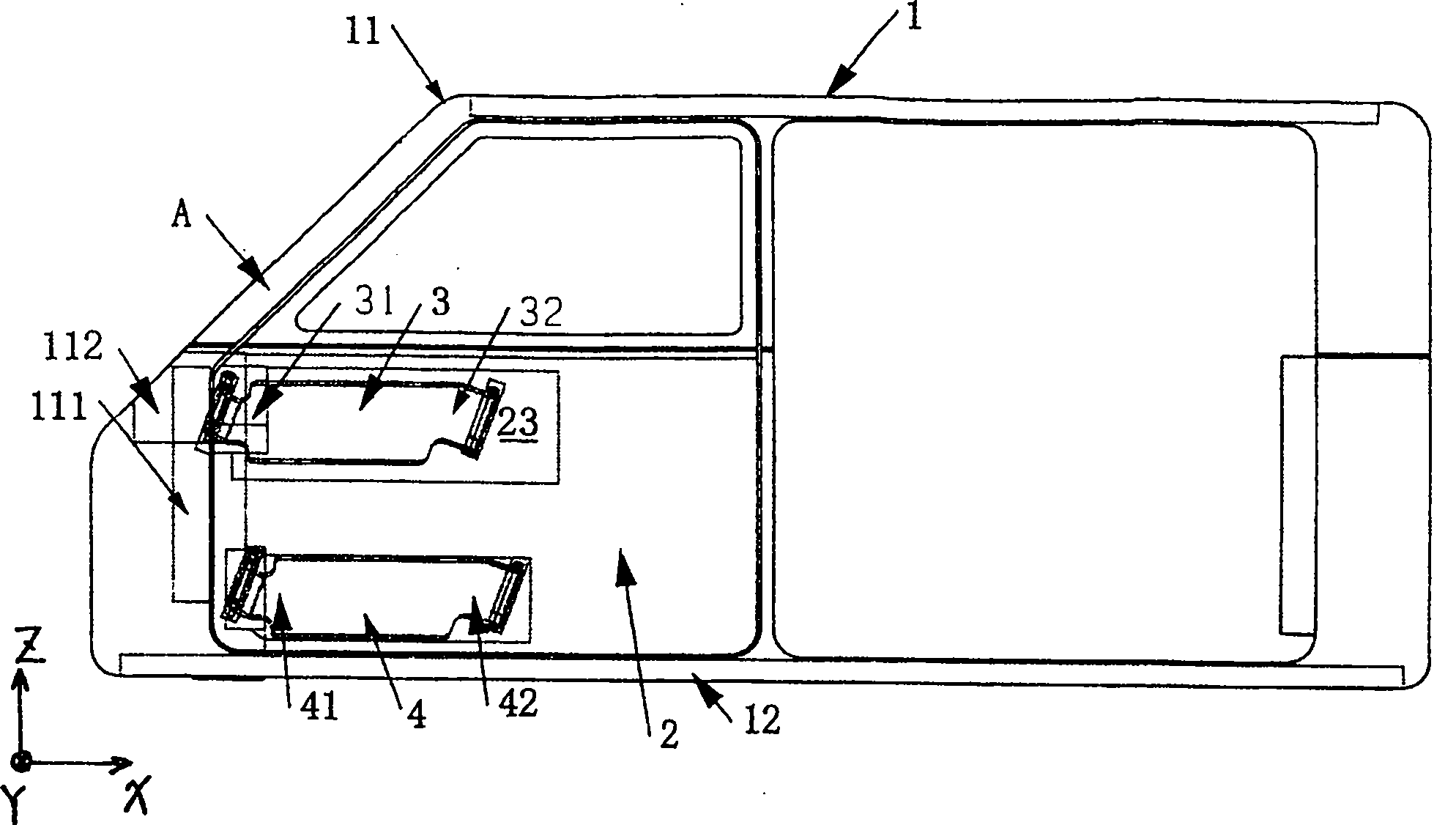

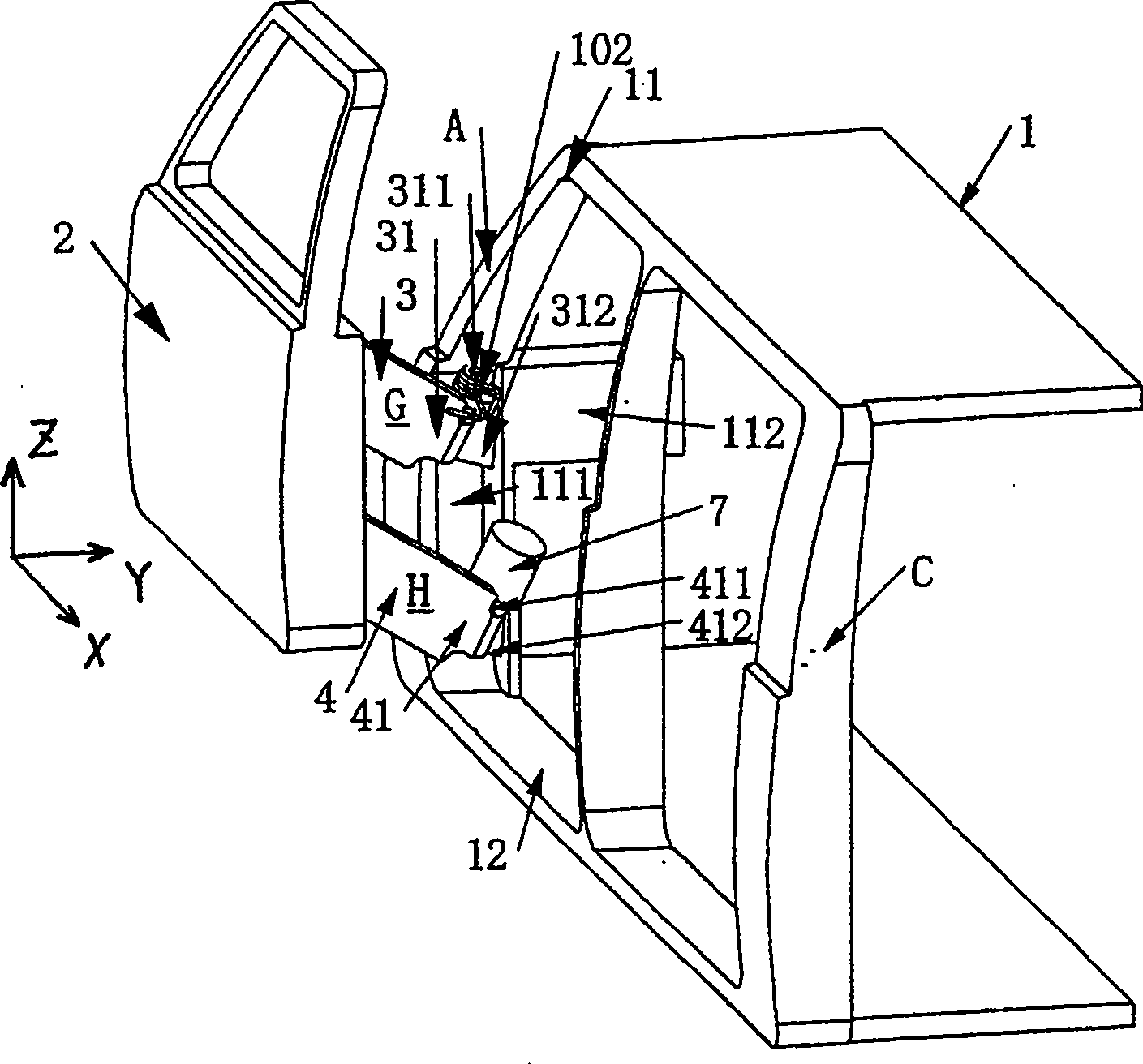

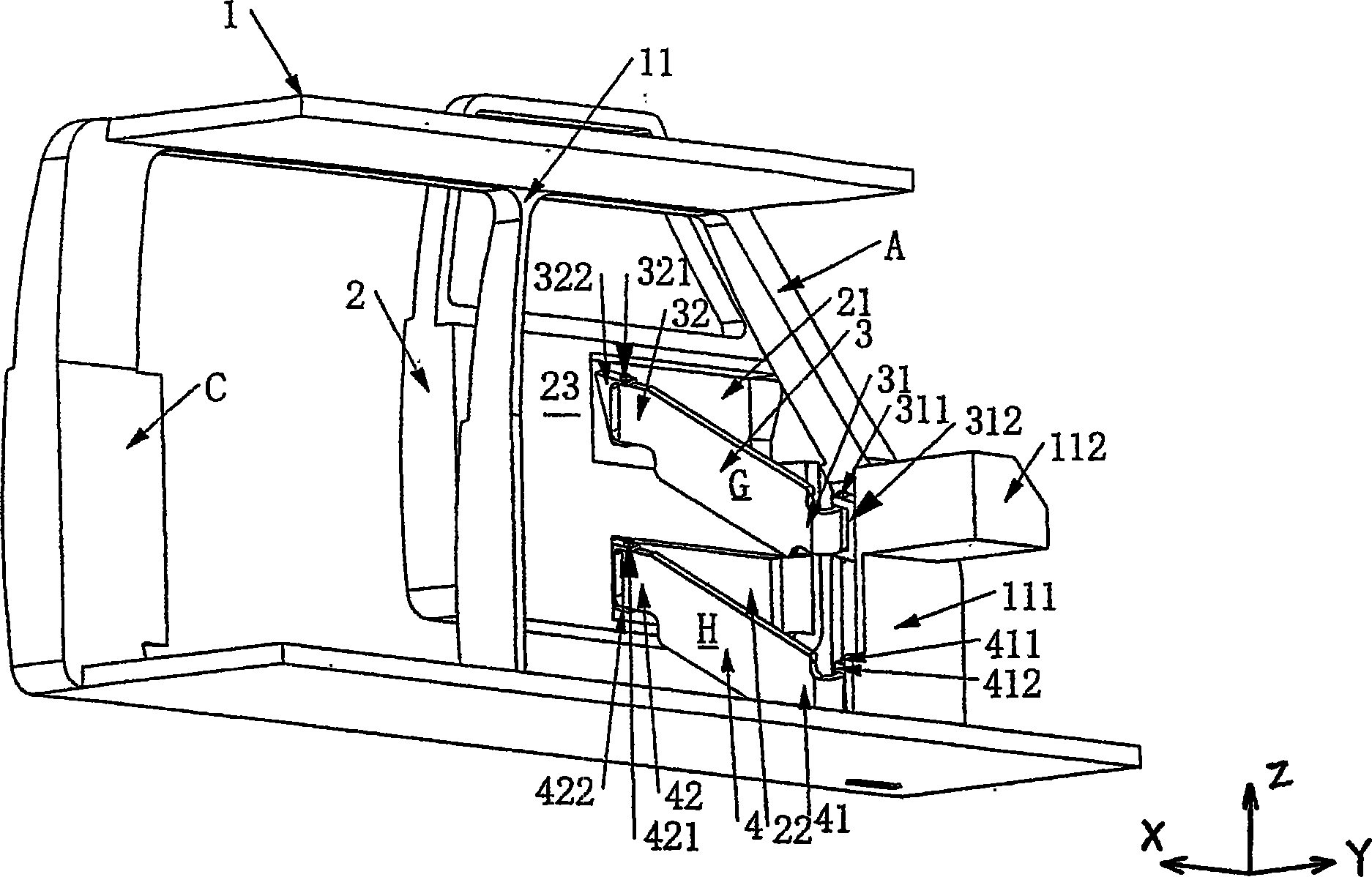

Three dimensional hinge system for vehicle door

The invention relates to a field of a linkage mechanism for vehicle doors and a body frame, and provides a simple and stable three-dimensional hinge system for the vehicle doors which occupies less space and adapts to all kinds of vehicle. This invention includes the body frame and vehicle doors, which are hinged to the doorframe of the body frame. The invention also includes a master connecting lever that comprises a first end that connects to the doorframe and a second end that connects to the inside of the door, a articulated connecting lever that comprises a first end that connects to thebody frame and a second end that connects to the door.

Owner:冯志德 +1

External combustion engine and transmission mechanism thereof

InactiveCN102182582BEasy to startReduce resistanceHot gas positive displacement engine plantsGas cylinderReciprocating motion

The invention discloses an external combustion engine and a transmission mechanism thereof. The external combustion engine comprises two groups of hot gas components, a transmission mechanism and a crank shaft, wherein each group of the hot gas components comprises a gas cylinder, a heater, a reheater and a cooler; a power piston replacement piston is arranged in the gas cylinder, and a cold cavity and a hot cavity are formed in the gas cylinder; the transmission mechanism comprises a connecting rod group and a swing rod group; the swing rod group comprises a center swing rod and edge swing rods; piston rods are hinged at two ends of the swing rod group respectively; a plane on which the center swing rod is placed and the planes on which the edge swing rods are placed are parallel to each other and coaxial with each other on a pivot shaft; the connecting rod group is surrounded by four connecting rods which are hinged between the pivot shaft and a crank shaft connecting rod neck; the first connecting rod and the second connecting rod are as long as each other and keep complementary angles from 30 to 60 degrees with the center swing rod and the edge swing rods; the third connecting rod and the fourth connecting rod are as long as each other, and the upper ends of the third connecting rod and the fourth connecting rod are hinged with each other; and a heat source heats the heater so that gas in a gas channel is expanded and contracted due to a reciprocating motion between a cold cavity and a hot cavity, and the crank shaft is driven by the transmission mechanism to do a periodic motion and work. The external combustion engine is easy to start and has low cost.

Owner:杨永顺

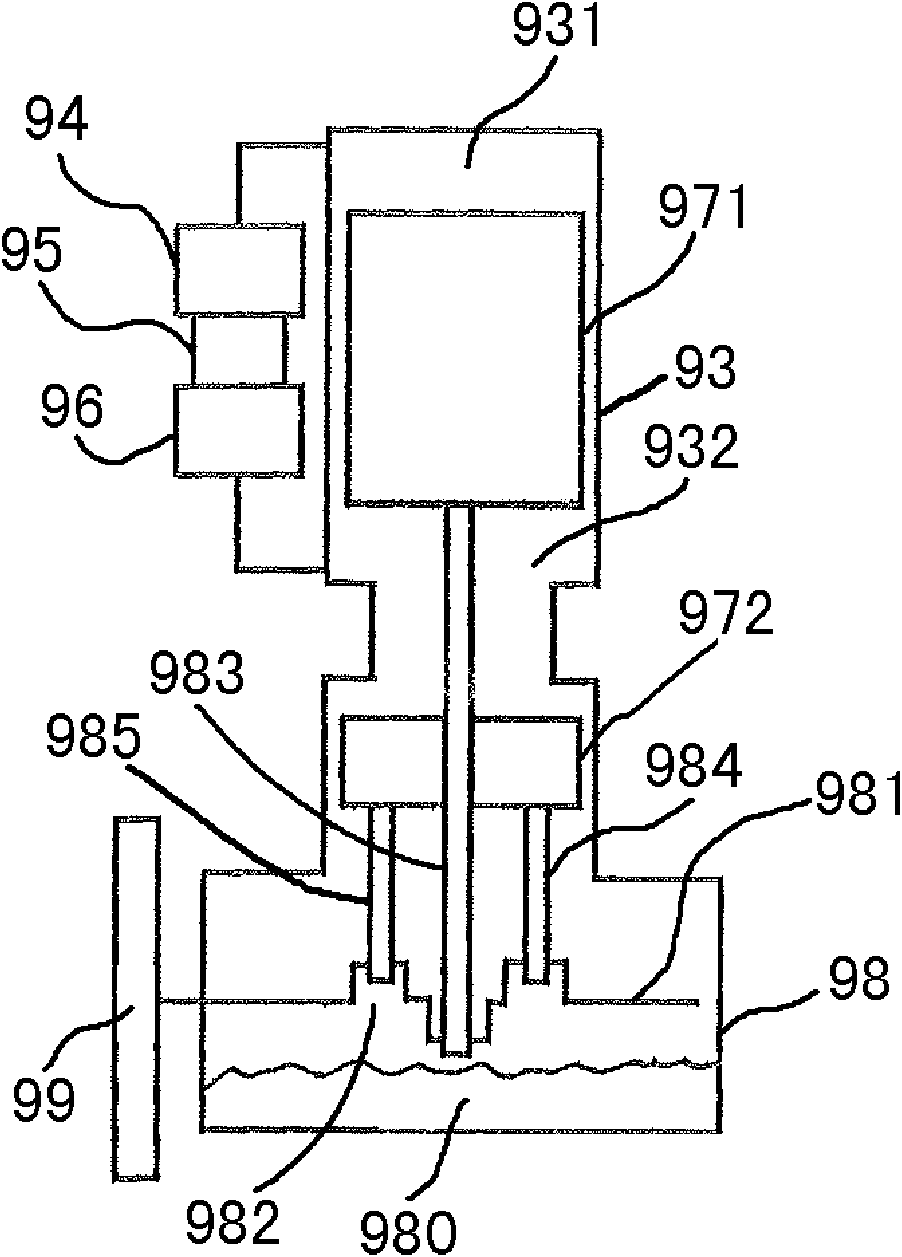

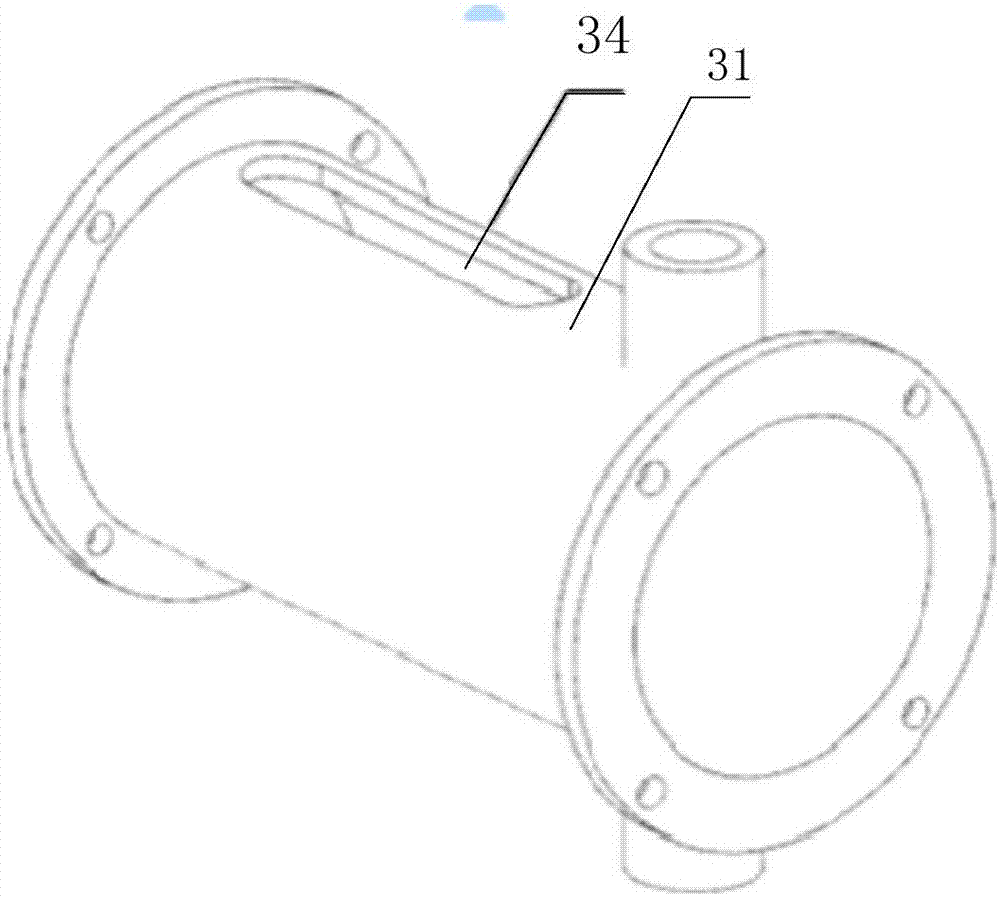

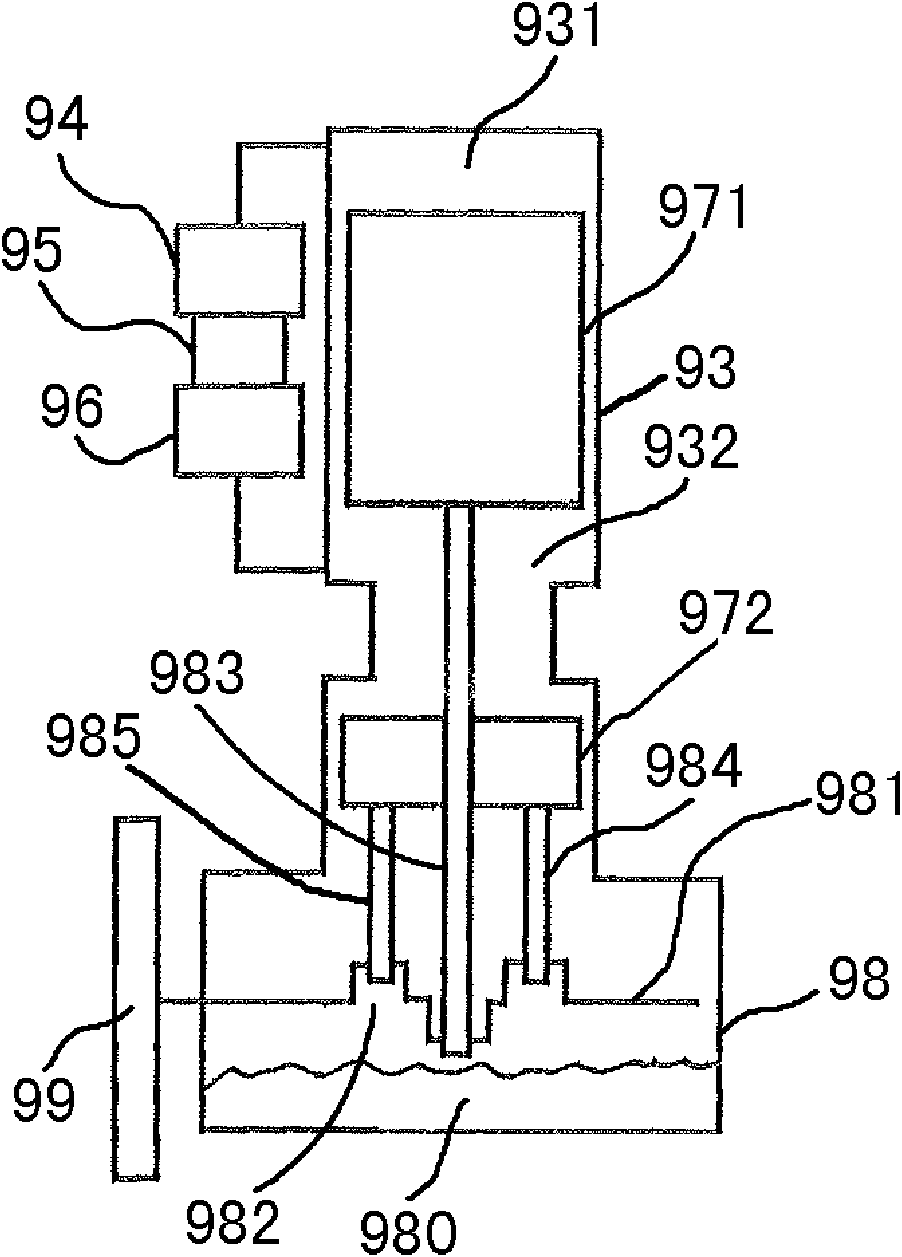

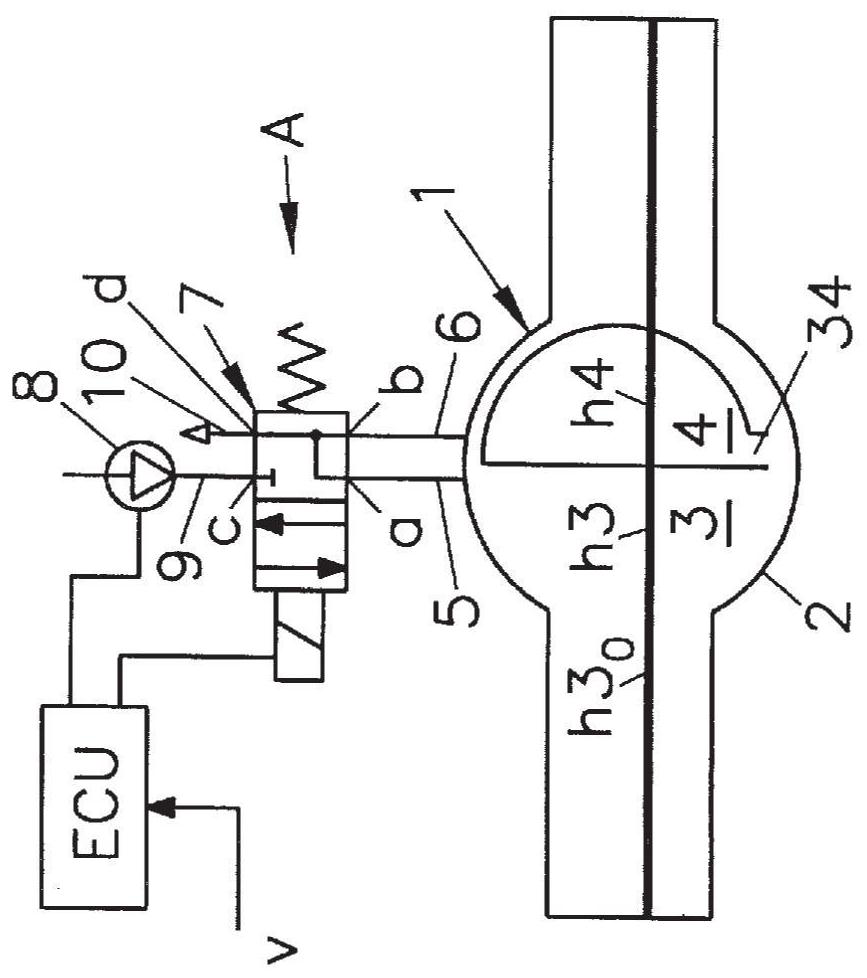

Method of controlling oil level in a gearbox and gearbox for implementing said method

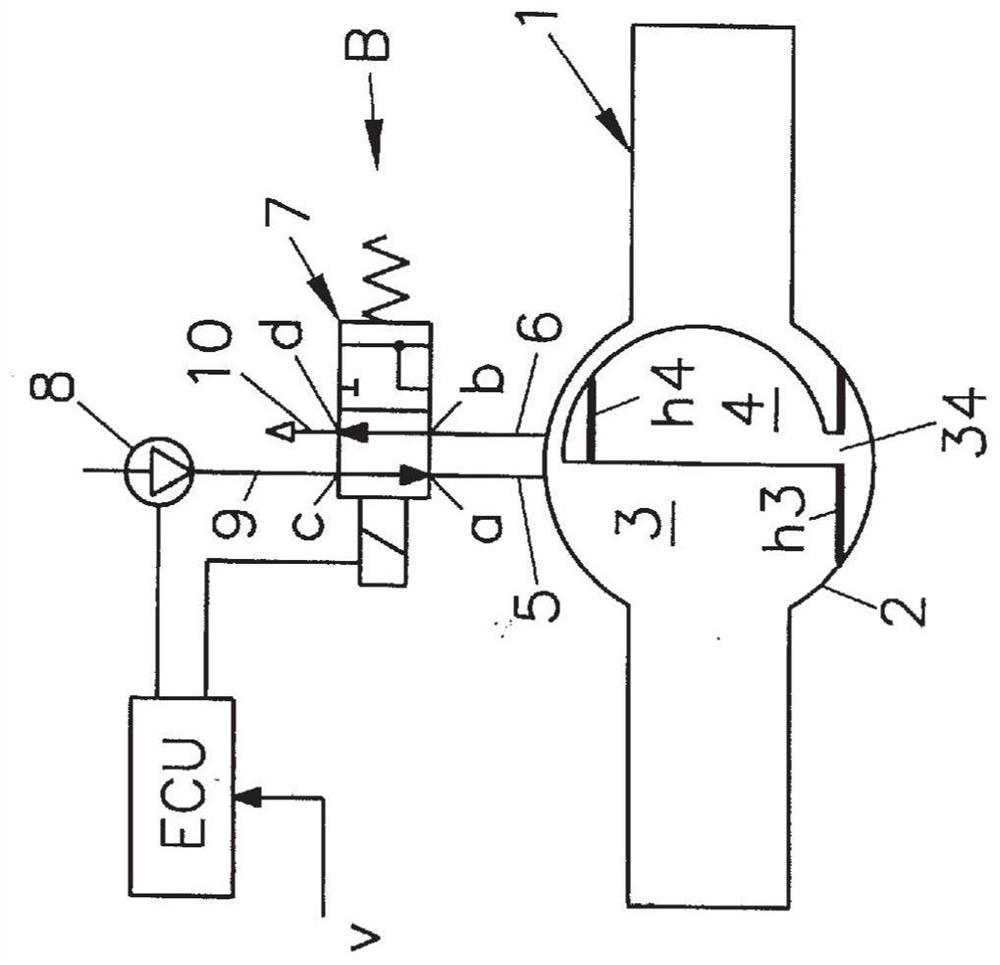

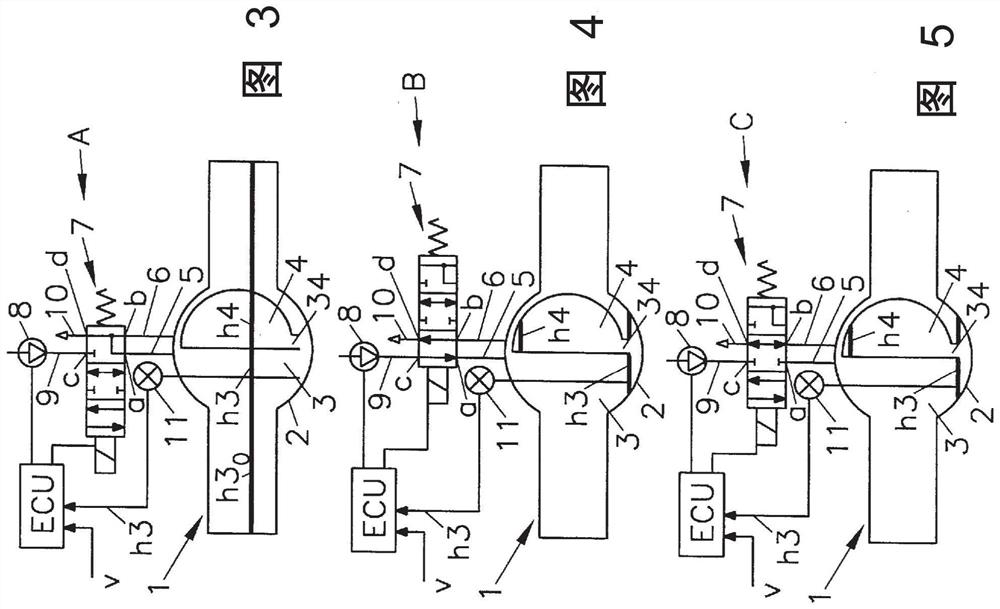

ActiveCN108027038BFully lubricatedChurn Loss AvoidanceGear lubrication/coolingLine tubingControl valves

The invention relates to a method for controlling the oil level (h3) in a differential gearbox of a vehicle having an oil sump (3) and an oil reservoir (4) pneumatically separated from the oil sump (3). The oil reservoir (4) is connected to the oil sump (3) through at least one oil passage (34), and the oil sump (3) is connected to a pneumatic pressure source (8) through at least one control valve (7) and an air line (5), wherein In at least one position (B) of the control valve (7), the pressure source (8) is pneumatically connected to the oil sump (3). To improve efficiency, at least one first characteristic operating parameter of the vehicle is detected according to the invention and the control valve (7) is operated at least according to said first characteristic operating parameter, wherein vehicle speed (v) is selected as the first characteristic operating parameter.

Owner:AVL LIST GMBH

A sliding vane compressor whose cylinder rotates with the rotor

ActiveCN108194357BImprove efficiencySolve wear and tearRotary piston pumpsRotary piston liquid enginesFriction lossPneumatic cylinder

Owner:SOUTHEAST UNIV

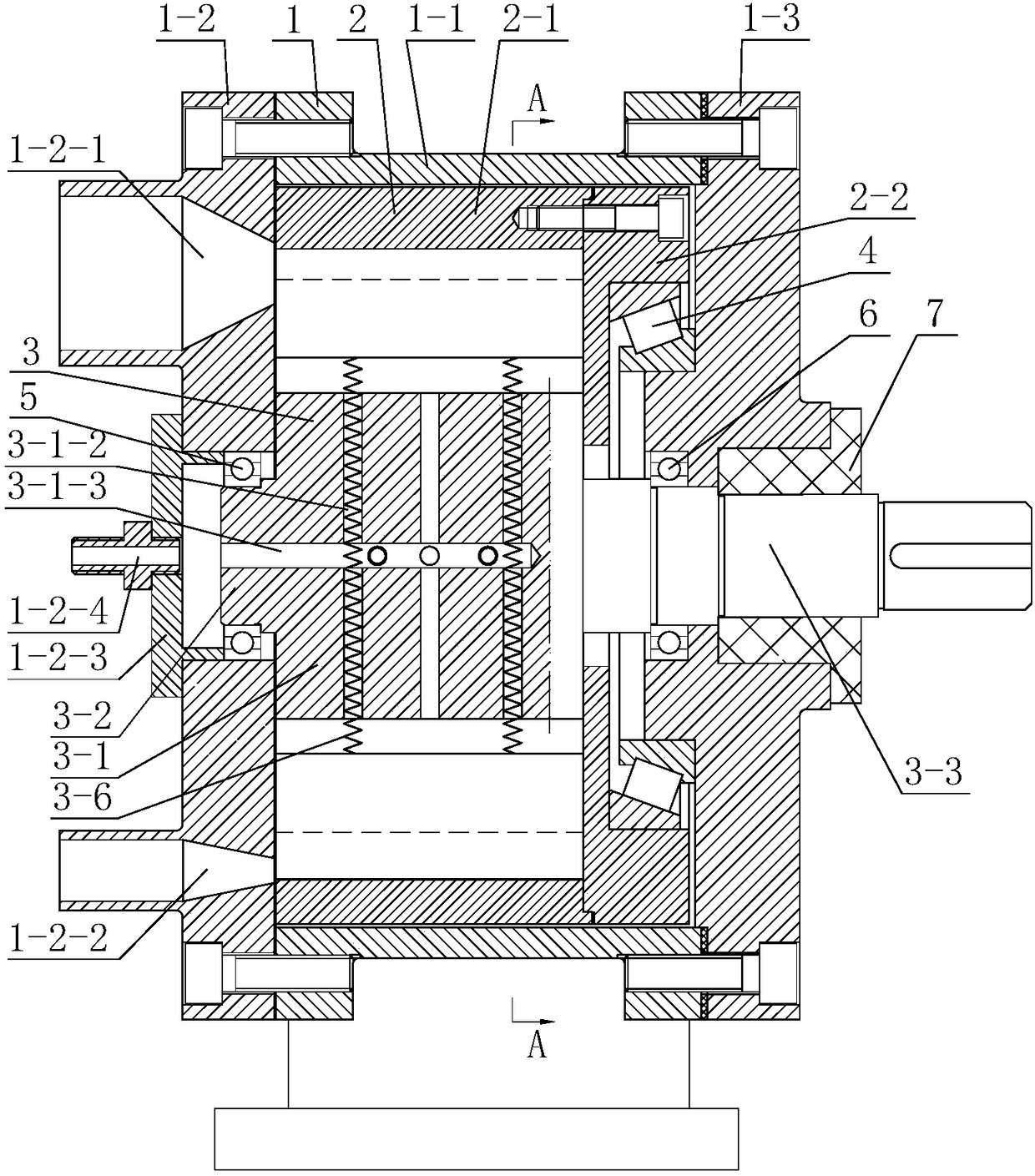

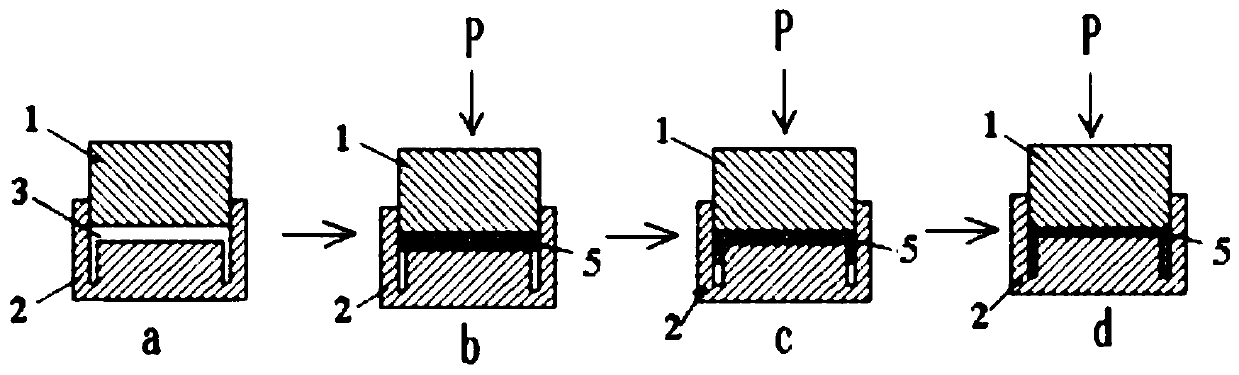

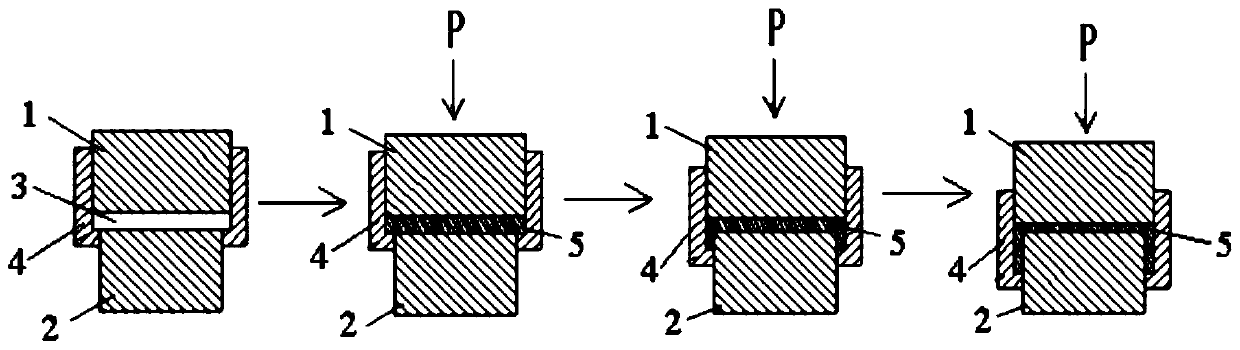

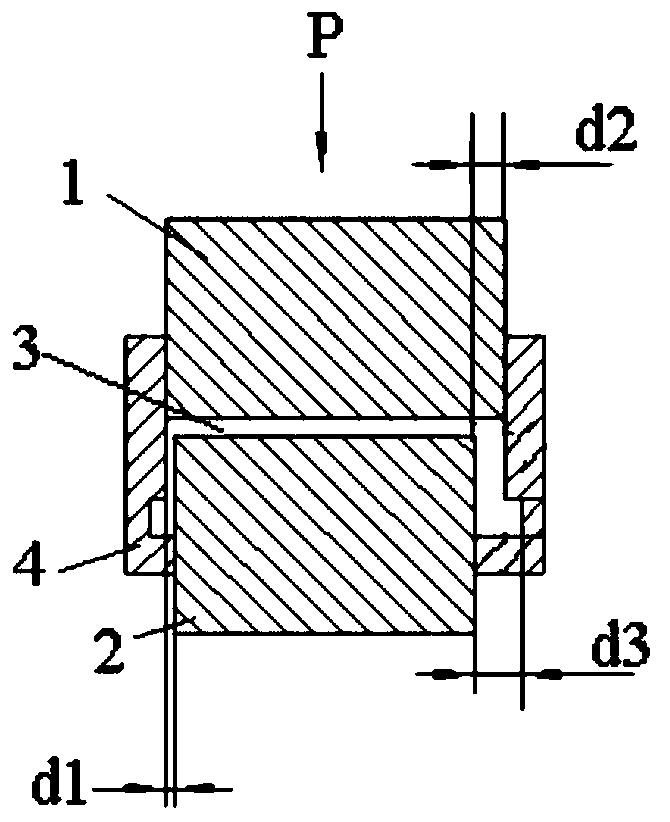

A pressure forming device and a pressure forming method

ActiveCN108067574BUniform flowUniform qualityForging/hammering/pressing machinesRelative motionMachining

The invention discloses a pressure forming device and method and belongs to the technical field of metal workpiece machining. The pressure forming device and method are designed for solving the problems that forming is difficult and the workpiece texture is nonuniform due to the fact that the blank flowing path is excessively long in an existing device and method. The pressure forming device comprises an upper die, a lower die and a movable die. The upper die and the lower die are arranged oppositely and can move oppositely; the movable die is inserted into the lower die and / or arranged outside the upper die and the lower die in a sleeving mode, and the movable die can move up and down relative to the upper die and the lower die; and a die cavity is defined by the upper die, the lower dieand the movable die jointly, and in the forming process, the movable die moves relative to the upper die and the lower die so as to dynamically increasing the size of the die cavity. According to thepressure forming device and the pressure forming method based on the pressure forming device, the size of the die cavity can be dynamically increased, the blank flowing path is short and balanced, flow lines are uniform and stable, and the workpiece texture is uniform.

Owner:INNER MONGOLIA WENDING TECH CO LTD

Chain transmission type ridge crushing box

InactiveCN104675941ALow lubrication requirementsEasy to processGearingTilling equipmentsCouplingAgricultural engineering

The invention discloses a chain transmission type ridge crushing box, which comprises a box body, a driving chain wheel, a driven chain wheel, a chain, a bearing cover, a shaft, a bearing, a box body with a bearing seat, and a coupling, wherein the driving chain wheel is fixedly connected with a power source, the shaft and the chain wheel are coaxially and fixedly connected, and are fixedly arranged on the bearing seat of the box body through bearing support, the bearing cover is connected with the bearing seat through a fastener, the driven chain wheel is connected with the driving chain wheel through the chain, and the coupling is connected with a spiral drill bit. The chain transmission type ridge crushing box has the advantages that the lubricating requirement is lower, the sealing of the box body is not needed, the processing is convenient, the interchangeability is good, and the assembly and maintenance are convenient; the deep tillage and loosening effects of soil can be further improved, and more air can exist in the soil.

Owner:GUANGXI WUFENG MACHINERY CO LTD

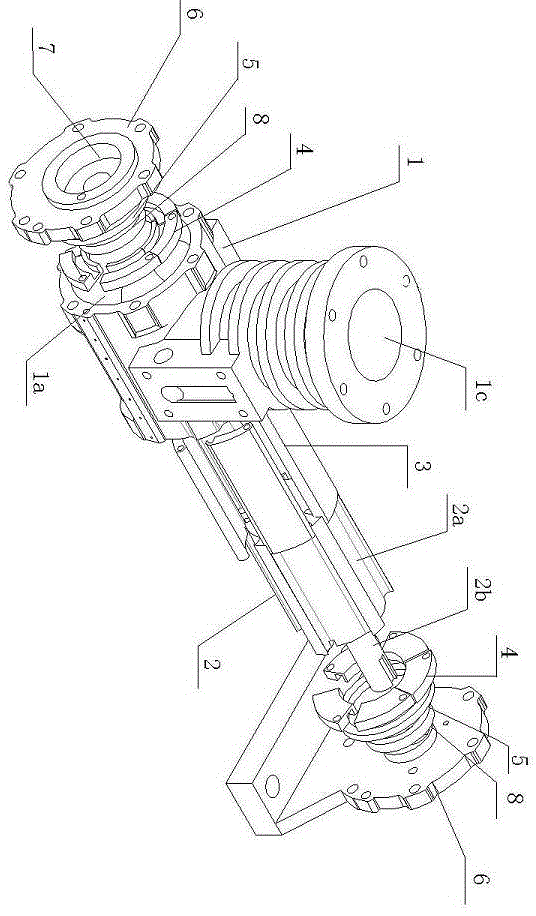

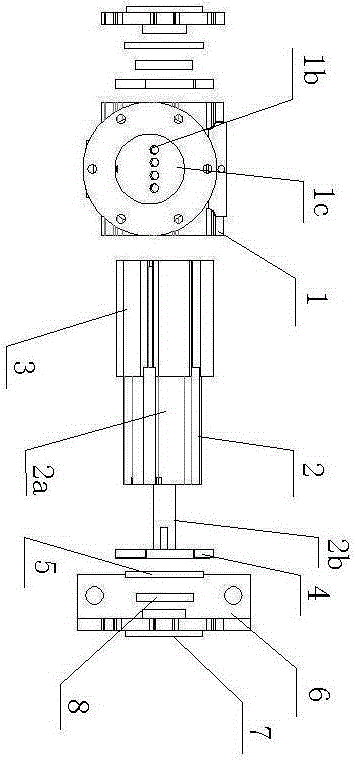

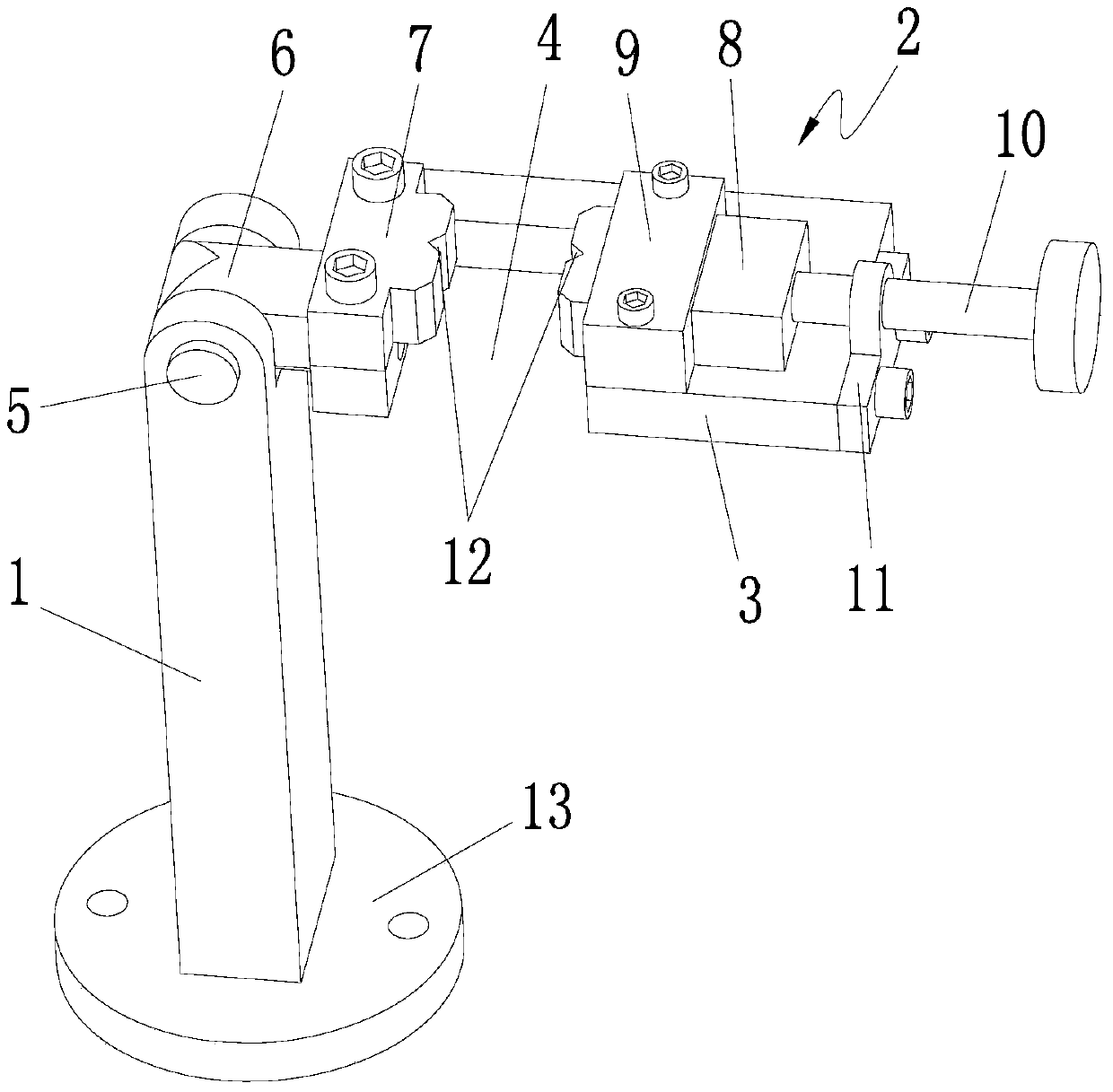

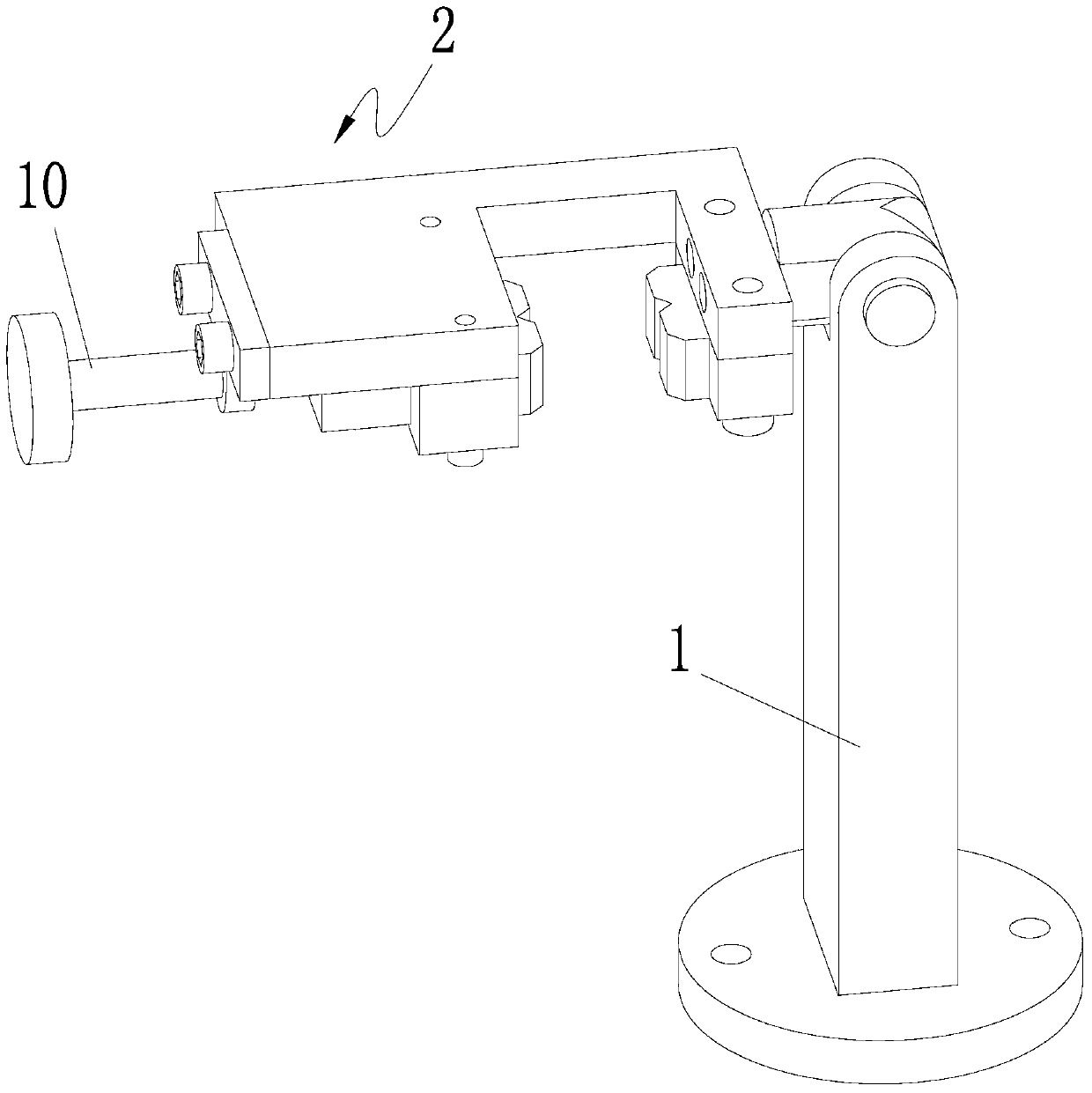

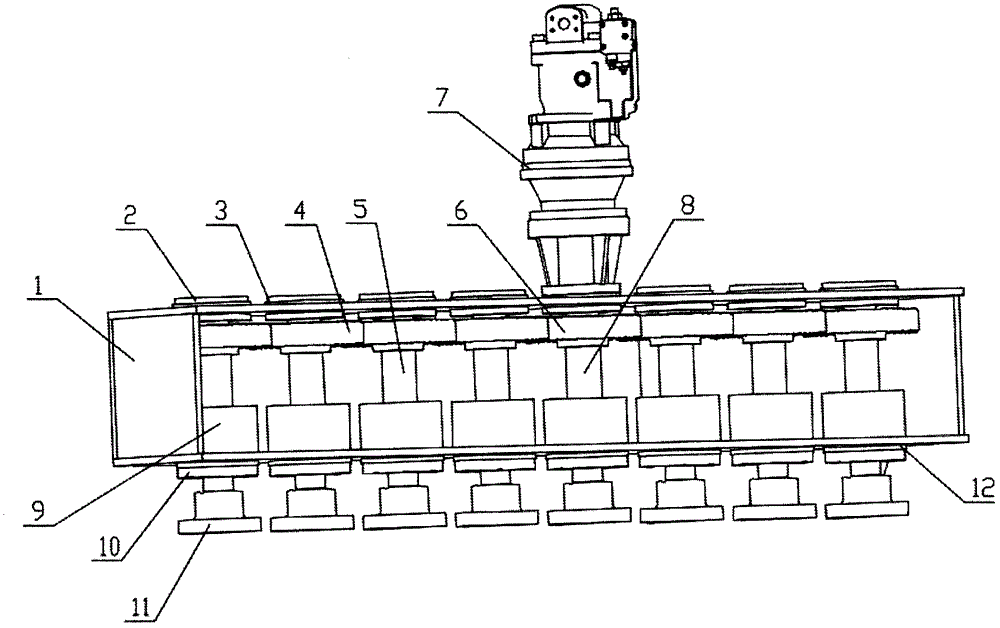

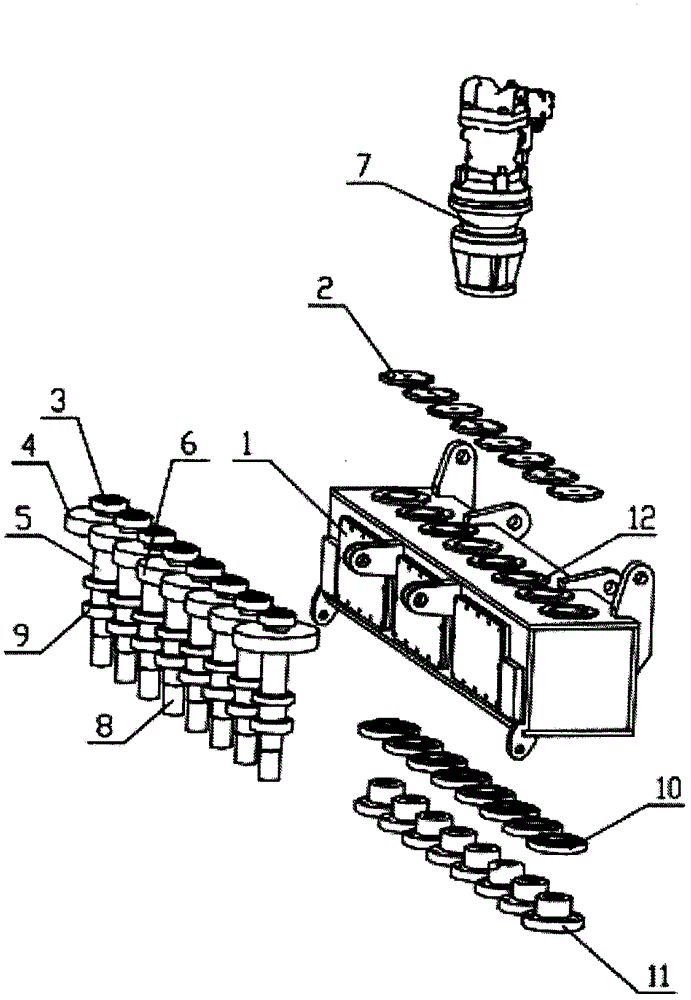

A fuel injector disassembly test bench

ActiveCN104929839BQuick flipLow lubrication requirementsEngine testingFuel injection apparatusLower limitCantilever

Owner:SOUTH CHINA UNIV OF TECH

Pulse knock rotor spindle engine

InactiveCN101338702BIncrease useSingle purposeTurbine/propulsion engine coolingGas turbine plantsHigh pressureSubmarine

The present invention relates to a pulse detonation rotor shaft engine. In the technical proposal, the pulse detonation rotor shaft engine mainly consists of a pulse detonation engine, a rotor and an output shaft; propulsive gas with the high temperature and high pressure expansion of pulse which is ejected when the pulse detonation engine works is used as a power source to push the rotor to rotate; the rotor drives the output shaft to rotate; a pulse detonation rotor shaft engine uses the output shaft to output most energy produced by the pulse detonation engine by outputting torsion continuously; the output shaft drives various kinds of loads to work. The pulse detonation rotor shaft engine has the beneficial effects as follows: firstly, the pulse detonation rotor shaft engine can be used as a shaft engine to be widely applied in various kinds of dynamic systems, such as ship, submarine, tank, tractor, automobile, train, and the like and has wide purposes; secondly, the pulse detonation rotor shaft engine overcomes the disadvantage of the large noise of the prior pulse detonation engine; thirdly, compared with a piston type engine, the pulse detonation rotor shaft engine has theobvious advantages of simple structure, low cost, high reliability, long service life, light weight, less fraction resistance loss, etc.

Owner:RUGAO HUAYANG ALUMINUM PROD

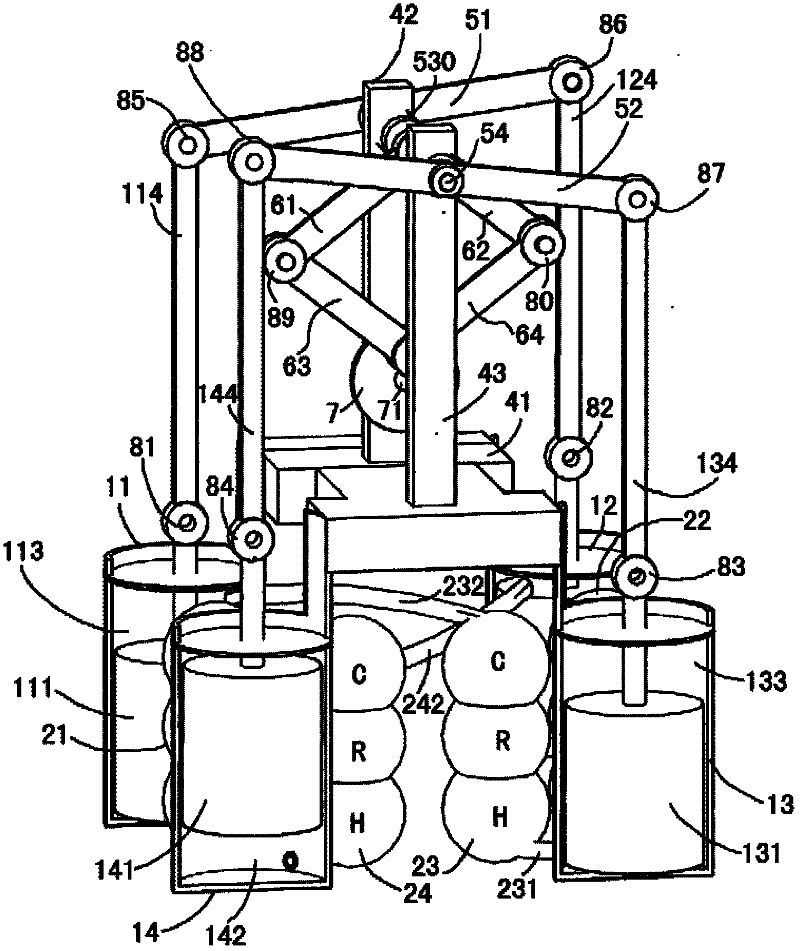

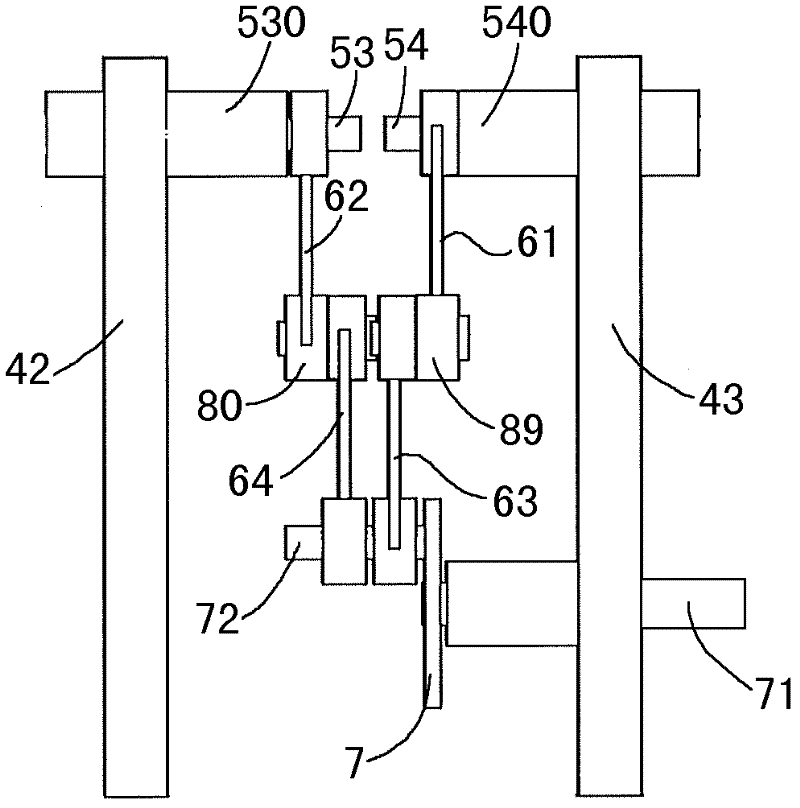

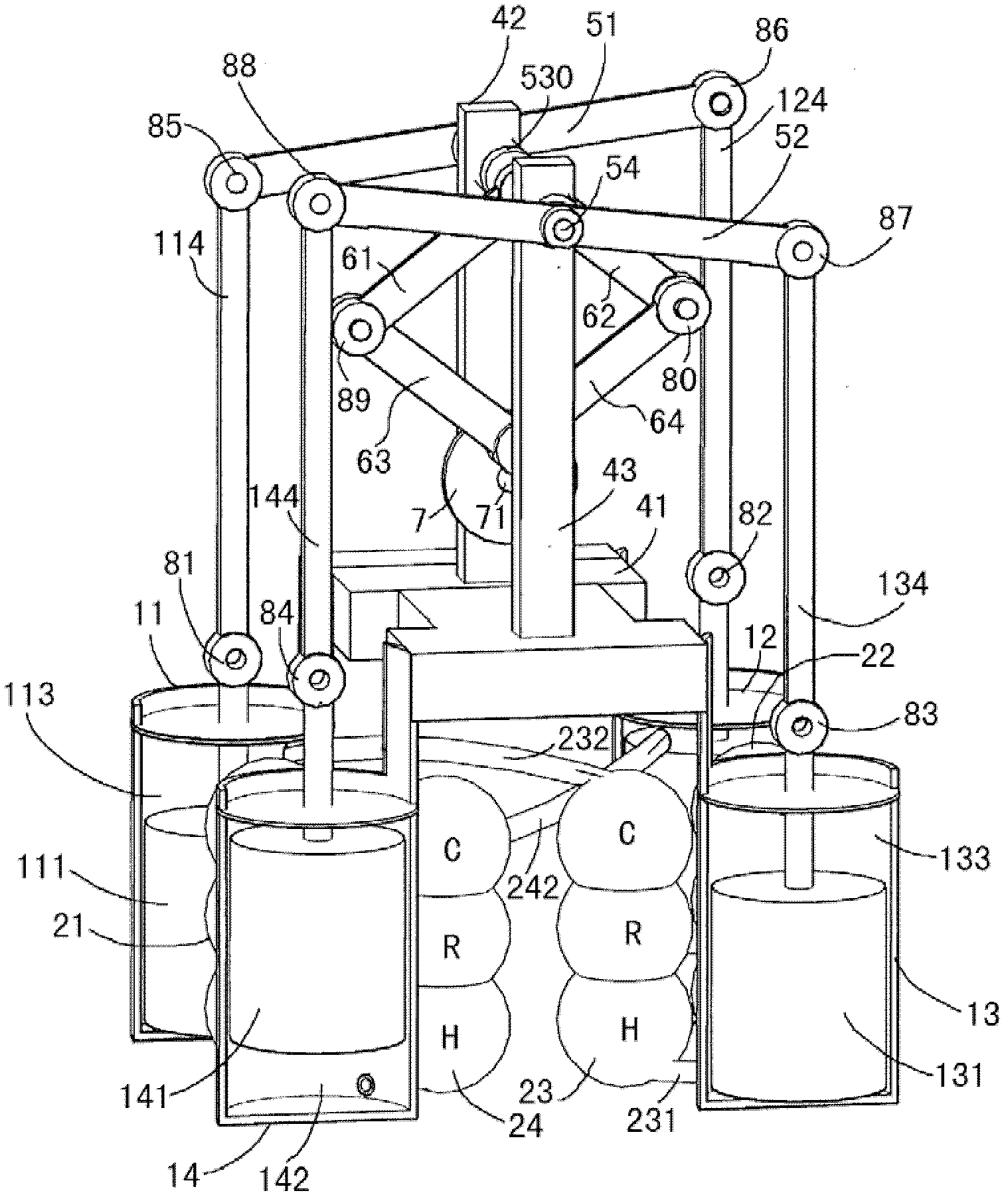

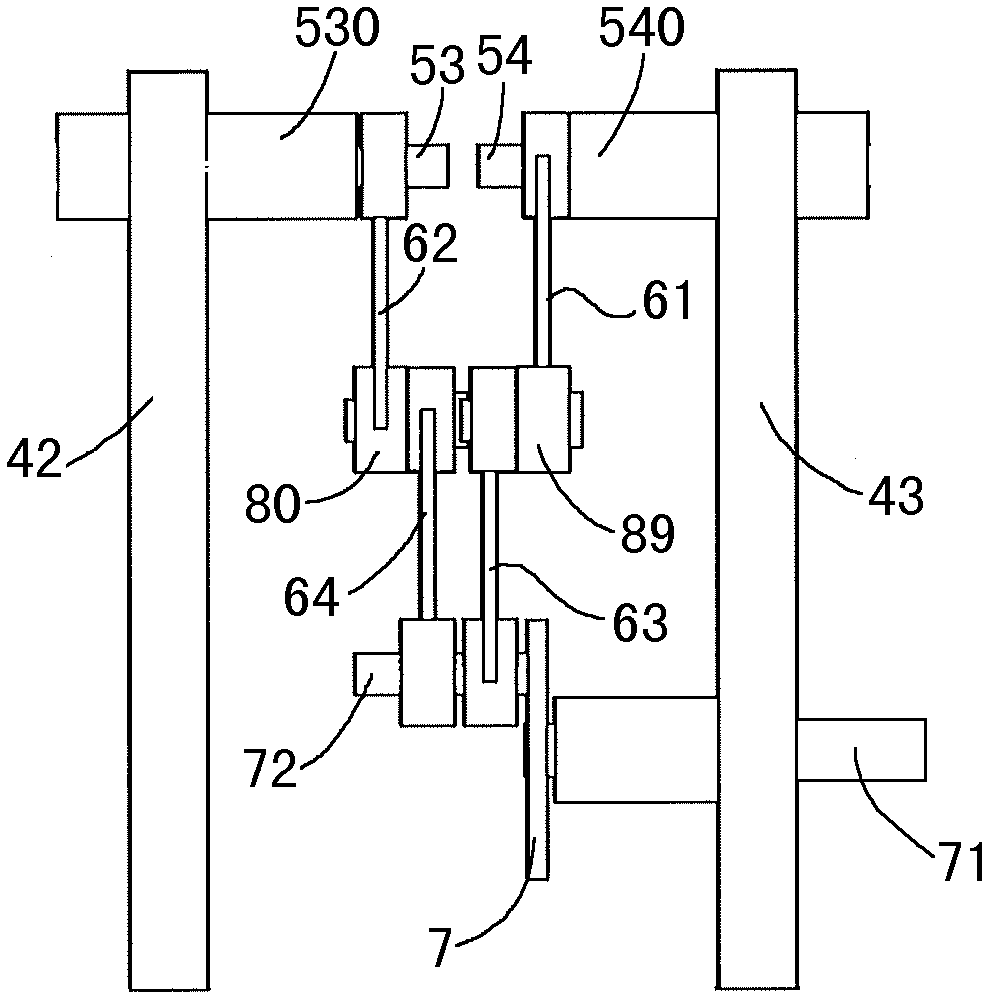

External combustion engine and transmission mechanism thereof

InactiveCN102251877BGuaranteed transmission effectLow costGearingEngine componentsExternal combustion engineInternal combustion engine

An external combustion engine comprises a hot gas assembly, a transmission mechanism and a crankshaft (7). The hot gas assembly comprises four heater / regenerator / cooler (HRC) groups and four cylinders (11, 12, 13, 14), said cylinders being arranged in a rectangular array. Each cylinder is provided with a hot chamber (112, 122, 132, 142) and a cool chamber (113, 123, 133, 143). The hot chamber and cool chamber are not in communication with each other. Each hot chamber is in communication with one HRC group and with a cool chamber gas conduit of another cylinder, thereby forming a gas passage. The transmission mechanism comprises a set of swing rods and a set of connecting rods, wherein the set of swing rods comprises a first swing rod (51) and a second swing rod (52) in mutually parallel swing planes, and wherein the set of connecting rods comprises four connecting rods. A first connecting rod (61) and a second connecting rod (62) having the same length extend downwards or upwards from a second pivot shaft (54) and a first pivot shaft (53), respectively. The upper ends or the lower ends of a third connecting rod (63) and a fourth connecting rod (64) having the same length are hinged with the first connecting rod (61) and the second connecting rod (62), respectively, whereas the lower ends or the upper ends thereof are hinged with a connecting rod neck (72) of the crankshaft (7). The external combustion engine is low in cost and easy to manufacture.

Owner:杨永顺

Planetary Roller Bearings

ActiveCN105805239BIncrease speedImprove efficiencyRolling contact bearingsToothed gearingsRolling-element bearingEngineering

The invention discloses a planetary roller bearing, relates to the field of mechanical bearings, in particular to a high-speed precise heavy-duty bearing. Two sets of planetary gears are utilized for replacing an ordinary rolling bearing retainer, and the problems that according to the ordinary bearing retainer, due to the fact that the retainer is rubbed and abraded during high-speed running, a rolling body bounces and deviates from the rolling direction, heating of a bearing is intensified, the load is low, and even the bearing is in failure are solved. The planetary roller bearing is the precise heavy-duty bearing high in rotating speed and efficiency, long in service life and high in stability, the lubricating requirement is lower than that of a conventional bearing, and the maintaining cost is low.

Owner:王福成

Friction wheel transmission type ridge crushing box

InactiveCN104663036ALow lubrication requirementsEasy to processTilling equipmentsCouplingAgricultural engineering

The invention discloses a friction wheel transmission type ridge crushing box, which comprises friction wheels, a bearing cover, a shaft, a bearing, a box body with a bearing seat, and a coupling, wherein the friction wheels comprise a driving friction wheel and a driven friction wheel, the driving friction wheel is fixedly connected with the power source, the shaft and the friction wheels are coaxially and fixedly connected, and are fixedly arranged on the bearing seat of the box body through bearing support, the bearing cover is connected with the bearing seat through a fastener, the adjacent friction wheels are mutually pressed, and the coupling is coupled with a spiral drill bit. The friction wheel transmission type ridge crushing box has the advantages that the lubricating requirement is lower, the processing is convenient, the interchangeability is good, and the assembly and maintenance are convenient; the deep tillage and loosening effects are further improved, and more air can exist in soil.

Owner:GUANGXI WUFENG MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com