Electromagnetic vibration power generation device

An electromagnetic vibration and power generation device technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of low power generation efficiency and low magnetic circuit utilization rate, and achieve the goal of improving magnetic circuit utilization rate, improving efficiency, and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

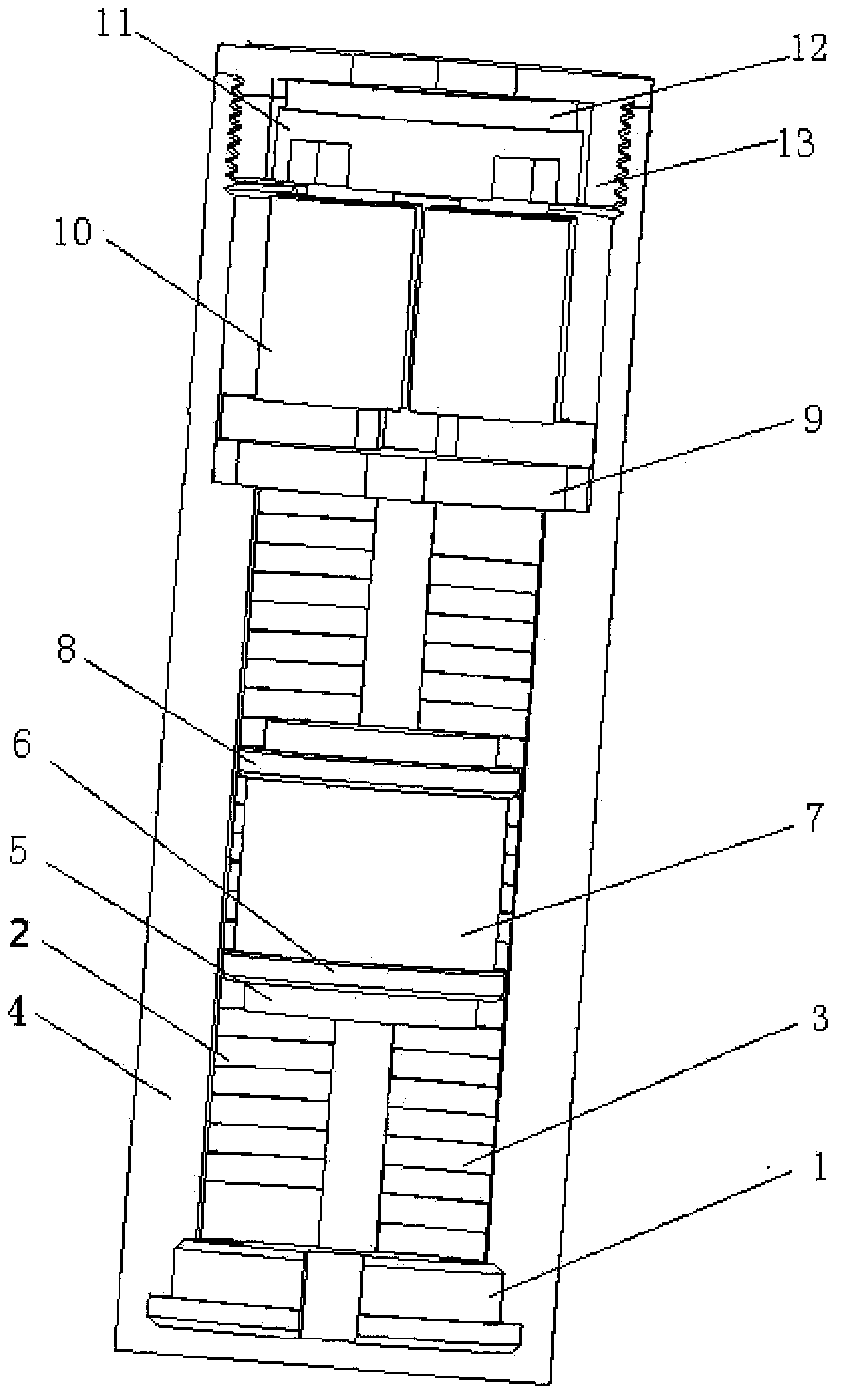

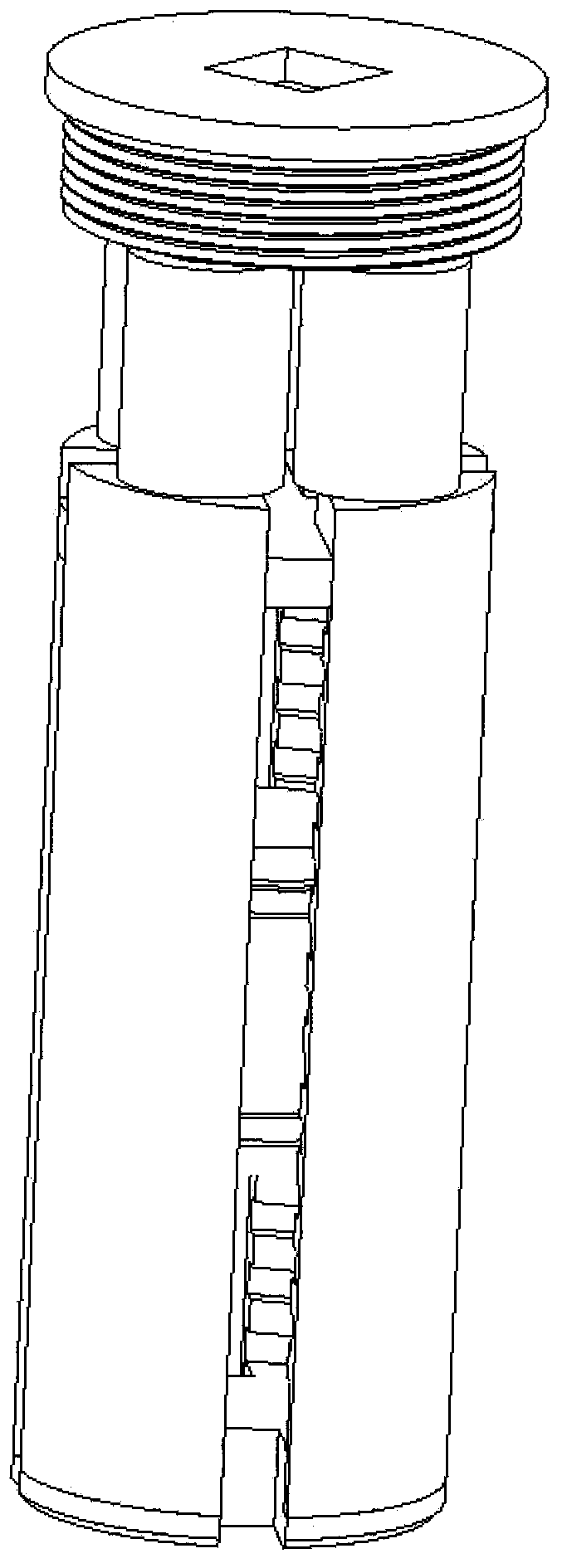

[0029] refer to Figure 1 to Figure 9 , an electromagnetic vibration power generation device, including a lower yoke bracket 1, two left and right yokes and two front and rear yokes 3, a shell 4, an upper and lower buffer 5, a lower armature 6, a permanent magnet 7, an upper armature 8, and an upper magnet Yoke bracket 9, induction coil 10, yoke top 11, rubber ring 12, top cover 13. The shell 4 is made of aluminum material and is cylindrical with a bottom, and four guide rails are evenly distributed on its inner wall; the lower yoke bracket 1 is made of aluminum material and is located at the bottom of the shell 4 , the lower yoke bracket 1 includes upper and lower parts, which are respectively composed of a middle cylinder and four fan-shaped blocks, and the fan-shaped block and the upper guide rail of the shell are mutually locked as the circumferential positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com