Planetary Roller Bearings

A roller bearing and planetary technology, applied in the field of high-speed precision heavy-duty bearings, can solve the problems of deviation from the rolling direction, increased heating of the bearing, and low load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

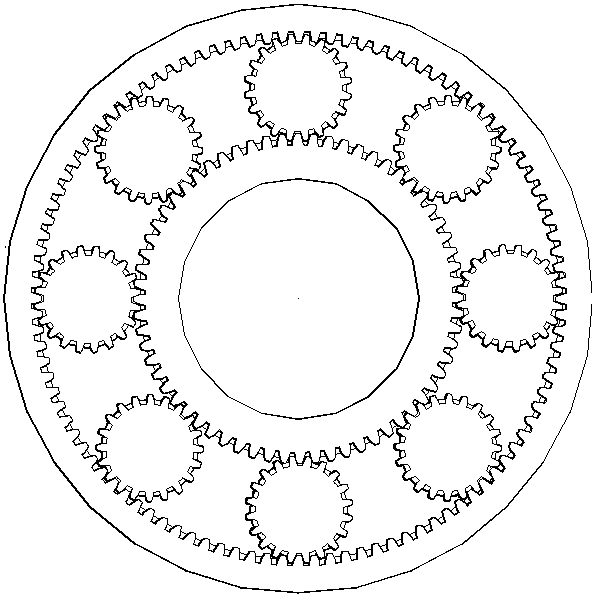

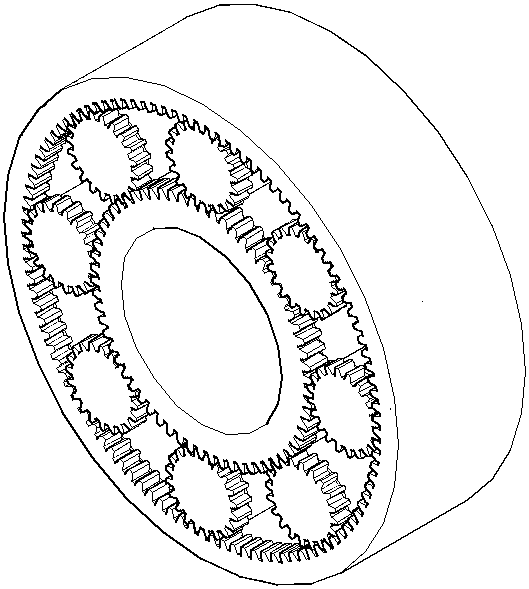

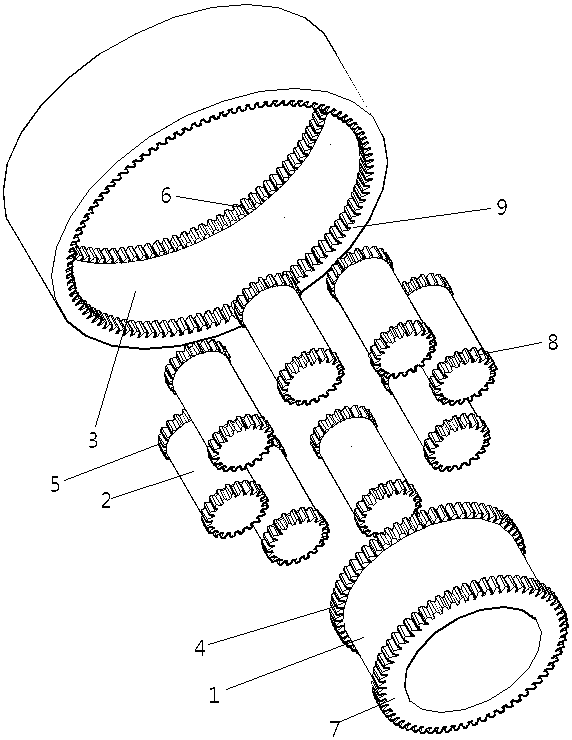

[0015] Planetary roller bearings are mainly composed of bearing outer rings, planetary rollers, and bearing inner rings. Planetary roller bearings have at least three planetary rollers.

[0016] Bearing outer ring is made up of left end outer ring gear 6, right end outer ring gear 9 and bearing outer ring raceway 3, and is fixed together or as a whole.

[0017] Planetary roller is made up of left-end planetary pinion 5, right-end planetary pinion 8 and middle roller 2 and is fixed together or as a whole.

[0018] Bearing inner ring is made up of left end sun gear 4, right end sun gear 7 and bearing inner ring raceway 1 and is fixed together or as a whole.

[0019] It is characterized in that a set of planetary gears work together at both ends of the planetary roller bearing, so that the two sets of planetary gears roll and mesh at the same time when the bearing is working, and at the same time, the roller 2 of the planetary bearing, the raceway 1 of the inner ring of the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com