Method of controlling oil level in a gearbox and gearbox for implementing said method

A gearbox and oil level technology, applied in gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve problems such as large agitation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

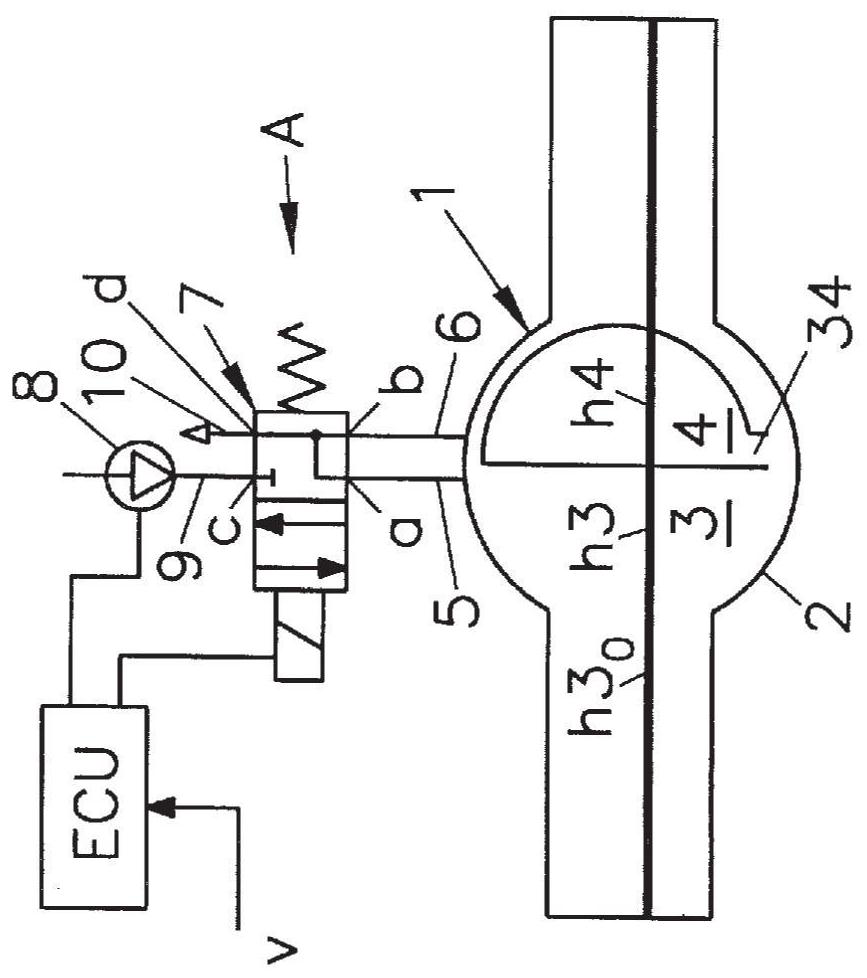

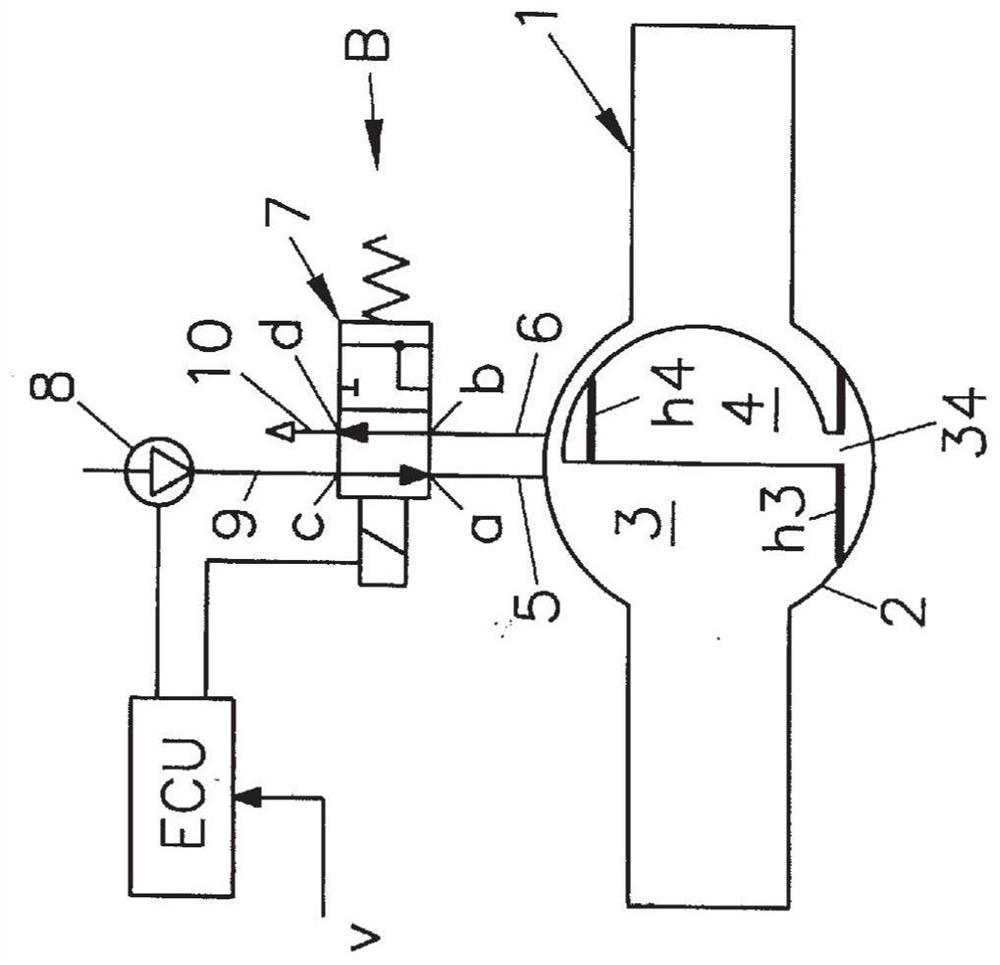

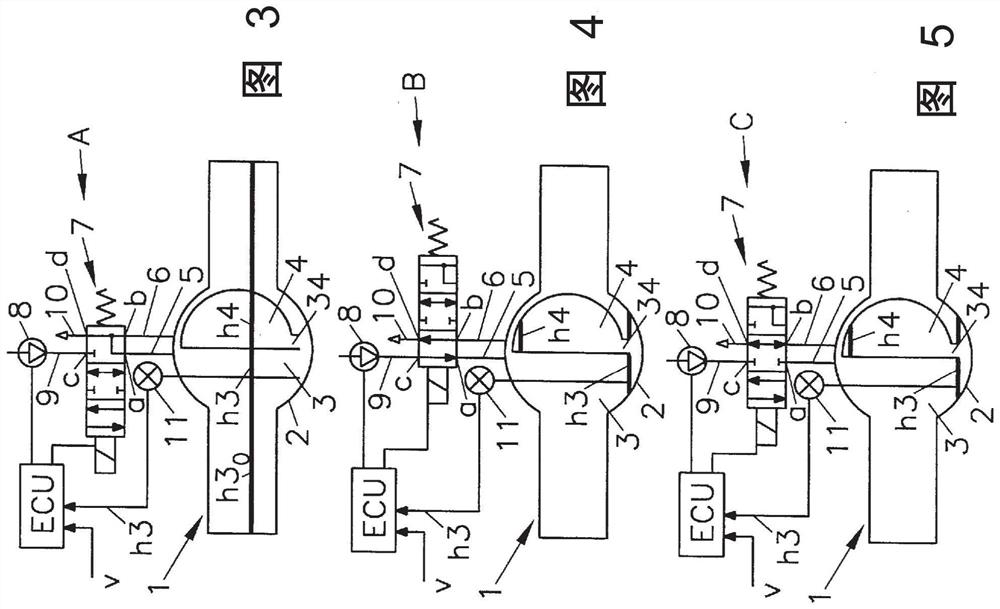

[0030] The figures respectively show a differential gearbox 1 of a vehicle, wherein two pneumatically separated compartments are arranged inside the housing 2 of the differential gearbox 1, namely an oil sump 3 and an oil sump hydraulically connected to each other by at least one oil channel 34 Oil reservoir 4. The first air line 5 leads into the oil sump 3 and the second air line 6 leads into the oil reservoir 4 , wherein the flow through the air lines 5 , 6 can be controlled by means of a control valve 7 . The control of the control valve 7 is performed by an electronic control unit ECU, which receives at least one characteristic operating parameter (eg vehicle speed v) as an input variable. The control valve 7 is in each case designed as a multi-way valve, wherein a first connection a is connected to the first air line 5, a second connection b is connected to the second air line 6, a third connection c is connected to the The pressure line 9 of the pressure source 8, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com