Straight-line piston fluid engine with wobble drive valve actuation

A technology of oscillating drive and piston, applied in the field of axial piston fluid engine, can solve the problems of high production cost, maintenance and lubrication of the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

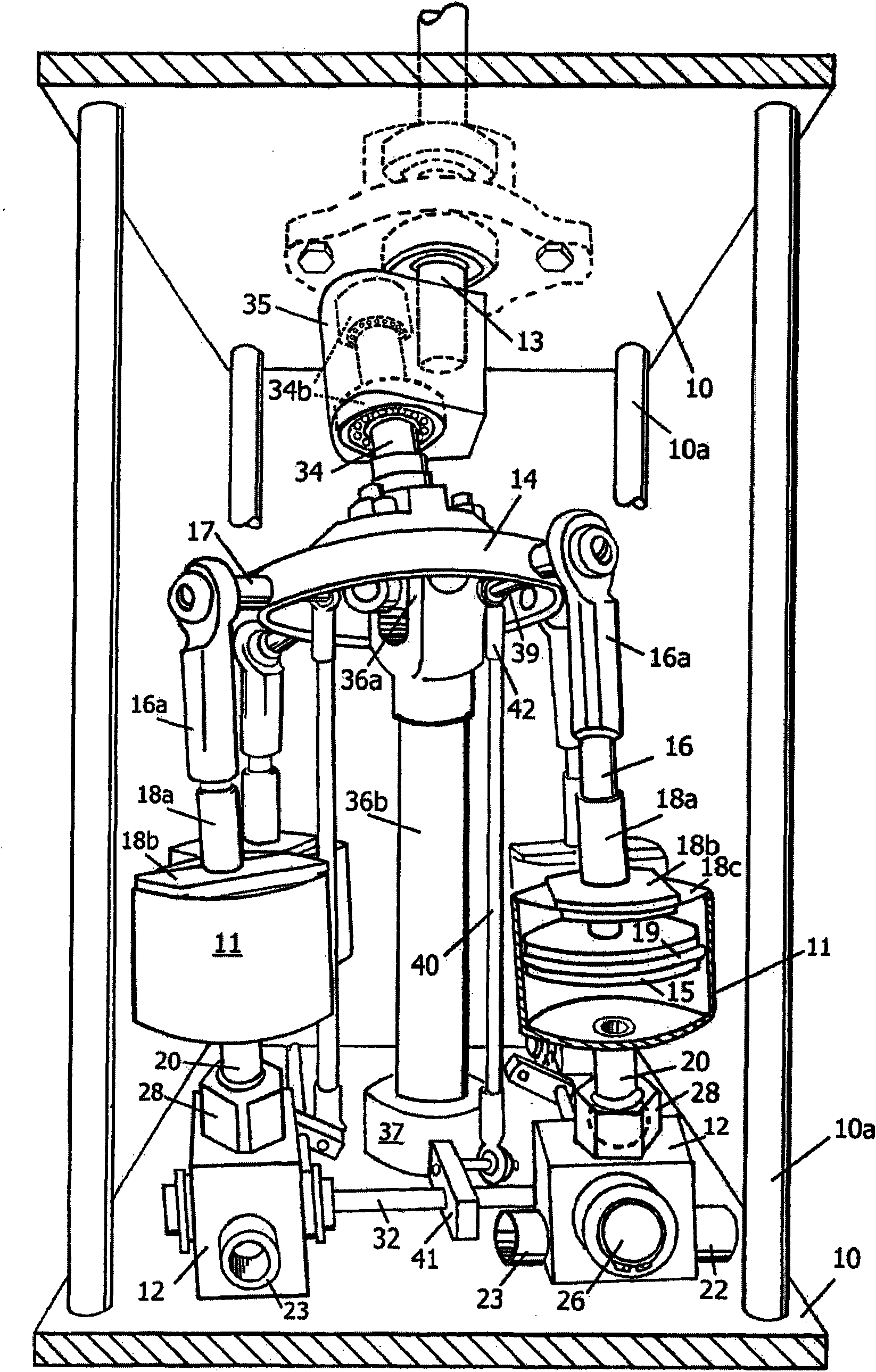

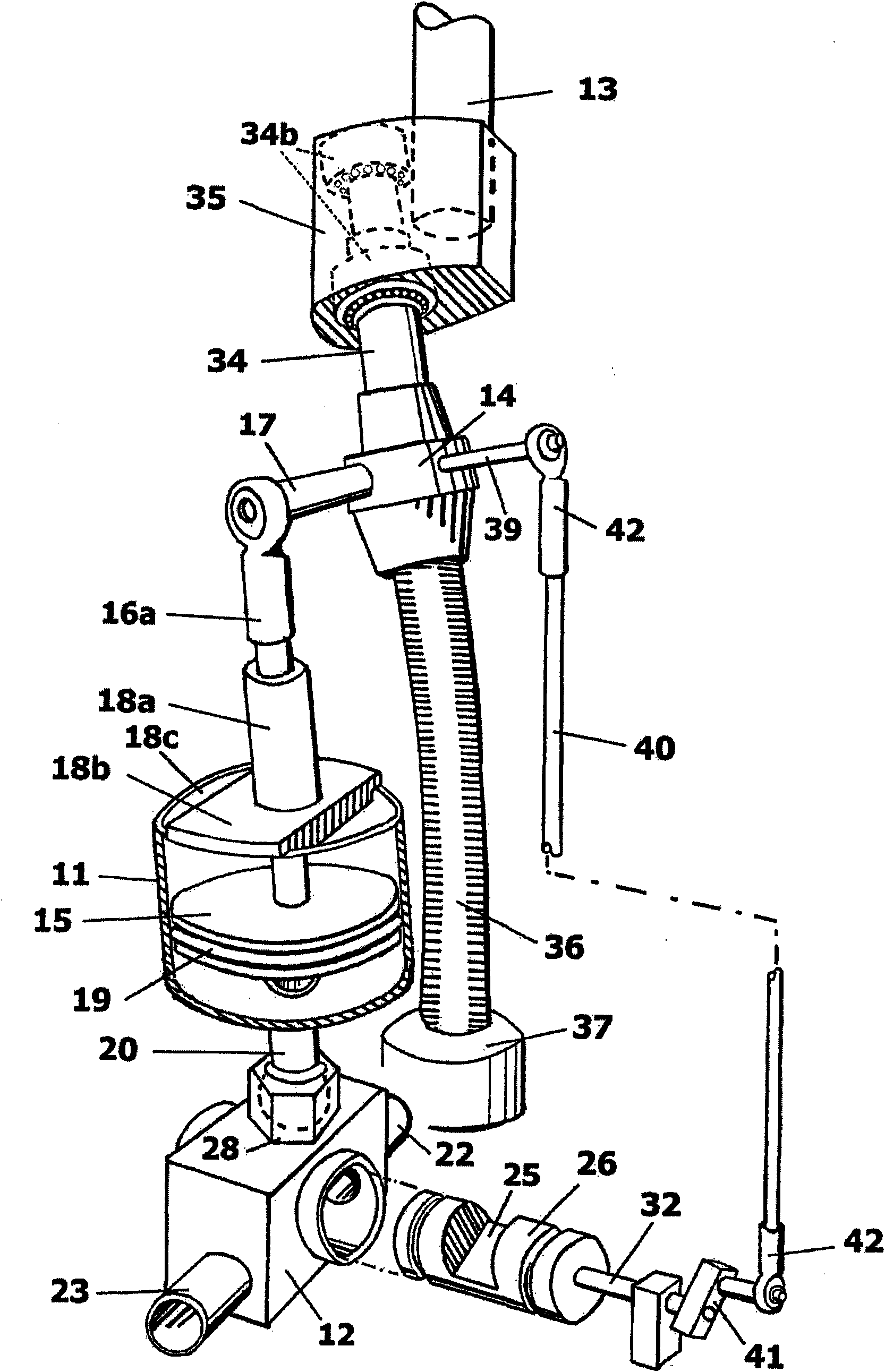

[0015] Refer to the diagram for details, figure 1 As a preferred embodiment there is shown an axial piston engine having a frame assembly with four legs 10a connecting two end walls generally indicated by the numeral 10 which operate in appropriate The relationship supports four basic components consisting of four identical articulated cylinder assemblies 11 pivotally connected to a fixed steam delivery valve assembly 12, an output crankshaft 13, an oscillating drive member 14 which drives Components interconnect the cylinder assemblies with the crankshaft.

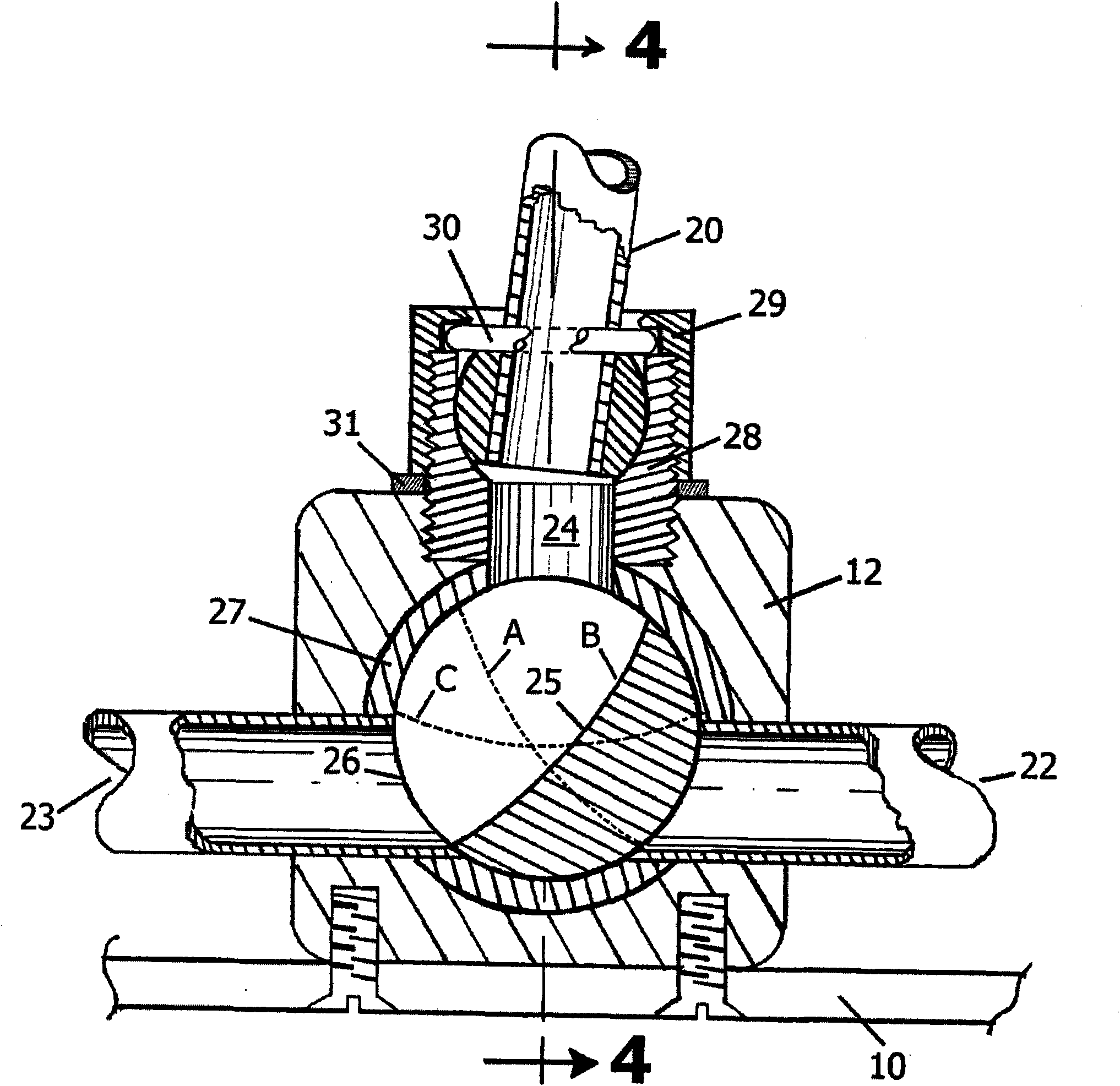

[0016] shown in figure 1 with figure 2 The cylinder assembly 11 in consists of a cylinder pivoted to the valve assembly 12 by a ball swivel sleeve joint 20 . Tube 20 is secured to the bottom of the cylinder, contains a hollow ball of durable metal or ceramic material and is pivotally mounted within an equally durable rotating sleeve joint 28 which is replaceably connected to valve 12. A piston disc 15 within the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com