External combustion engine and transmission mechanism thereof

A technology of transmission mechanism and external combustion engine, which is applied in the direction of machine/engine, hot gas variable capacity engine device, mechanical equipment, etc. The effect of long maintenance-free period, low lubrication requirements and easy start-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

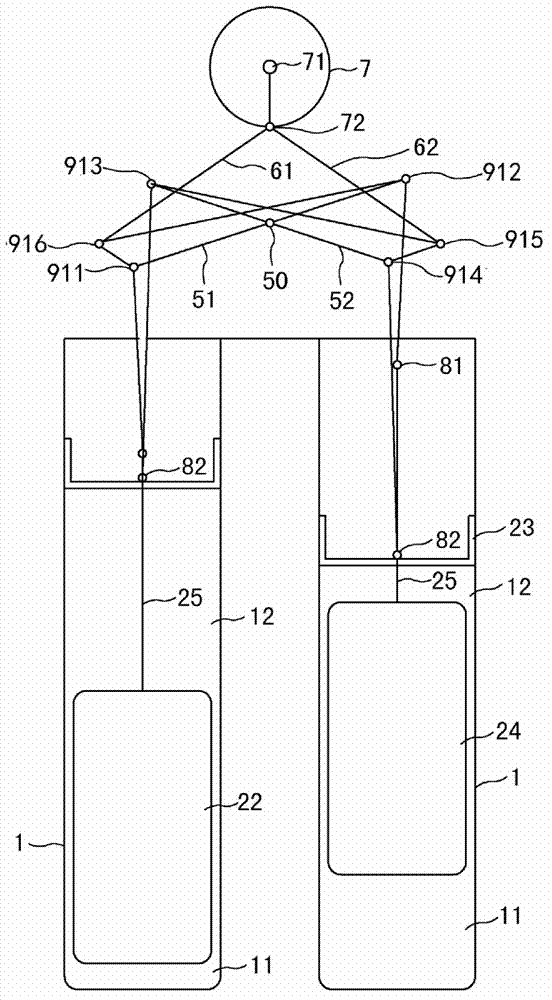

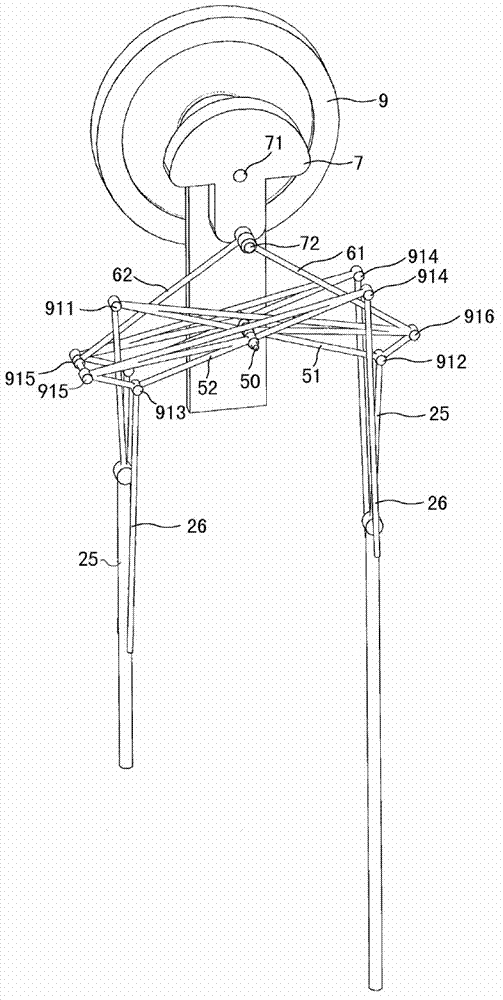

[0028] Such as Figure 1-Figure 5 As shown, the external combustion engine of the first embodiment of the present invention can be divided into three parts: the hot gas assembly, the crankshaft 7 and the transmission mechanism, wherein the transmission device includes two parts: a swing rod group and a connecting rod group.

[0029] 1. Hot air components

[0030] Firstly, the hot gas assembly can be the same as that of the external combustion engine in Document 1.

[0031] Such as figure 1 As shown, the hot gas components are two groups, and each group of hot gas components includes a cylinder 1, a heater, a regenerator and a cooler (not shown in the figure), and each cylinder 1 has an upper and a lower power piston 21, 23 and displacement pistons 22, 24; a cold cavity 12 is formed between the power pistons 21, 23 and the displacement pistons 22, 24, and a hot cavity 11 is formed between the displacement pistons 22, 24 and the cylinder (bottom); the thermal cavity 11 and the...

no. 3 example

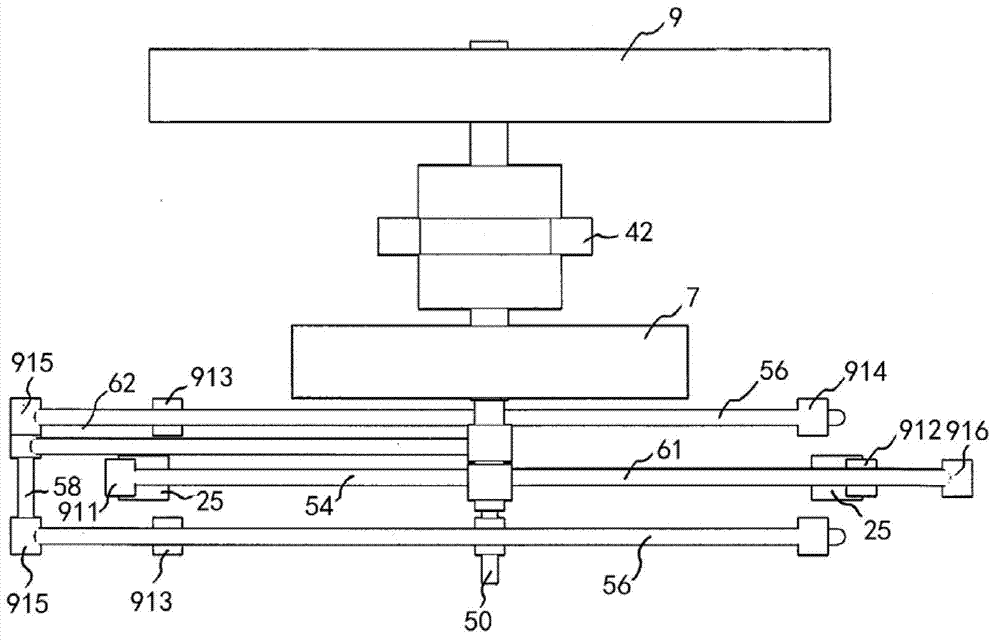

[0073] The difference between this embodiment and the first two embodiments lies in the difference in the transmission mechanism. The same parts as the first two embodiments will not be repeated, and the differences will be mainly introduced.

[0074] In this example,

[0075] Such as Figure 7 As shown, the left and right ends of the center swing rod 51 of the swing rod group respectively have a first hinge point 941 and a second hinge point 942 to hinge the upper end of the piston rod 25, while the two ends of the side swing rod 52 have a third hinge point respectively 943 and the fourth hinge point 944 hinge the upper end of the piston rod 26 .

[0076] Wherein, the first hinge point 941 and the second hinge point 942 are equidistant from the pivot shaft 50, and the third hinge point 943 and the fourth hinge point 944 are equidistant from the pivot shaft 50, so as to ensure that the two ends of the swing rod 51, 52 are balanced in force. . In this embodiment, the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com