Friction wheel transmission type ridge crushing box

A friction wheel drive, friction wheel technology, applied in the application, farming machinery, agricultural machinery and machinery and other directions, can solve the problems of poor interchangeability, difficult processing of gears, worm gears, and difficult assembly and maintenance, and meet the lubrication requirements. Low, easy to assemble and maintain, easy to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

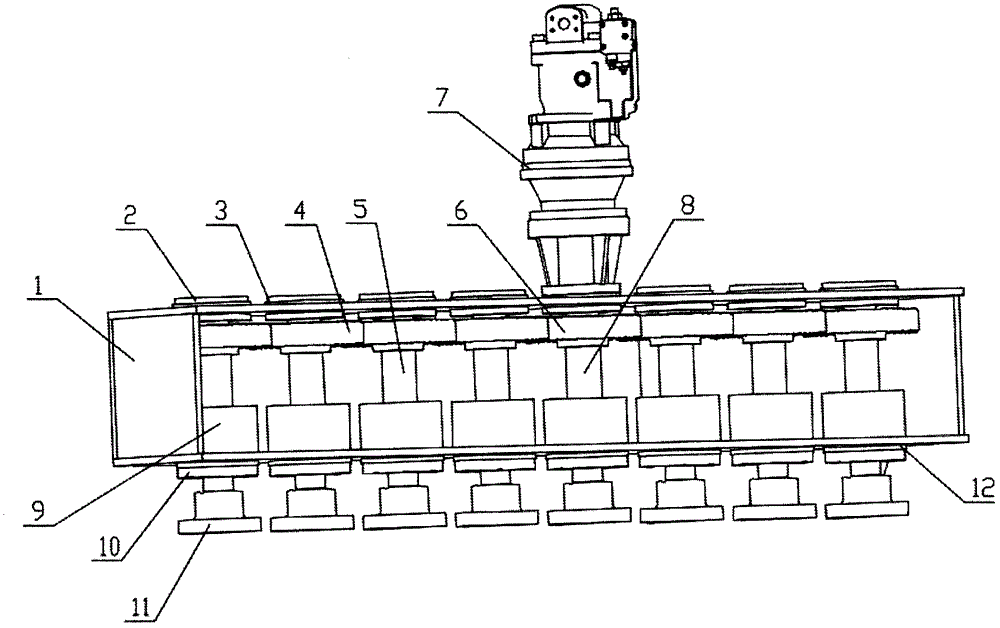

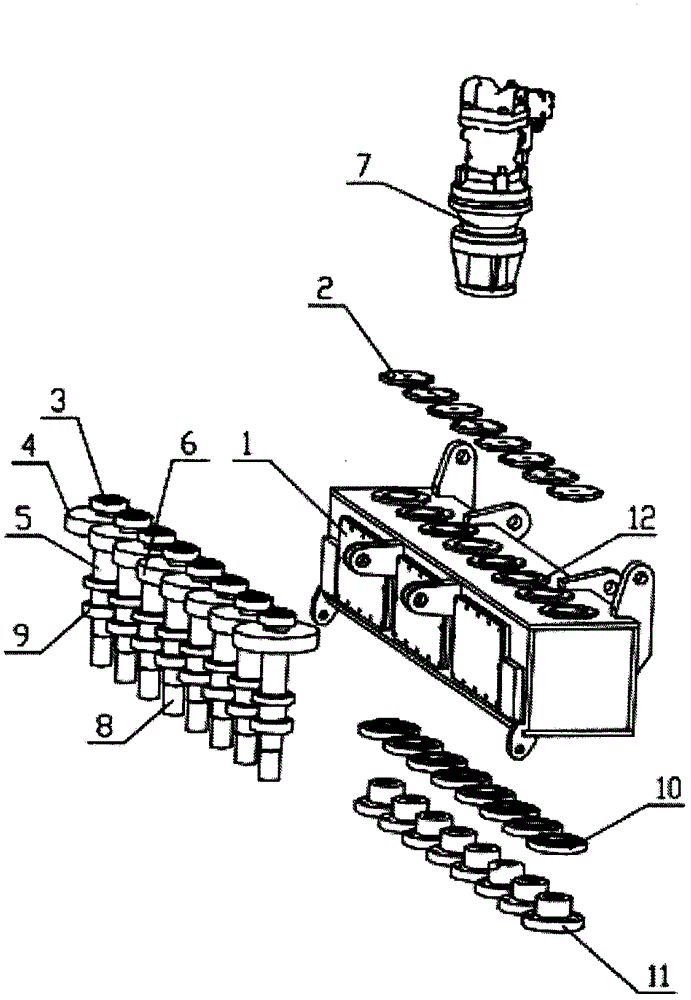

[0021] refer to figure 1 , figure 2 As shown, a friction wheel transmission powder ridge box includes friction wheels, bearing caps 2, 10, shafts, bearings 3, 9, a casing 1 provided with a bearing seat 12, and a coupling 11. The friction wheels include active Friction wheel 6, driven friction wheel 4, the shaft includes a driving shaft 8, a driven shaft 5, the driving friction wheel 6 is fixedly connected with the power source 7, the shaft and the friction wheel are fixedly connected with the same axis, supported by bearings Fixed on the bearing seat 12 provided on the box body 1, the bearing caps 2, 10 are connected with the bearing seat 12 provided on the box body 1 through fasteners, and the adjacent friction wheels are pressed against each other. The coupling 11 Connect with auger bit. When the power source 7 drives the driving friction wheel 6 and the driving shaft 8 to rotate, the corresponding driven friction wheel 4 is driven to rotate through the friction wheel tra...

Embodiment 2

[0026] The difference from Embodiment 1 is that in this embodiment, the driven friction wheel 4 can be set to have different diameters as required, and the power can be distributed to different driven shafts 5 according to the required speed and torque. As the driven friction wheel 4 with a larger diameter than the active friction wheel 6, it will obtain a smaller rotating speed and a larger torque than the active friction wheel 6; otherwise, it will obtain a larger rotating speed and a smaller torque than the active friction wheel 6 .

Embodiment 3

[0028] The difference from Embodiment 1 is that in this embodiment, the two adjacent friction wheels drive the auger bit to rotate in opposite directions, and the auger bit is correspondingly provided with opposite helical blades according to the direction of rotation. In this way, the two adjacent auger bits rotate and cooperate with each other, which can further improve the effect of deep plowing and deep loosening of the auger bits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com