Pulse knock rotor spindle engine

A technology of pulse detonation and engine, which is applied in the direction of engine components, engine cooling, machine/engine, etc. It can solve the problems of single use and high noise, and achieve the effect of wide application and overcoming huge noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

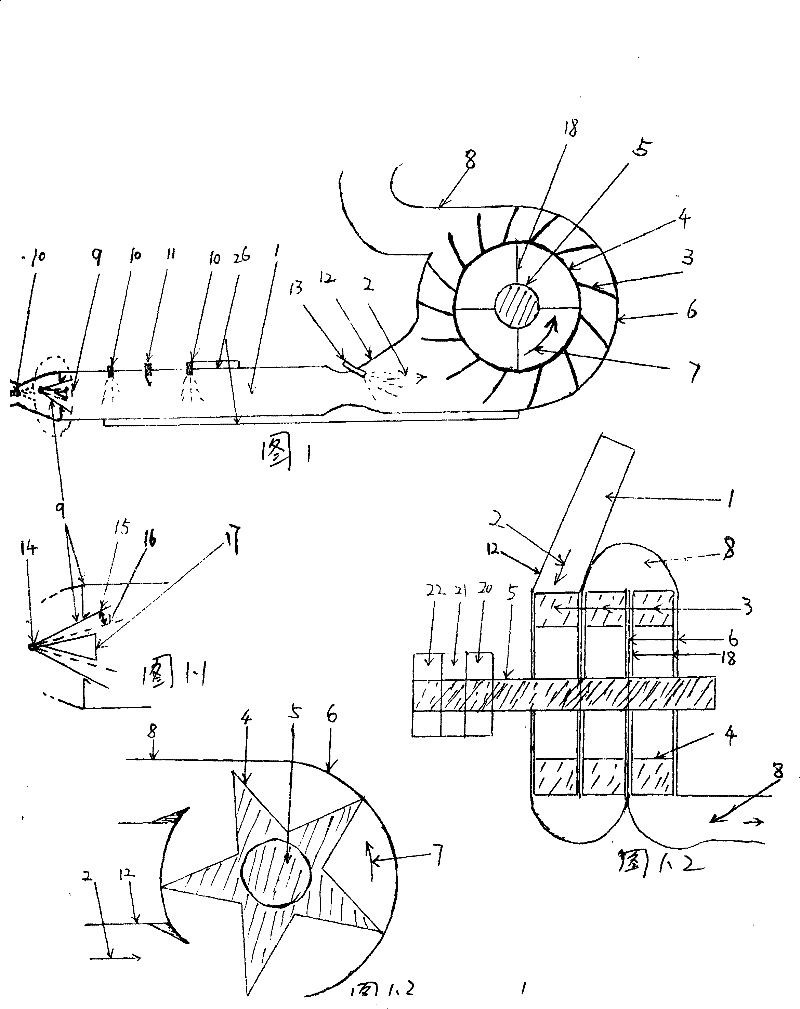

[0033] Embodiment 1: only have the pulse detonation rotor shaft motor of a pulse detonation motor: (as attached figure 1 , attached Figure 1.2 ) is mainly composed of a pulse detonation engine 1 with an intake valve 9 and a three-stage impeller rotor 4 driving an output shaft 5, etc., and its working process is that the air in the pulse detonation engine 1 is mixed with the fuel injected by the fuel nozzle 10 , the igniter 11 ignites the pulse detonation engine 1 to work, and the propelling gas 2 produced completely enters the casing 6 connected to it through the propelling gas ejection port 12. There is a water nozzle 13 in the propelling gas ejection port 12, and the ejected The atomized water can absorb the heat energy in the high-temperature and high-pressure propellant gas 2 and turn it into water vapor to increase the thrust of the propellant gas 2. The rest of the water can continue to evaporate in the shell 6 to cool down the engine. 6. Push the blade 3 on the impel...

Embodiment 2

[0034] Embodiment 2: a kind of pulse detonation rotor shaft engine that uses hydrogen and oxygen to work completely: (as attached figure 1 ) The original structure in the specific embodiment 1 remains unchanged, but on its basis, the upstream of the intake valve 9 of the pulse detonation engine 1 is airtightly connected with the hydrogen supply pipe, the gas supply regulation system, and the hydrogen cylinder (not shown) , the upstream of nozzle 10 is airtightly connected (not shown) with oxygen supply pipe and gas supply regulation system, oxygen bottle, and makes the hydrogen / oxygen=2 / 1 (mol ratio) that enters pulse detonation engine 1 by gas supply regulation system , and the rest of the working process is identical with that in specific embodiment 1. Make pulse detonation engine 1 become the pulse detonation rocket engine (PDRE) that uses hydrogen, oxygen fuel by air-breathing pulse detonation engine (PDE) like this, make pulse detonation rotorshaft engine of the present ...

Embodiment 3

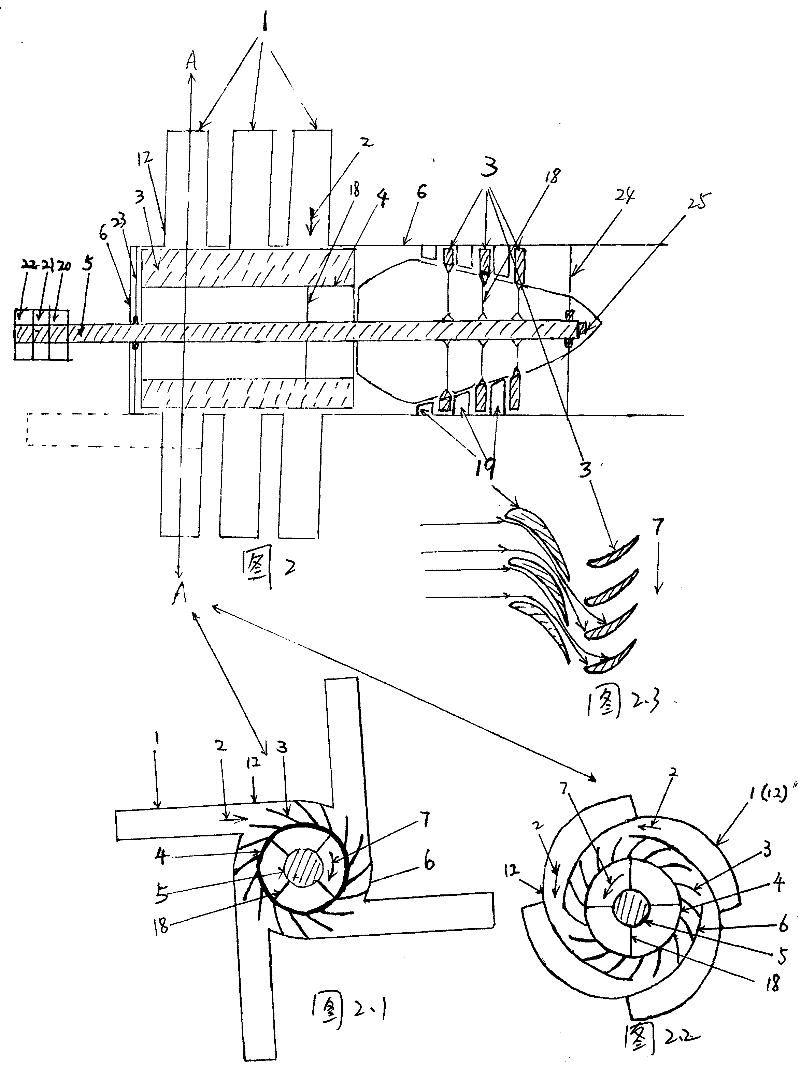

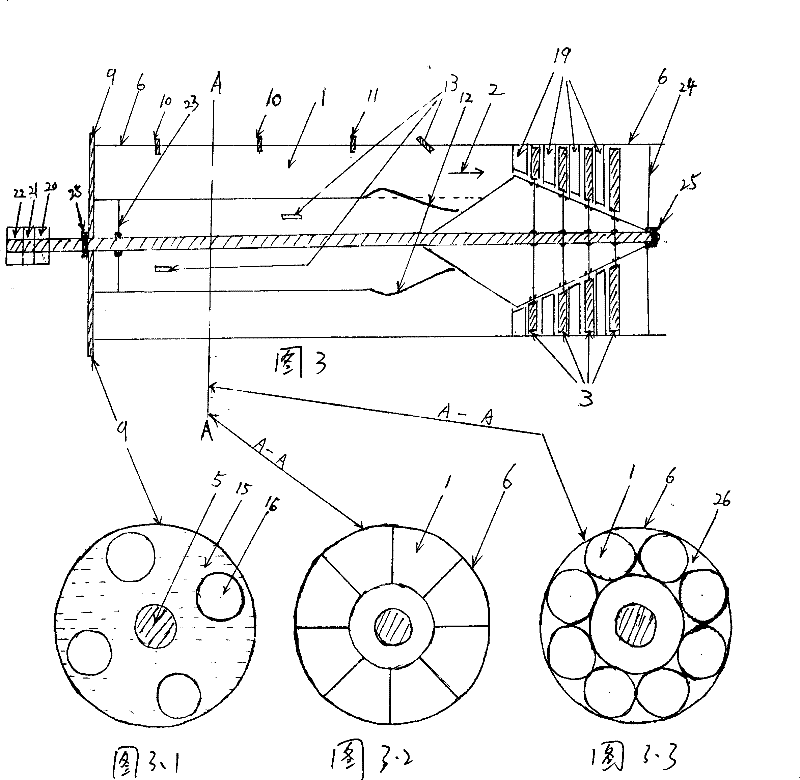

[0035] Embodiment 3: (as attached figure 2 ) The impeller driven by multiple pulse detonation engines, the turbo composite rotor type pulse detonation rotor shaft engine: its working process is the propelling gas 2 produced by 12 pulse detonation engines with intake valves 1 working, after water spraying After boosting, the propellant gas enters the same engine casing 6 connected to it through each propellant gas ejection port 12, and jointly tangentially pushes the impeller blades 3 to rotate the impeller rotor 4 and drive the output shaft 5 to rotate. At this time, the direction of the propellant gas 2 has been After being changed by the impeller blades 3, the turbine blades 3 of the downstream turbine rotor 4 are pushed again to make the turbine rotor 4 rotate. There are air guide stator blades 19 fixed on the inner wall of the casing 6 in front of the turbine blades 3 of each stage of the turbine rotor 4. In the figure, there are 1-stage impeller rotor and 3-stage turbine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com