A fuel injector disassembly test bench

A fuel injector and test bench technology, which is used in the testing of fuel injection devices, machinery/structural components, instruments, etc., can solve the problems of low efficiency of disassembly and assembly, high price, and inability to perform in one step, and achieve station positioning. Fast and accurate, low manufacturing cost, convenient and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

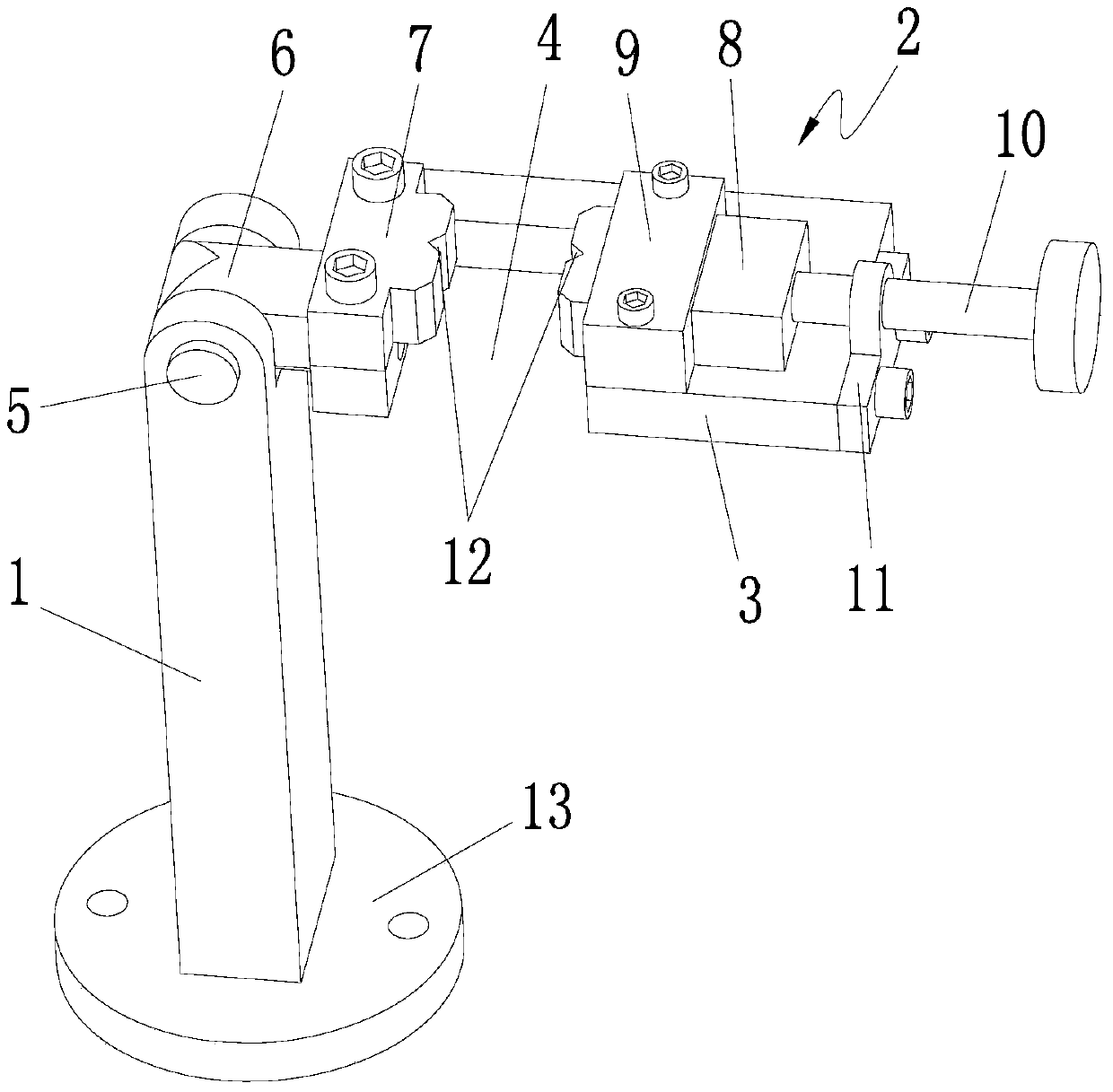

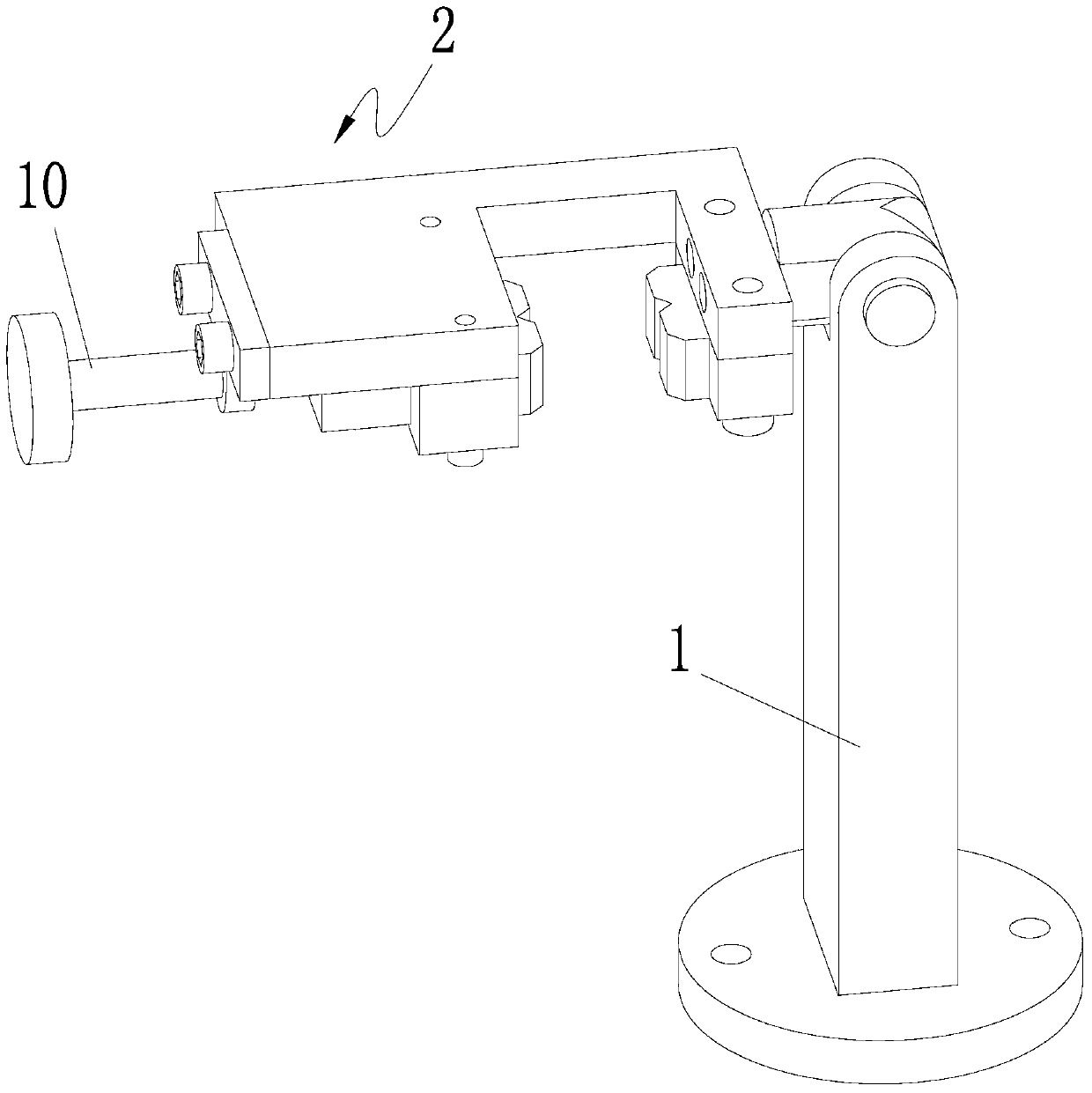

[0024] A fuel injector disassembly test bench, comprising a pillar 1, a turning arm 2 connected to the pillar and capable of turning over relative to the pillar, the turning arm has a fuel injector for clamping the fuel injector fixture.

[0025] Preferably, the turning arm includes a disassembly platform 3, one end of the disassembly platform is hinged on the pillar, and a jaw 4 is opened on the disassembly platform, and the fuel injector fixture is arranged on the jaw.

[0026] Preferably, a turning hinge shaft 5 is also provided, and the turning hinge shaft passes through the top of the pillar and one end of the dismounting platform to hinge the disassembling platform on the top of the pillar.

[0027] Preferably, the top of the pillar is provided with a hinged groove, and through holes are provided on the two side walls of the hinged groove, and a cantilever 6 protrudes from one end of the dismounting platform, and a hinged hole is provided on the cantilever, and the turni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com