Three dimensional hinge system for vehicle door

A car door, three-dimensional technology, applied in the field of car door and car body connection mechanism, can solve the problems of occupation, large car body effective space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

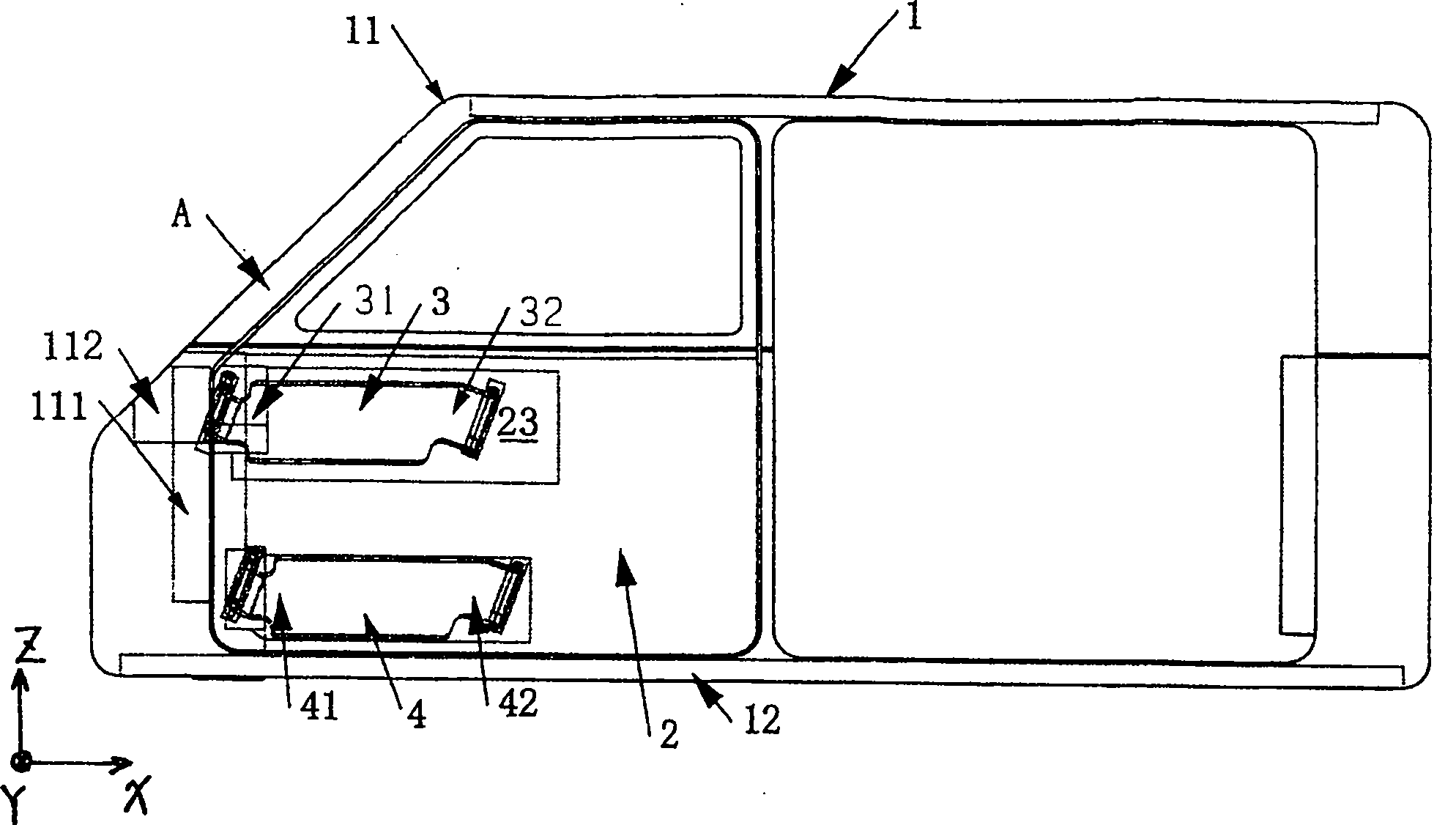

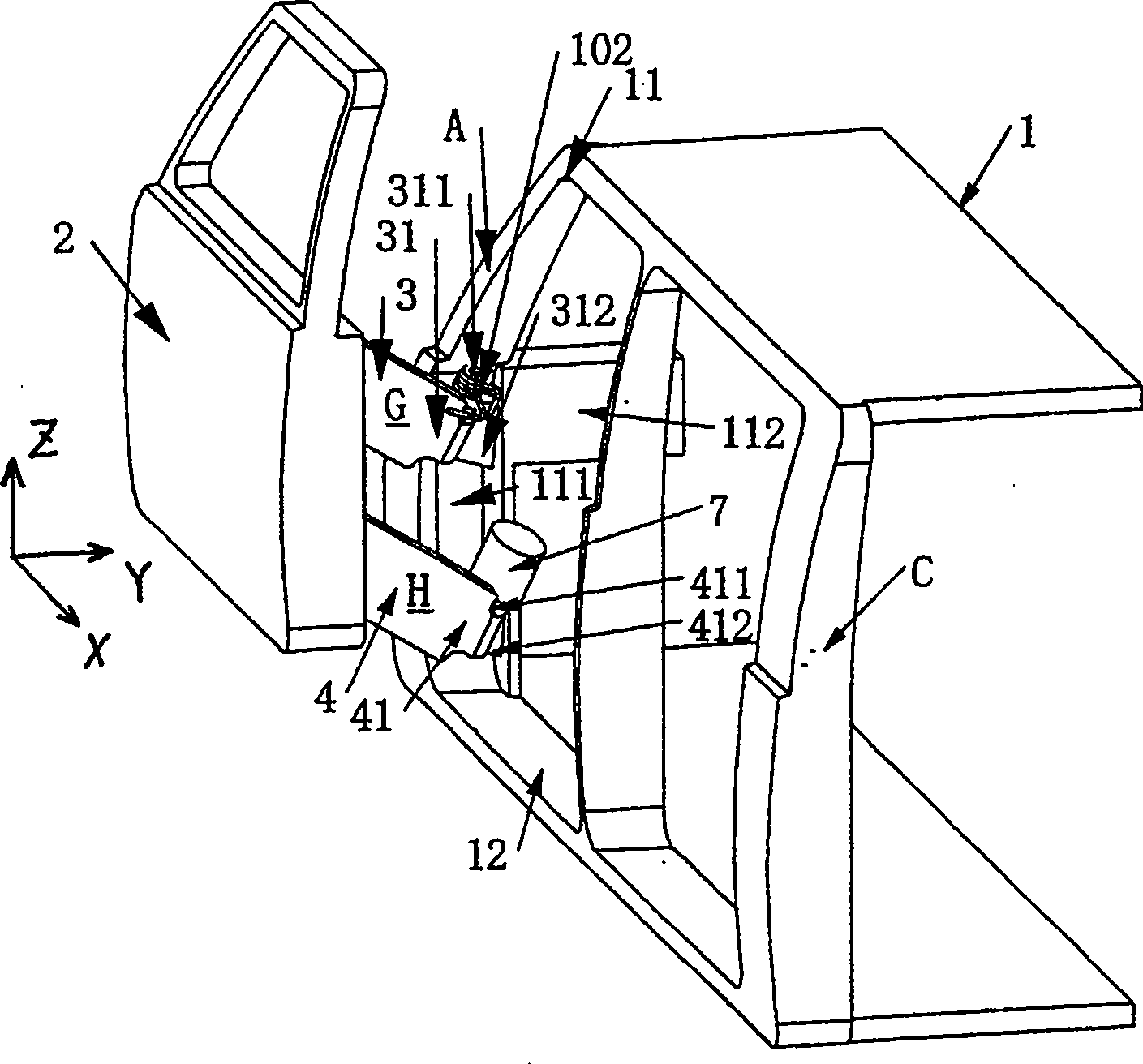

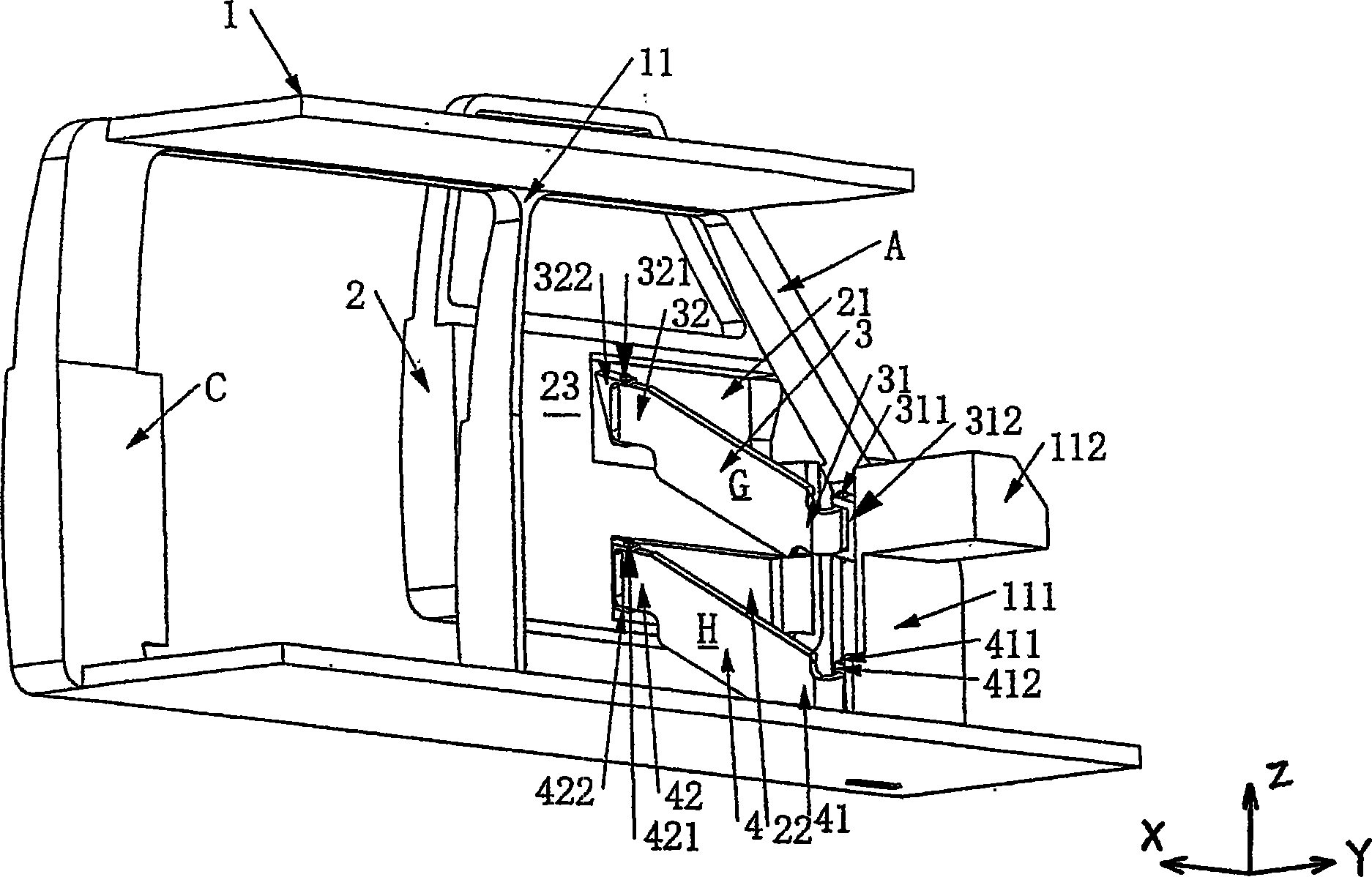

[0106] Such as figure 1 , as shown in 2, a kind of automobile door three-dimensional hinge system of the present invention can connect the car door 2 to the car door frame 11 of the vehicle body 1 in the form of a hinge shaft, and the part surrounded by the car door frame 11 is opened to allow the occupant to enter and exit the vehicle body 1 The car door opening of the door matches with the car door 2 when closing.

[0107] The dotted line in the figure is the part that is not visible in the main view. It can be seen from the figure that the present invention comprises:

[0108] The main link 3, the main link 3 includes a first end 31 and a second end 32, the first end 31 is similar in height to the lower section 111 of the A-pillar (front pillar) of the door frame 11 and the instrument panel 112 The position is connected, the second end 32 is connected with the upper part of the inner panel 23 of the door 2, such as image 3 , the height of the connection can be similar ...

Embodiment 2

[0119] Such as Image 6 Shown, when applying the present invention, also can make the top of the car door frame 11 of body body 1 recess a recessed position 13, roof cover 6 side edge recesses a recessed position 61, the car door window frame top of car door 2 then extends out and The baffle plate 24 matched with it, a fixed glass window 241 can be installed in the baffle plate 24 to increase the daylighting in the vehicle body body 1. At this time, the connecting positions of the two ends of the main connecting rod 1 are the same as those in Embodiment 1, but the axis lines of the first axis 311 and the axis lines of the second axis 321 are parallel to the Z axis. The connecting position connecting the first end 41 of the secondary connecting rod 4 and the body 1 can be set at the top of the door frame 11 close to the concave position 13 or other structural parts of the roof cover 6 , and the second connecting rod 4 is connected. The connection position between the end porti...

Embodiment 3

[0121] Such as Figure 7 with Figure 8 As shown, the main link 3 can also be made into a type with upper and lower branches at the second end 32, and the two branches are respectively marked as 32A and 32B, and the corresponding hinge seats 322A and 322B are hinged respectively. It is connected to the top of the window frame of the car door and the top of the inner panel of the car door 2. The shape of the upper branch 32A and its vicinity can match the shape of the corresponding part of the A-pillar and the top of the door frame 11, that is, the upper branch 32A of the main link 3 in this form can be hidden in the door 11 when the door 2 is closed. inside of the window frame. The structure of this form is equivalent to increasing the effective length of the second shaft (the mating length of the second shaft and related parts) to increase the stability of the hinge mechanism. The position where the first end 41 of the auxiliary link 4 is connected can also be set on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com