Sliding piece type compressor with cylinder rotating with rotor

A compressor and sliding vane technology, applied in the field of compressors, can solve problems such as the unbalanced quality of the crankshaft affecting smooth operation, large mechanical friction between the sliding vane and the rotor cylinder, complex structure of the screw compressor, etc., and achieves the convenience of gap adjustment and control , Simplified structure and support methods, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

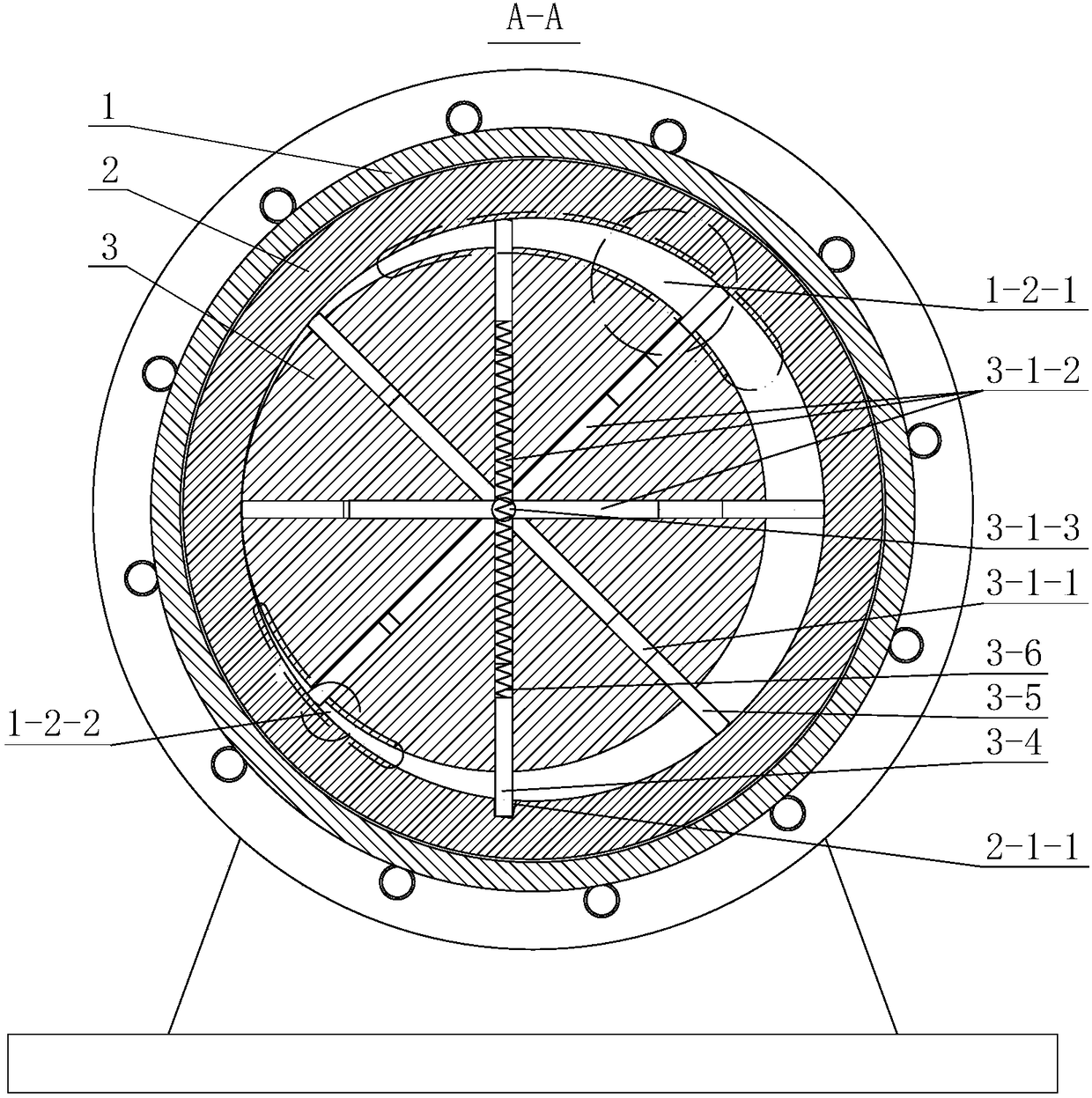

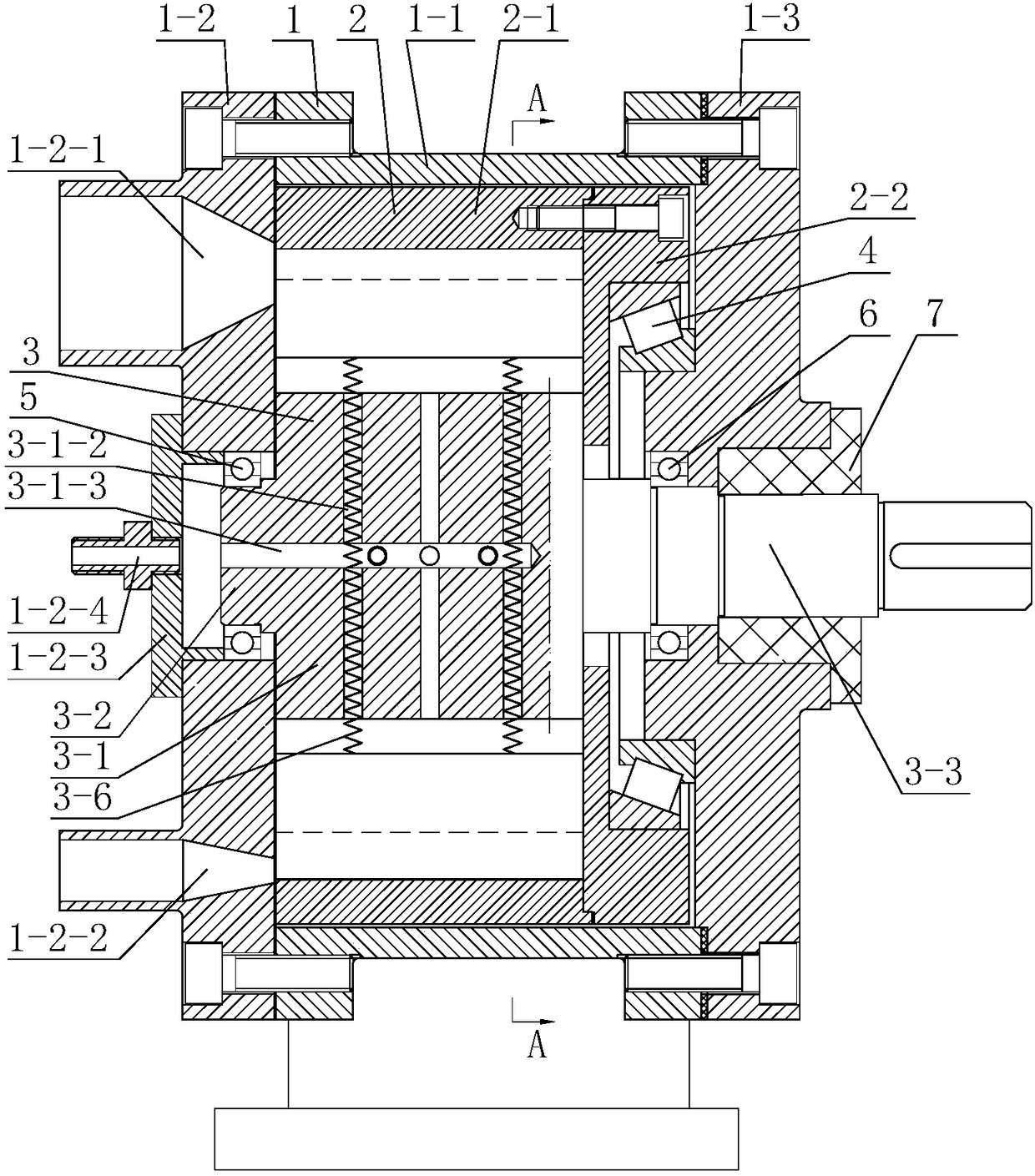

[0013] A sliding vane compressor in which the cylinder rotates with the rotor, comprising a cylindrical casing 1 with a base, a moving cylinder 2 is arranged inside the cylindrical casing 1 and the cylindrical casing 1 and the moving cylinder 2 are arranged coaxially, and the A rotor 3 is provided in the moving cylinder 2 and the moving cylinder and the rotor 3 are arranged eccentrically. An air inlet 1-2-1 and an air outlet 1-2-2 are arranged on the left end surface of the casing, and the inlet The air port 1-2-1 is located in the crescent-shaped gap area between the moving cylinder and the rotor, along the rotor rotation direction from small to large, and the air outlet 1-2-2 is located in the crescent-shaped gap between the moving cylinder and the rotor The position from large to small along the direction of rotation of the rotor in the area; ≥8 even-numbered axial rectangular grooves 3-1-1 are evenly distributed on the rotor 3, and in each group of opposite rectangular groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com