Planetary transmission mechanism for double-faced grinding/polishing machine

A double-sided grinding and planetary transmission technology, applied in grinding/polishing equipment, grinding machine parts, grinding drive devices, etc., can solve problems such as increasing the difficulty of parts processing, rising material costs, and increasing parts size, etc. Achieve the effect of extending service life, reducing material cost and improving contact stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

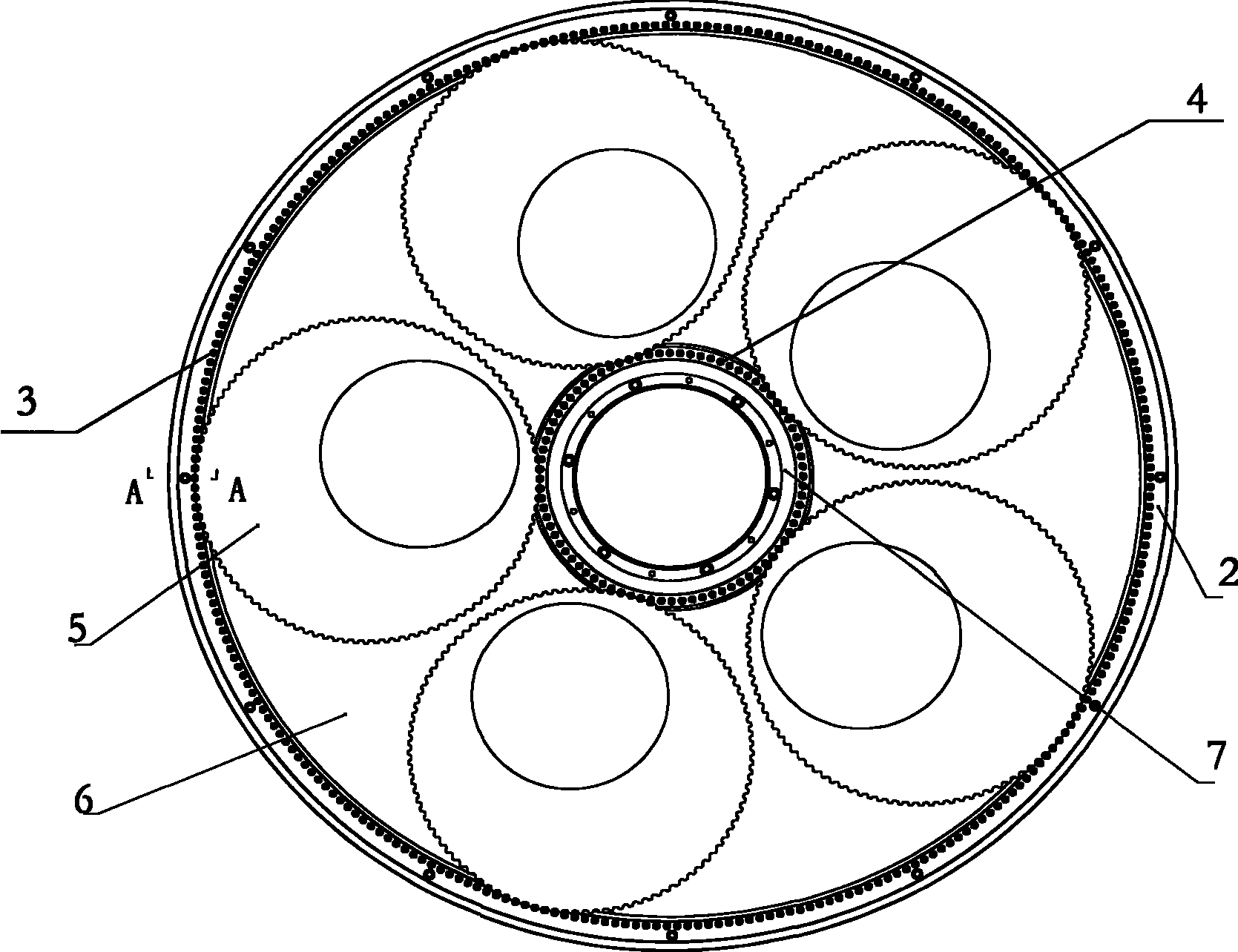

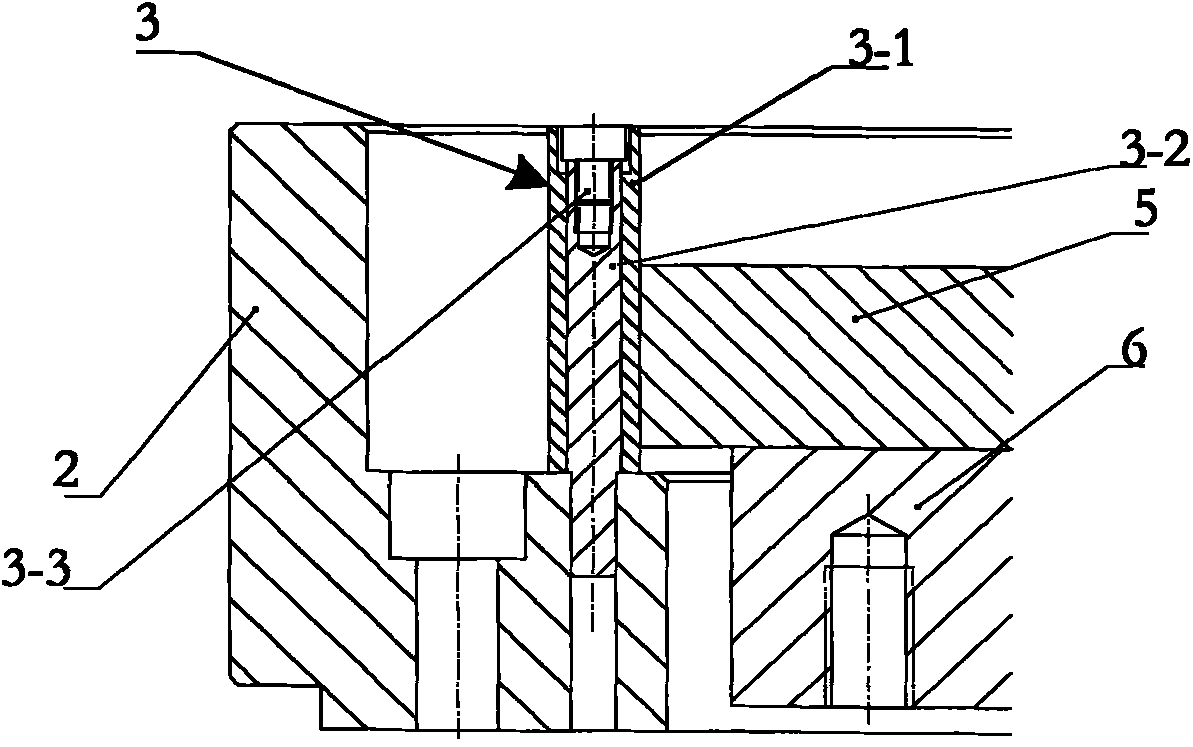

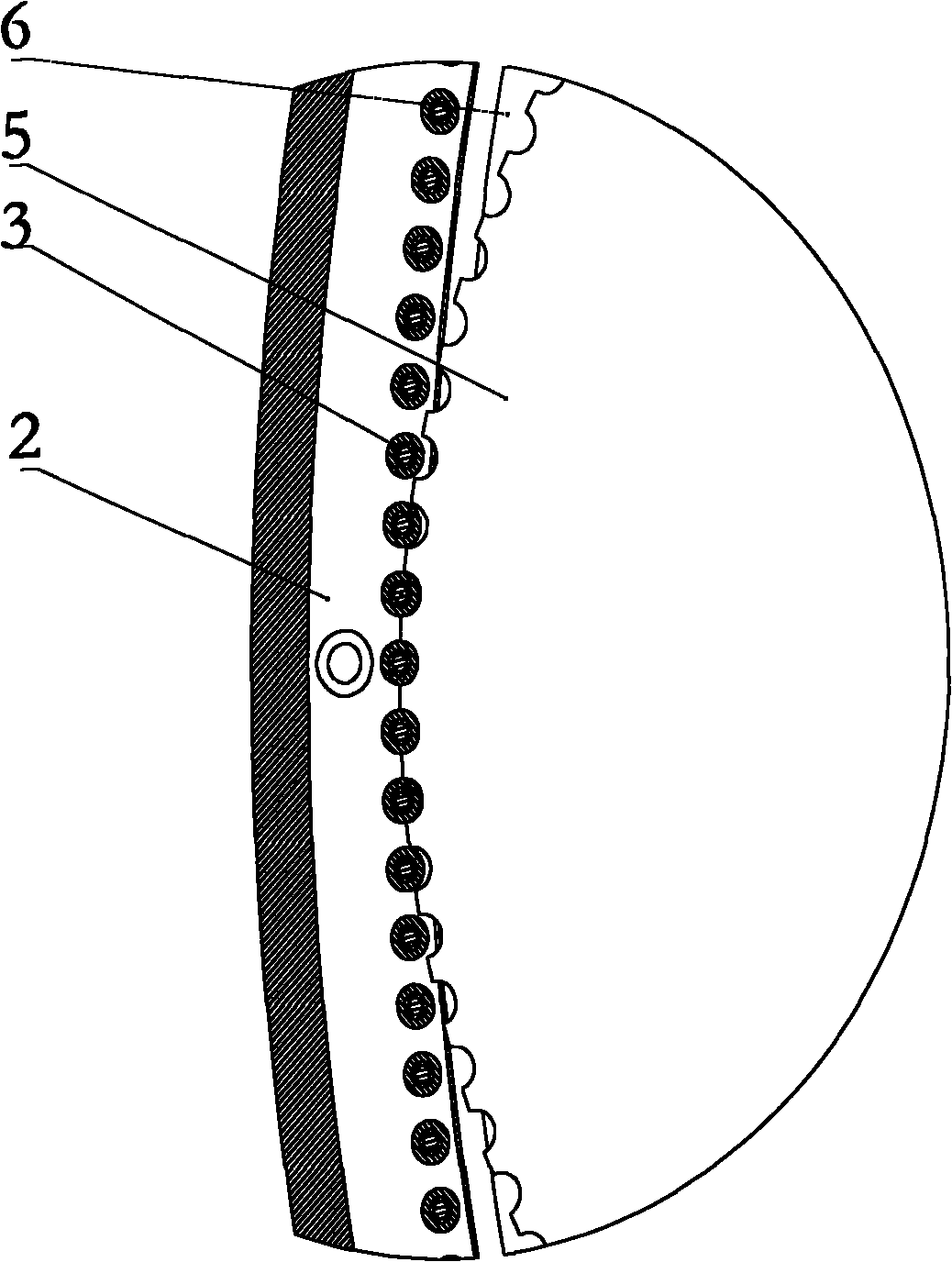

[0028] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a planetary transmission mechanism for a double-sided grinding / polishing machine includes a planetary gear 5 meshing with the ring gear 2, the planetary gear 5 is meshing with the sun gear 7, and the planetary gear 5 is arranged on the lower plate 6 , the inner side of the ring gear 2 is provided with a circle of ring gear pin teeth 3, and there is a tooth pitch between the two ring gear pin teeth 3, and the ring gear 2 is connected to the planetary wheel 5 through the ring gear pin teeth 3 engage. The gear of described planetary wheel 5 is arc tooth. The ring gear pin tooth 3 includes a ring gear pin shaft 3-1 and a ring gear pin sleeve 3-2, and a ring gear pin sleeve 3-2 is arranged outside the ring gear pin shaft 3-1, and a ring gear pin sleeve 3-2 is arranged outside the ring gear pin shaft 3-1. The top of the shaft 3-1 is provided with a ring gear pin sleeve limit screw 3-3. Ring gear pin shaft 3-1 is ...

Embodiment 2

[0029] Embodiment 2: the same as Embodiment 1, the difference is that a ring of sun gear pin teeth 4 is provided on the outer surface of the sun gear 7, and there is a pitch between the two sun gear pin teeth 4, and the sun gear 7 meshes with the planetary wheel 5 through the sun gear pin teeth 3. The sun gear pin teeth 4 all include a sun gear pin shaft and a sun gear pin sleeve, a sun gear pin sleeve is provided outside the sun gear pin shaft, and a sun gear pin sleeve limiter is provided on the top of the sun gear pin shaft. screw. The pin shaft of the sun gear is fixedly connected on the base of the sun gear. The pin shaft of the sun gear is arranged parallel to the outer surface of the sun gear.

[0030] The pin tooth 3 of the ring gear and the pin tooth 4 of the sun gear are both composed of two parts, the outside is the pin sleeve, and the inside is the pin shaft. The lower end of the pin shaft and the ring gear seat adopt an interference fit, and the pin shaft is tig...

Embodiment 3

[0031] Embodiment 3: Same as Embodiment 1, except that the distance from the stop screw 3-3 of the ring gear pin sleeve to the inner shoulder of the ring gear pin sleeve 3-2 is 1.5-2 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com