Titanium Alloy Notched Bolts

A titanium alloy and notch technology, applied in the field of spacecraft structure, can solve the problems of unknown interruption performance, uncontrollable separation method, failure to meet the requirements of the connection and separation performance of the two halves of the fairing, and achieve enhanced separation performance and increased The effect of large size ratio and increased surface contact stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings.

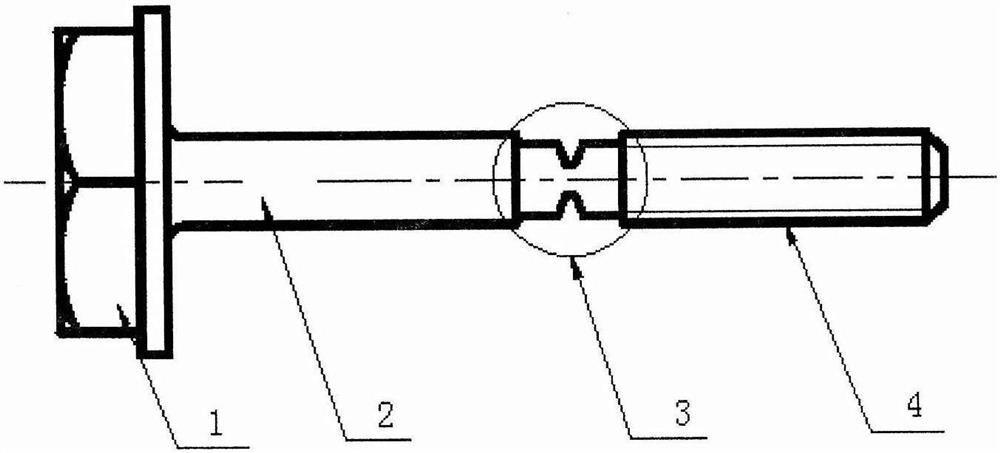

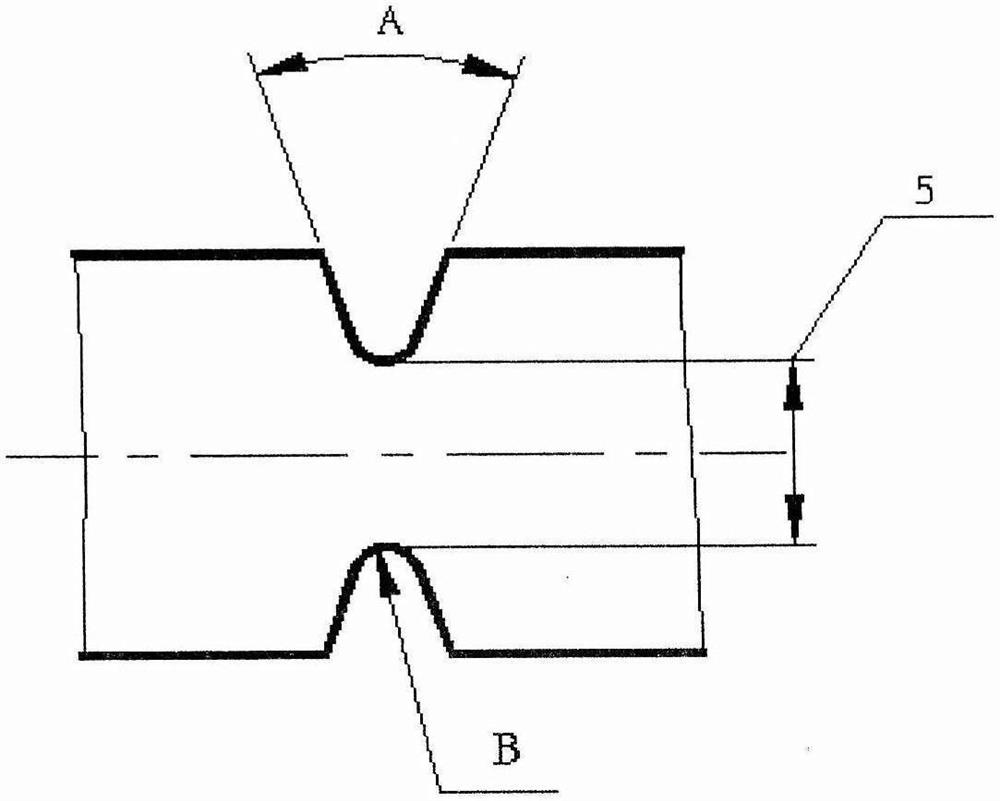

[0020] Such as figure 1 As shown, the titanium alloy recess bolt of the present invention includes bolt head 1 and screw 2; the upper portion of the bolt head 1 is a hexagonal shape, the lower portion of the bolt head 2 is a cylinder; the cylinder diameter is greater than the diameter of the hexagonal outer circle; screw 1 Mid-open recess 3; the bottom of the screw 1 is threaded 4, and the thread 4 is connected through the nut.

[0021] In this embodiment, the bolt tensile force is required to be 1.4 tons, and the material uses TB2 titanium alloy material. After solid solution, the aging heat treatment process, the design static indicator is achieved, and the static connection requirements of the long-range head longitudinal separation device are met.

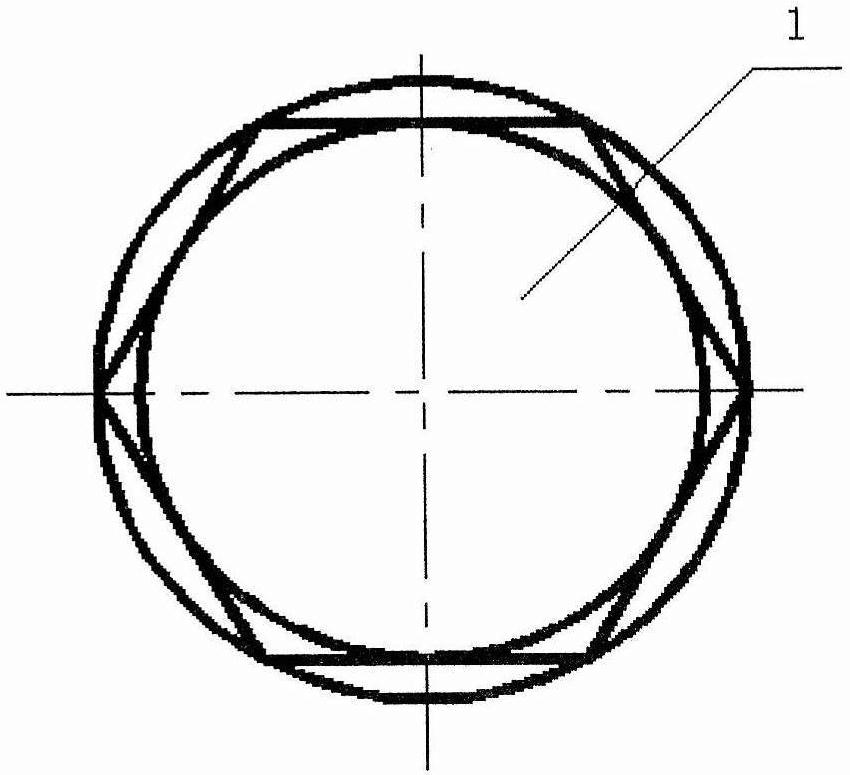

[0022] The bolt head 1 of the titanium alloy recess bolts of the present invention uses the mesh, and the specific structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com